Method for fabricating artificial dimension stones

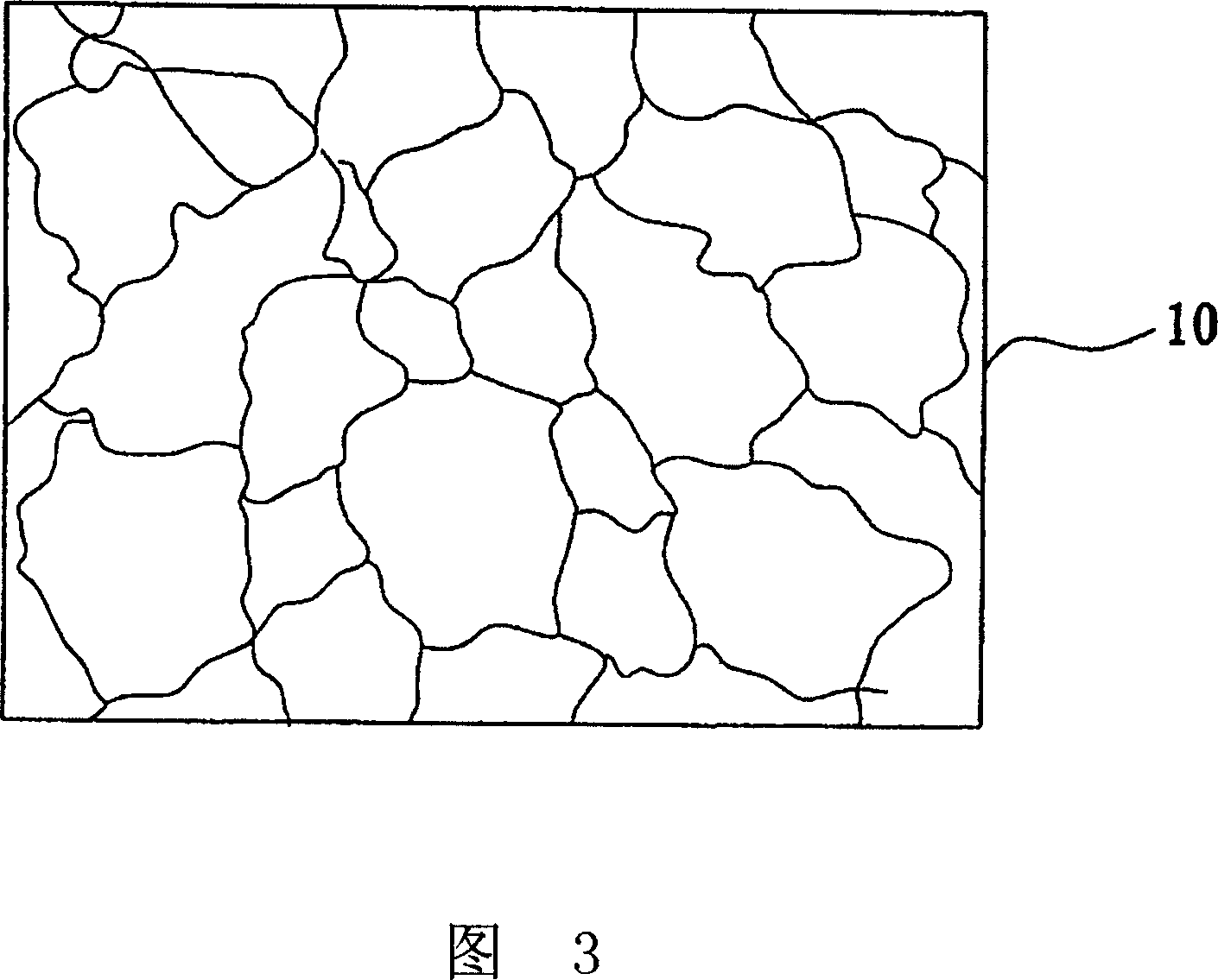

A technology of artificial stone and manufacturing method, which is applied in the direction of manufacturing tools, decorative arts, ceramic molding machines, etc., can solve the problems of lack of change in beauty, easy breakage, and easy deformation of artificial stone 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

