On-site anti-shear strength detector for flexible adhesive material

A technology of shear strength and bonding materials, which is applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problem that the on-site test of the bridge deck waterproof layer cannot accurately reflect the shear performance of the waterproof layer, and the difference in shear force Larger problems, to achieve the effect of enhancing practicability, convenient portability, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

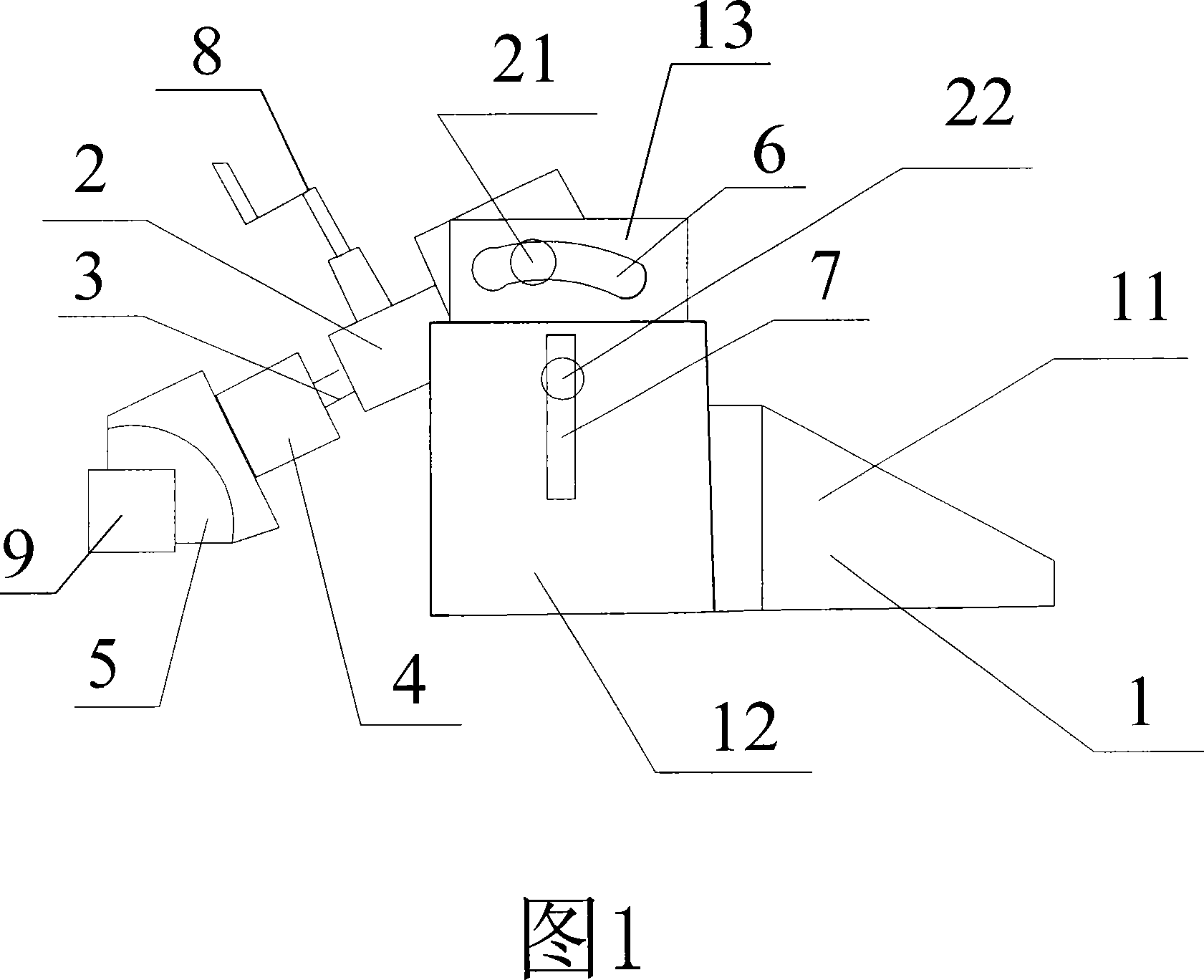

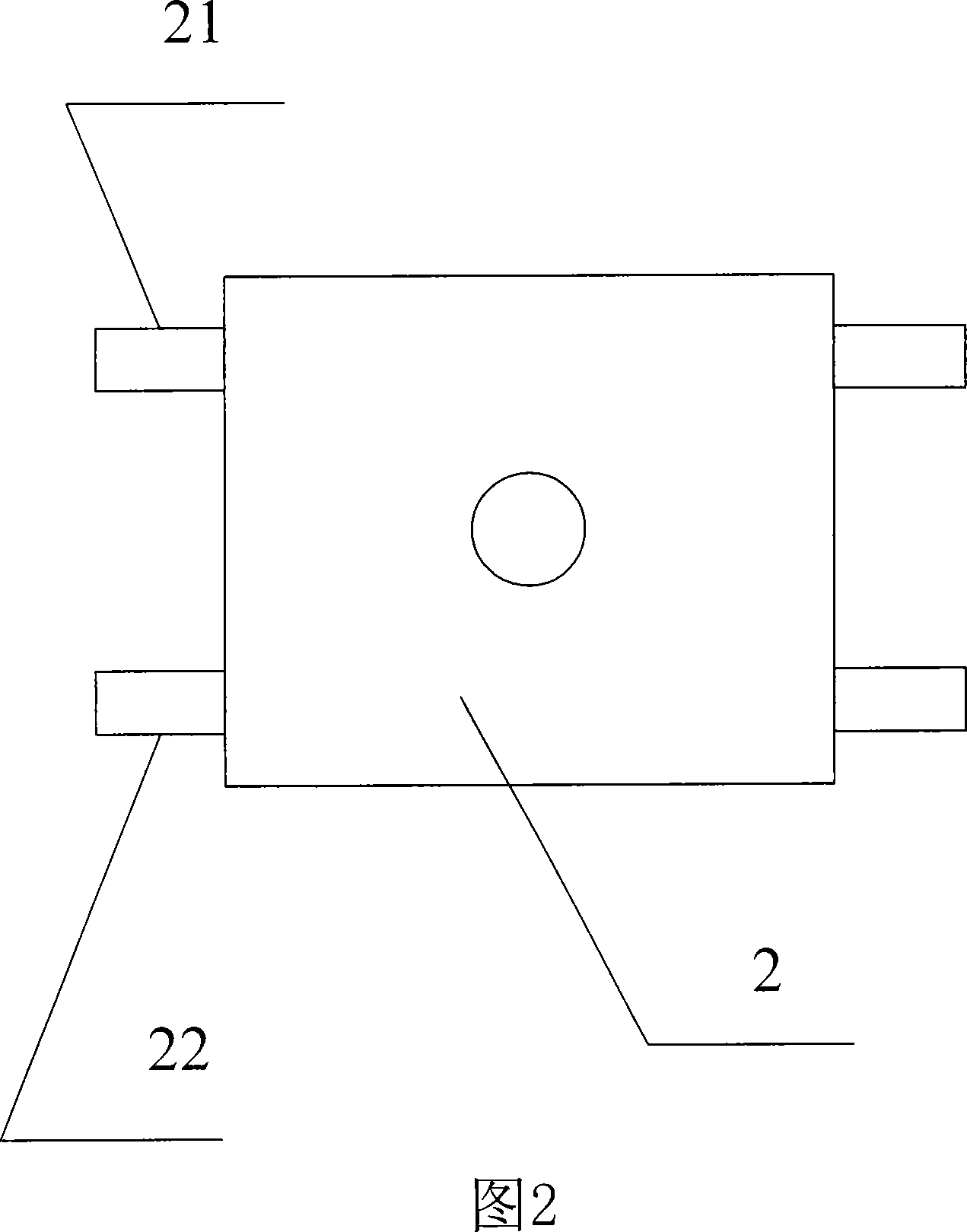

[0012] An on-site shear strength tester for flexible adhesive materials, comprising a transmission 2, a pressure sensor 4, and a pressure head 5, a shaft 3 that can be lifted and lowered is arranged in the transmission 2, the pressure sensor 4 is arranged at the end of the shaft 3, and the pressure head 5 is located at the end of the pressure sensor 3. The field shear strength tester for flexible materials includes a base 1, and the transmission 2 is movably connected to the base 1. In this embodiment, the base 1 includes a bracket 11 and two vertical Arm 12, two upright arms 12 are located at the both sides of machine base 1 and position is opposite, on two upright arms 12, splint 13 is movably connected respectively, and two splints 13 are positioned at the inner side of upright arm 12 respectively, in two The splint 13 is respectively provided with an arc-shaped groove 6, and the two vertical arms 12 are respectively provided with a groove 7, and the groove 7 is located belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com