Detector for measuring bearing friction torque

A technology for testing devices and friction torque, applied in measuring devices, power measurement, torque measurement, etc., can solve problems that do not involve bearing lubrication conditions and preload conditions, have no angular contact bearing friction torque, and cannot obtain bearing friction conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

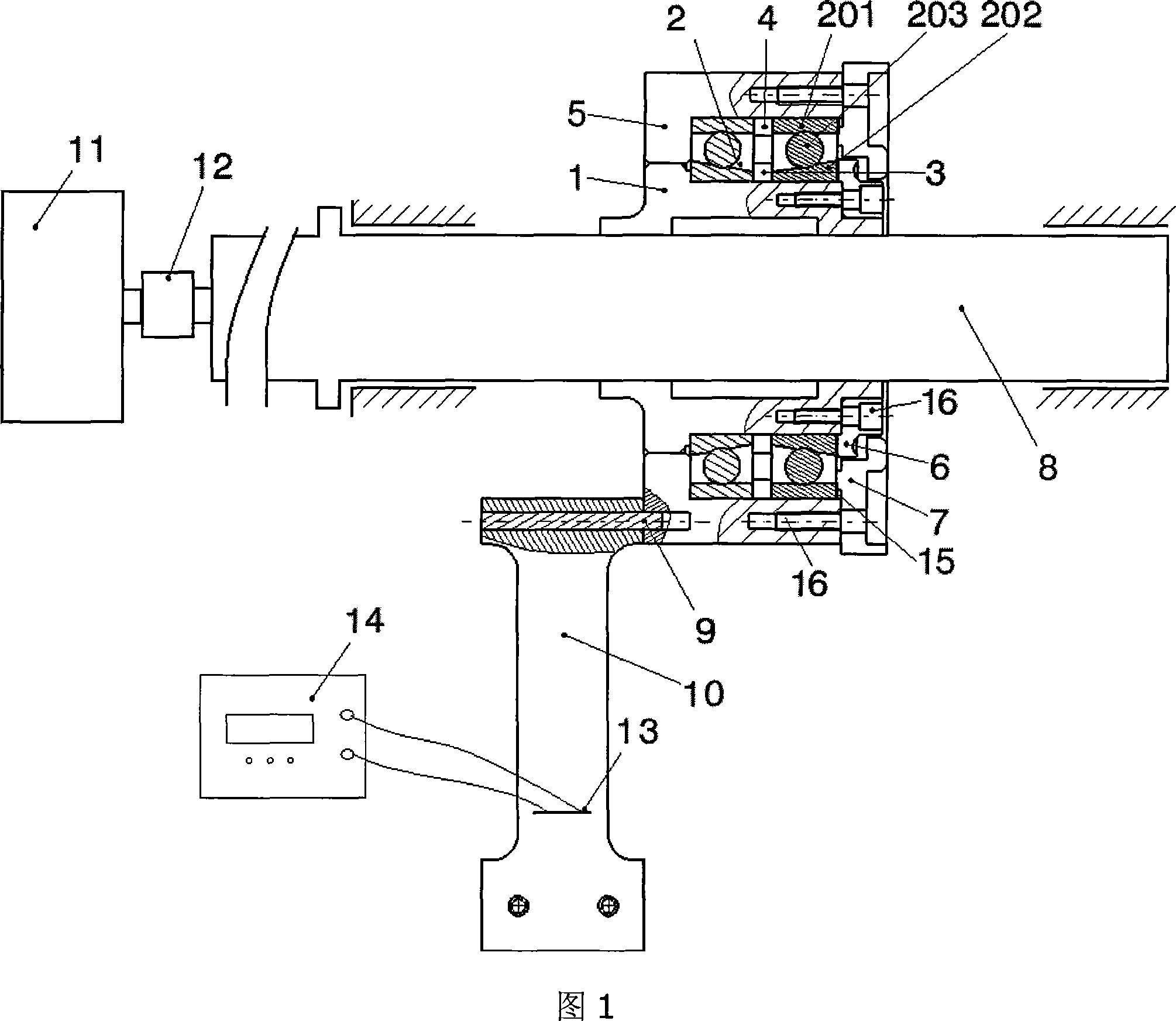

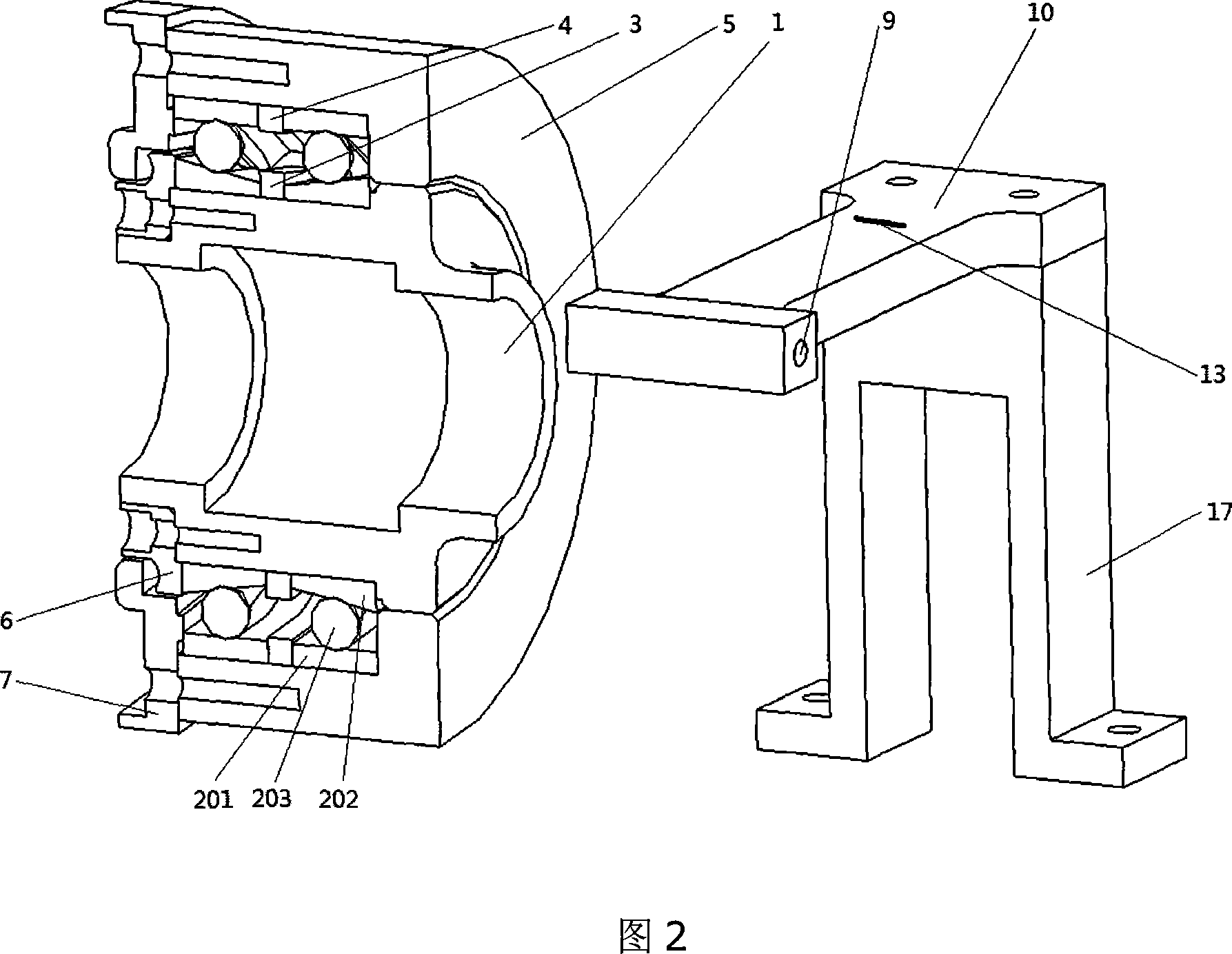

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

[0011] The tested bearing 2 in this embodiment is two angular contact bearings connected in DB mode, and the bearing is composed of an outer ring 201 , an inner ring 202 and a ball 203 embedded in the middle. The inner ring between the two bearings is separated by the inner retaining ring 3, and the outer ring between the two bearings is separated by the outer retaining ring 4.

[0012] During the test, the tested bearing 2 is placed in the groove body formed by the inner shaft 1 and the outer shell 5, and the sealing cover 6 is fixed on the inner shaft 1 with screws 16, and a bearing is placed between the inner shaft 1 and the sealing cover 6. The thickness of the preloaded gasket 15 can be determined according to the magnitude of the preload force applied to the bearing, and make it abut against the inner ring 202 of the tested bearing. The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com