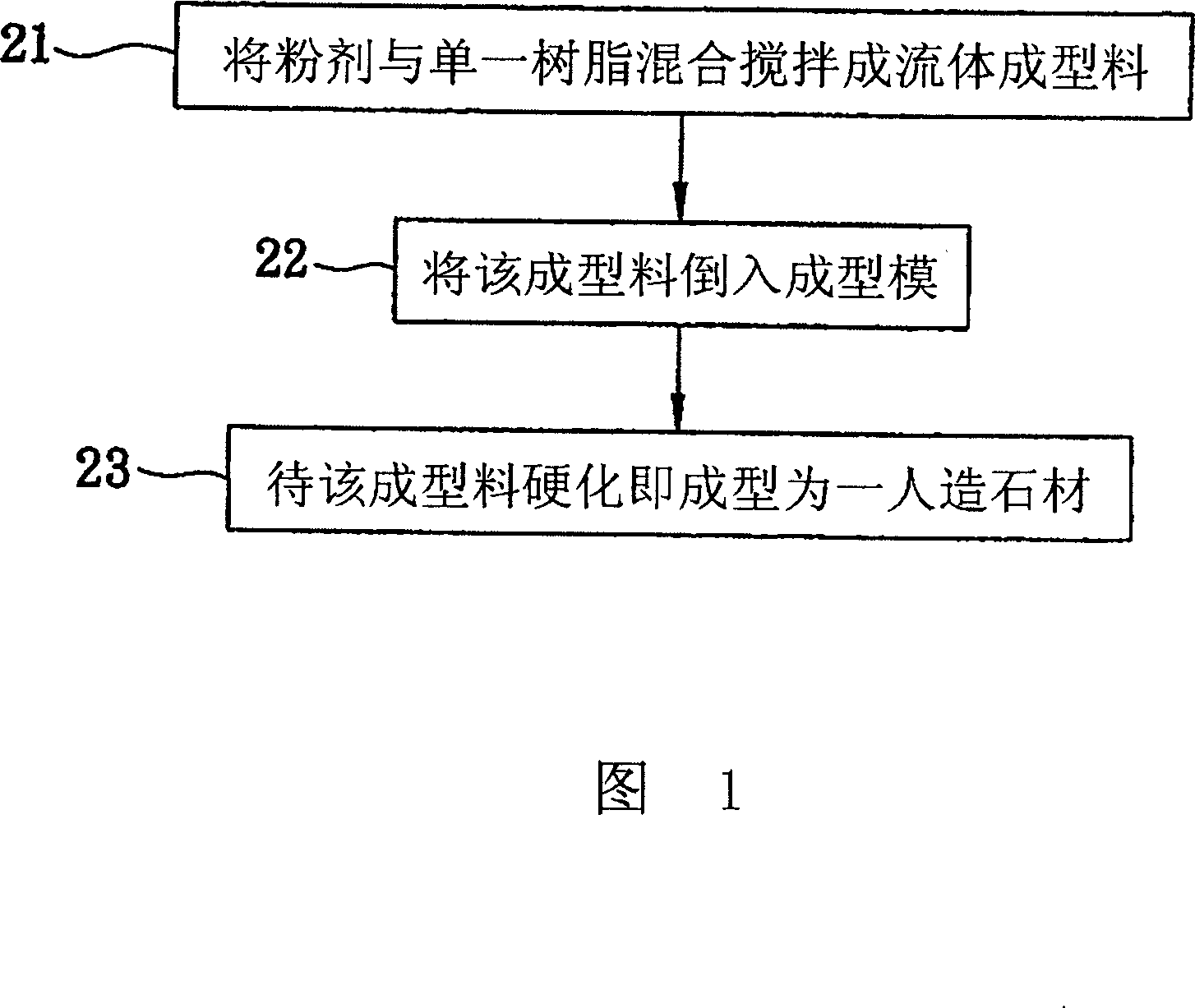

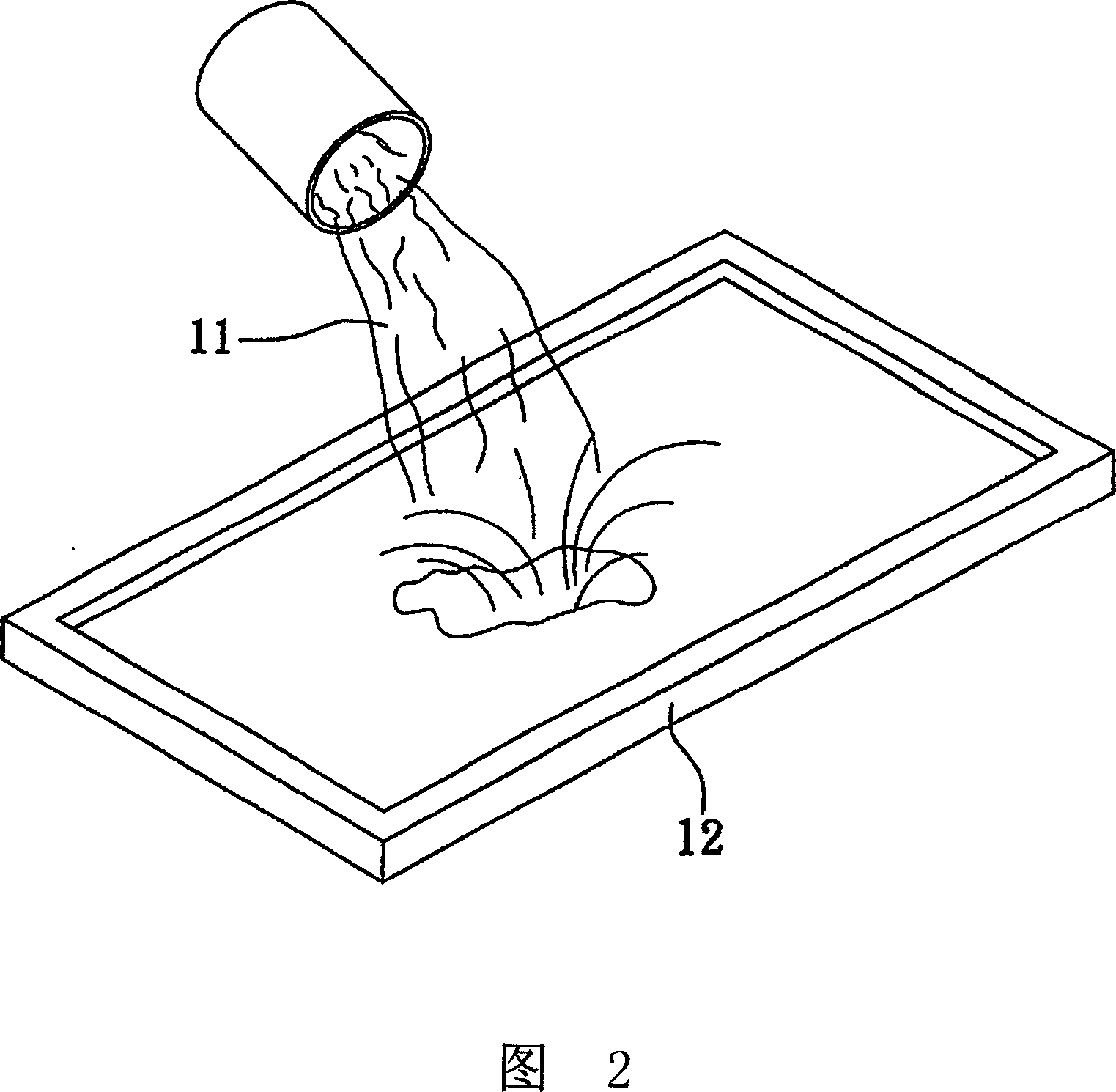

[0029] In order to illustrate the manufacturing method of the present invention and its characteristics and effects in detail, two preferred embodiments of the present invention are listed below and described with accompanying drawings.

[0030] As shown in FIGS. 4-7 , a first preferred embodiment of the manufacturing method of the artificial stone of the present invention includes steps 31-37.

[0031] As shown in Figure 4, step 31 is to prepare a mixed resin, which is to mix and stir a flexible resin and a rigid resin in a ratio of 20% to 80% by weight: 80% to 20% to form a mixed resin evenly, then the mixed resin It will have both soft and hard characteristics.

[0032] In the present invention, flexible resin and rigid resin all can be purchased from the market, such as the resin that model is MF-01, MF-453M, wherein the composition of the resin that model is MF-01 is maleic two or Malin ( MALEIC ANHYDRIDE) 30%, propylene glycol (PROPYLENE GLYCOL) 15%, ethylene glycol (ET...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com