Circulation air path of air cooling type refrigerator

A circulating air duct and air-cooled technology, which is applied in the field of refrigeration equipment, can solve problems such as increased energy consumption, reduced refrigerator efficiency, and particularly obvious pressure loss, and achieves the effects of reducing dead angle, improving refrigeration effect, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

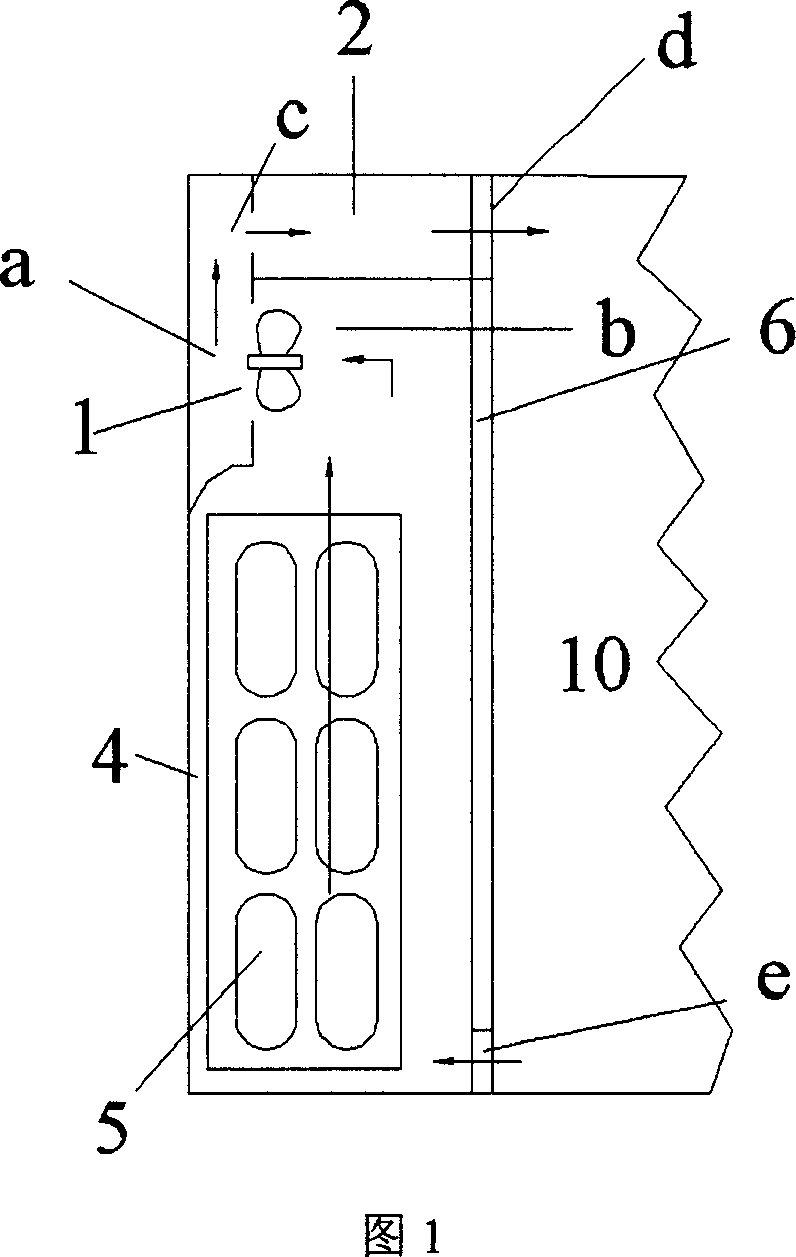

[0028] See Figure 1, where 1 is the axial flow fan, 2 is the air outlet, d is the air outlet, e is the return air outlet, 4 is the cooling chamber, 5 is the evaporator, 6 is the rear side panel of the storage room, and 10 is the storage room. Between objects, the cooling chamber 4 is separated from the storage room 10 by the rear side plate 6 between the storage rooms.

[0029] Wherein, the airflow generated when the axial flow fan 1 rotates flows in the direction of the arrow c, positive pressure is formed in area a, and negative pressure is formed in area b; the rear side panel 6 of the storage room is provided with an air outlet d and a return air outlet e;

[0030] When the axial flow fan 1 is running, a positive pressure is formed in area a, and a negative pressure is formed in area b, thereby generating air flow; the air flow in area a flows to the air outlet d in the direction indicated by arrow c, and then enters the storage room. Heat exchange with refrigerated or fro...

