Fiber cotton and its producing method

A manufacturing method and fiber cotton technology, applied in the field of fiber cotton, can solve the problems of complicated shaping process equipment, etc., and achieve the effects of stable arrangement sequence, smooth fiber cotton texture on both sides, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A fiber cotton manufacturing method, the technological process sequentially includes: material cutting, carding, forming, heat-drying bonding, shaping, cutting, etc., which are introduced as follows respectively, and the embodiments are given as non-limiting examples :

[0022] Raw material opening: 10% to 80% low-melt fiber and 90% to 20% of other fibers are formulated as raw materials. This embodiment uses 20% low-melt fiber LMF (4080 low-melt fiber) and 80% polyester (PET) Fibers (all available in the market) are mixed and loosened (generally completed by a feeder mixer), and after repeated mixing;

[0023] Sending into the carding process: This process can generally be completed by a carding machine, after the mixed fibers are carded to make them smooth and even, and the structural force between the fibers is strengthened to become a mesh;

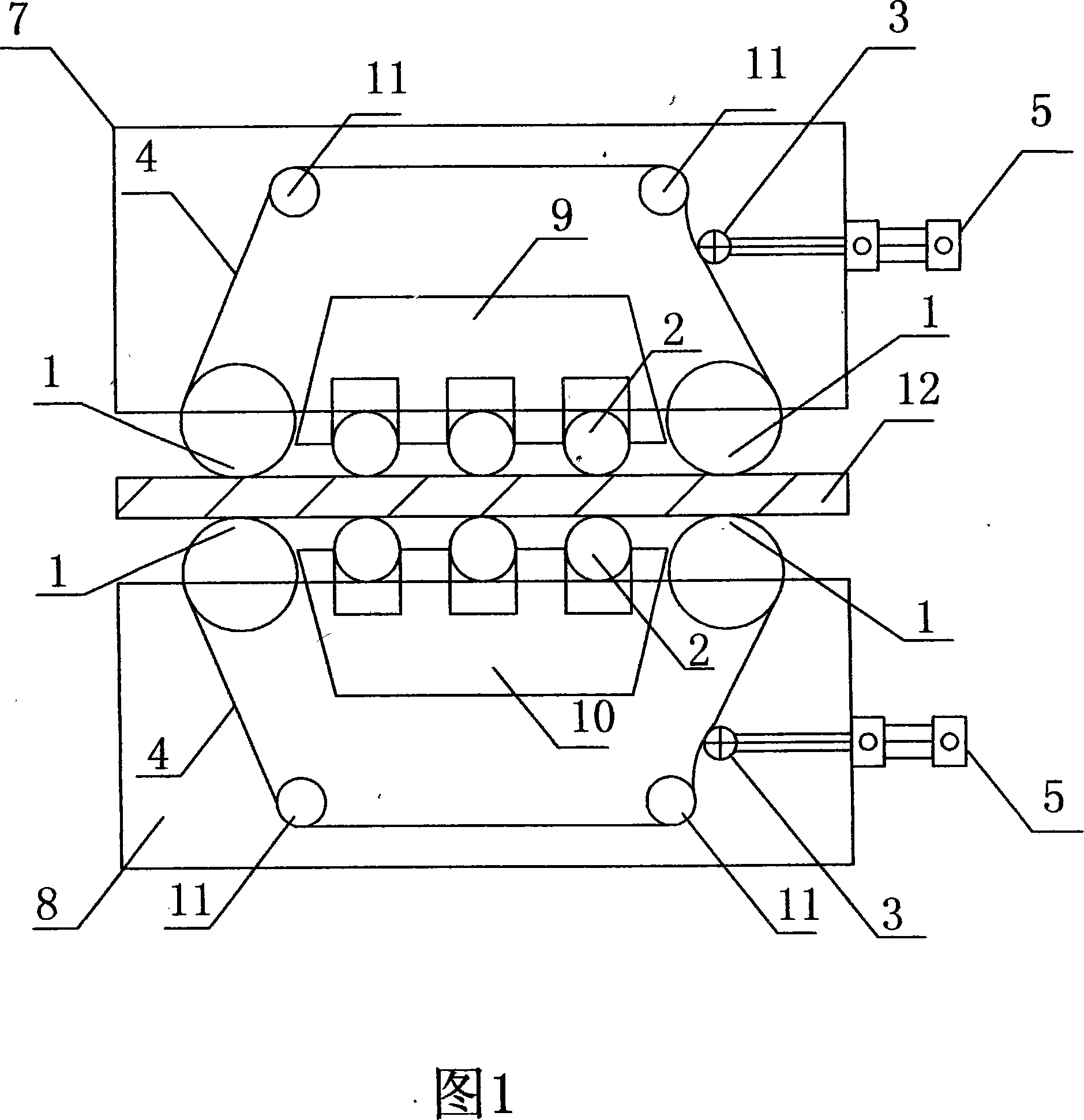

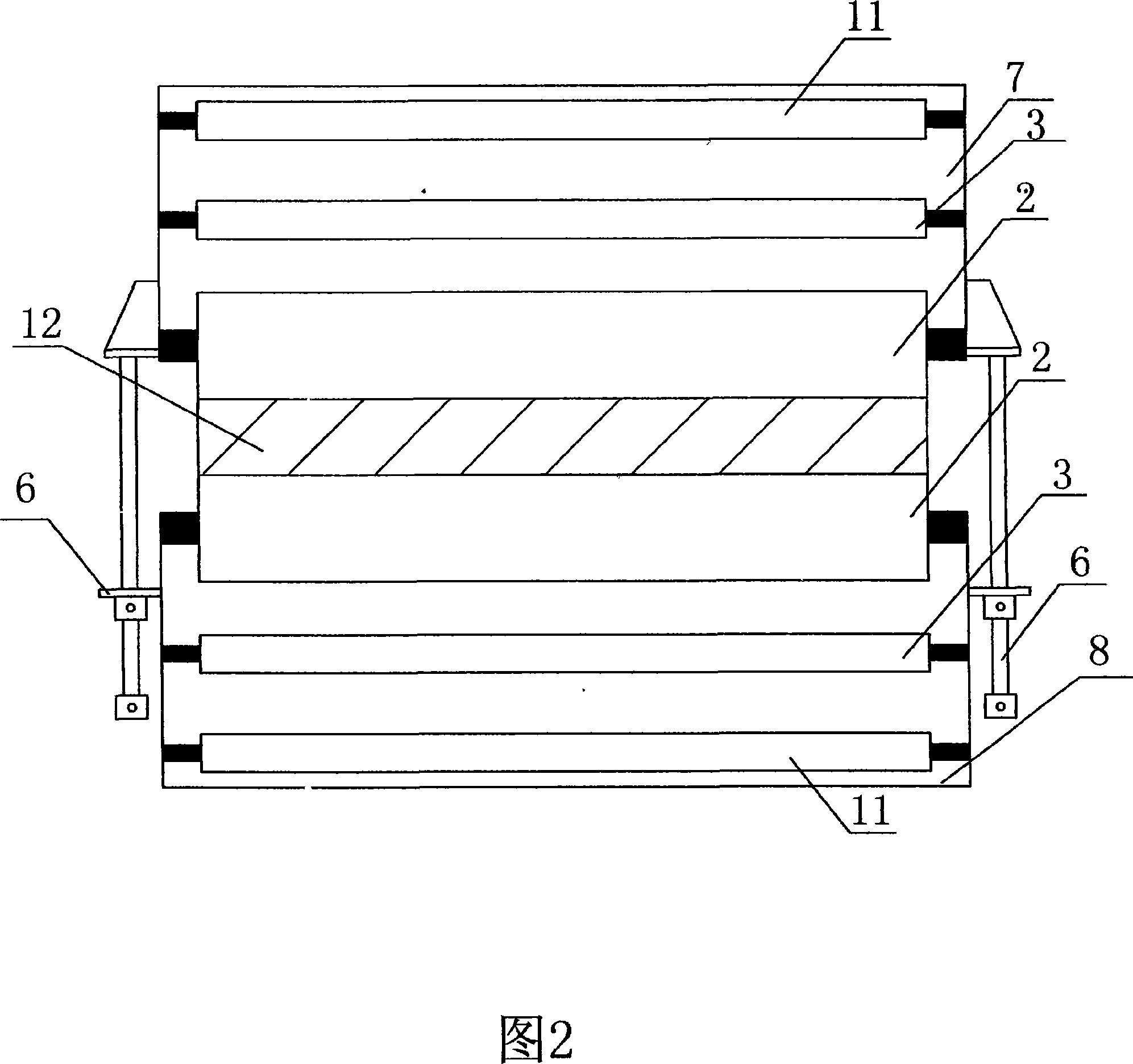

[0024] Entering the forming process: After the carded cotton web is initially formed by laying back and forth according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com