Embodiment 2

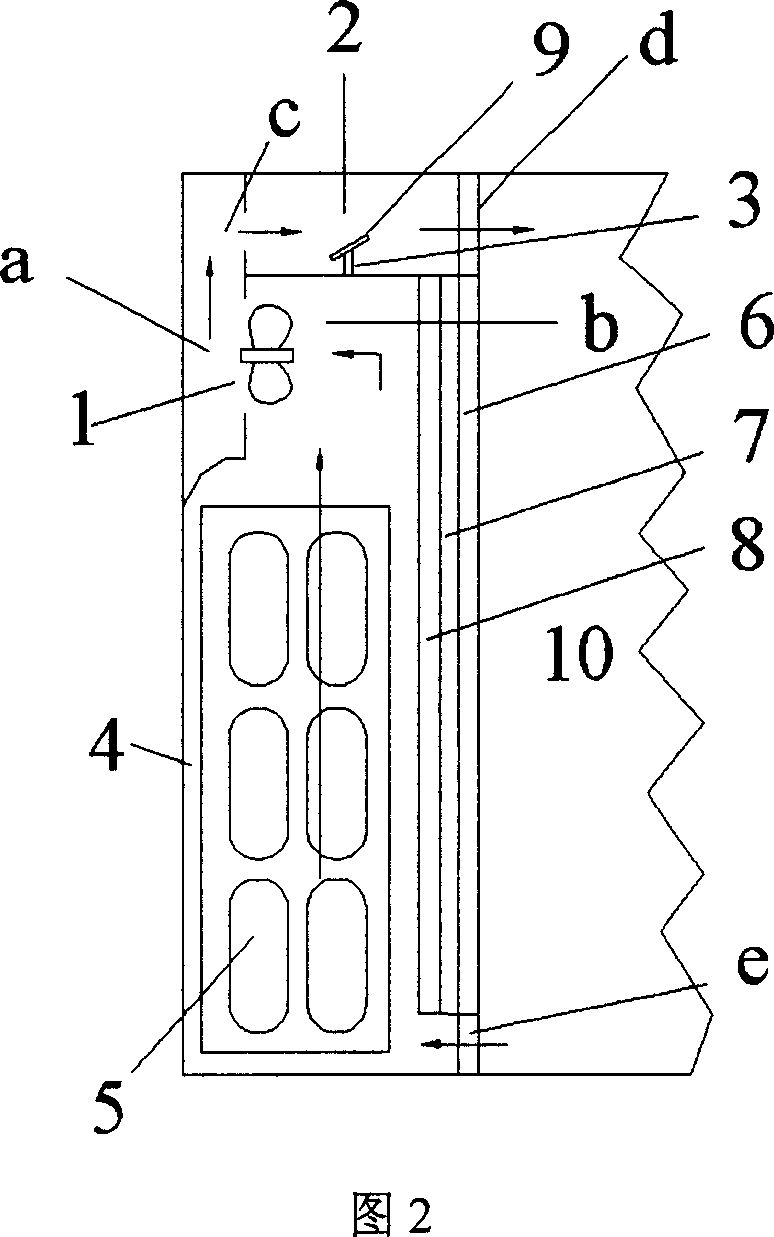

[0032] This embodiment is the result of optimizing it on the basis of Embodiment 1.

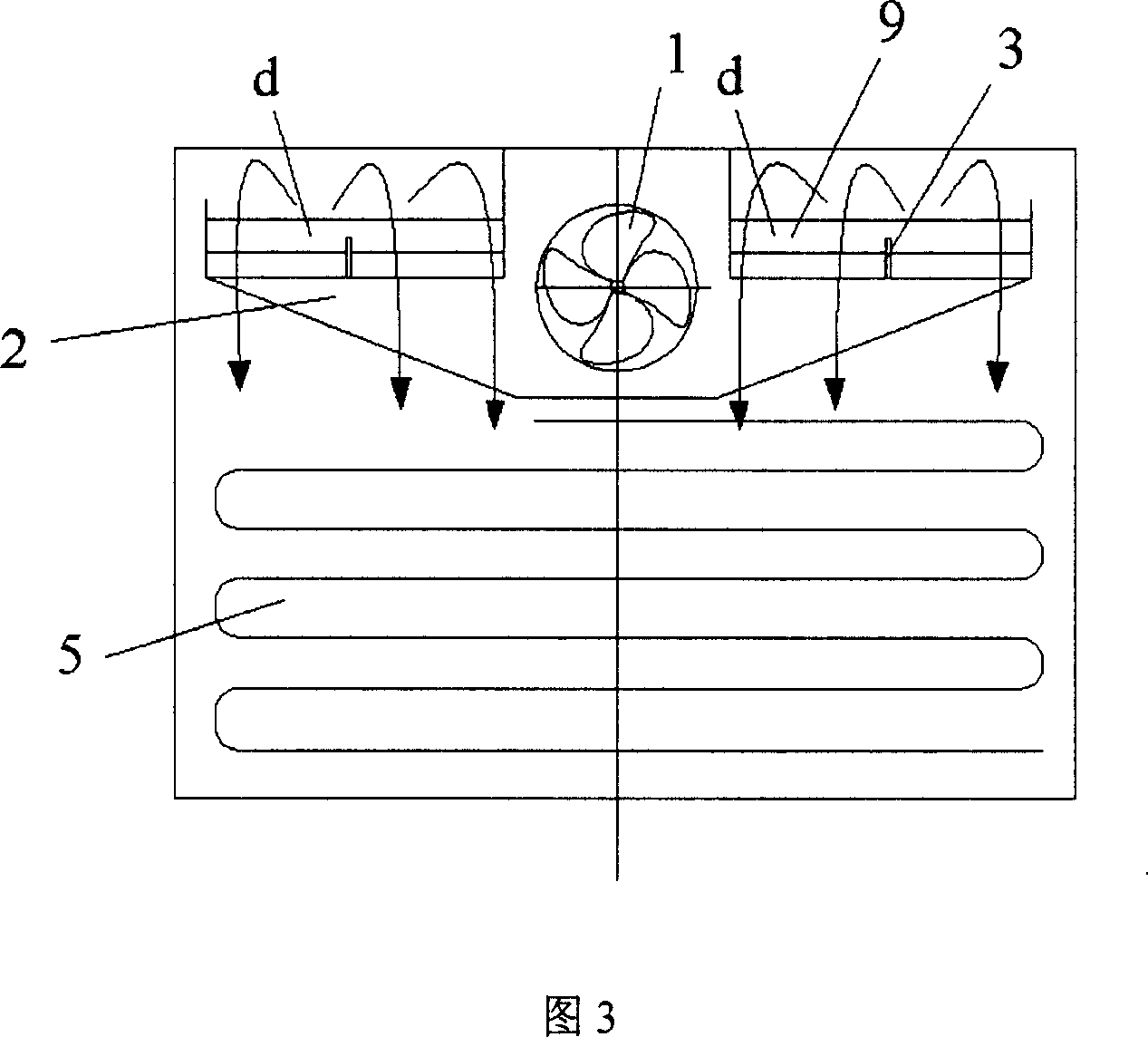

[0033] See Figure 2, where 1 is the axial fan, 2 is the air outlet, 3 is the rib, d is the air outlet, e is the return air outlet, 4 is the cooling room, 5 is the evaporator, and 6 is the rear side of the storage room Plate, 9 is a deflector, 10 is a storage room, and the cooling chamber 4 and the storage room 10 are separated by the rear side plate 6 of the storage room.

[0034] Wherein, the airflow generated when the axial flow fan 1 rotates flows in the direction of the arrow c, positive pressure is formed in area a, and negative pressure is formed in area b; the rear side panel 6 of the storage room is provided with an air outlet d and a return air outlet e;

[0035] Wherein, the insulation layer 7 is a foamed plastic board, and the effect of setting the plastic board is to reduce the heat loss caused by the heat exchange between the cooling chamber 4 and the storage room, avoid unnecess...

Embodiment 3

[0041] This embodiment is the result of adjusting the horizontal inclination angle of the deflector 9 on the basis of the second embodiment, and the rest of the features remain unchanged.

[0042] The horizontal layer of the deflector fixed in the air duct is a sheet structure inclined upward by 30° along the air supply duct opening d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com