Plant and internal combustion engine control device

A control system and internal combustion engine technology, applied in general control systems, control/regulation systems, engine control, etc., can solve problems such as the control of the pressure in the intake pipe and the control of the amount of inhaled air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

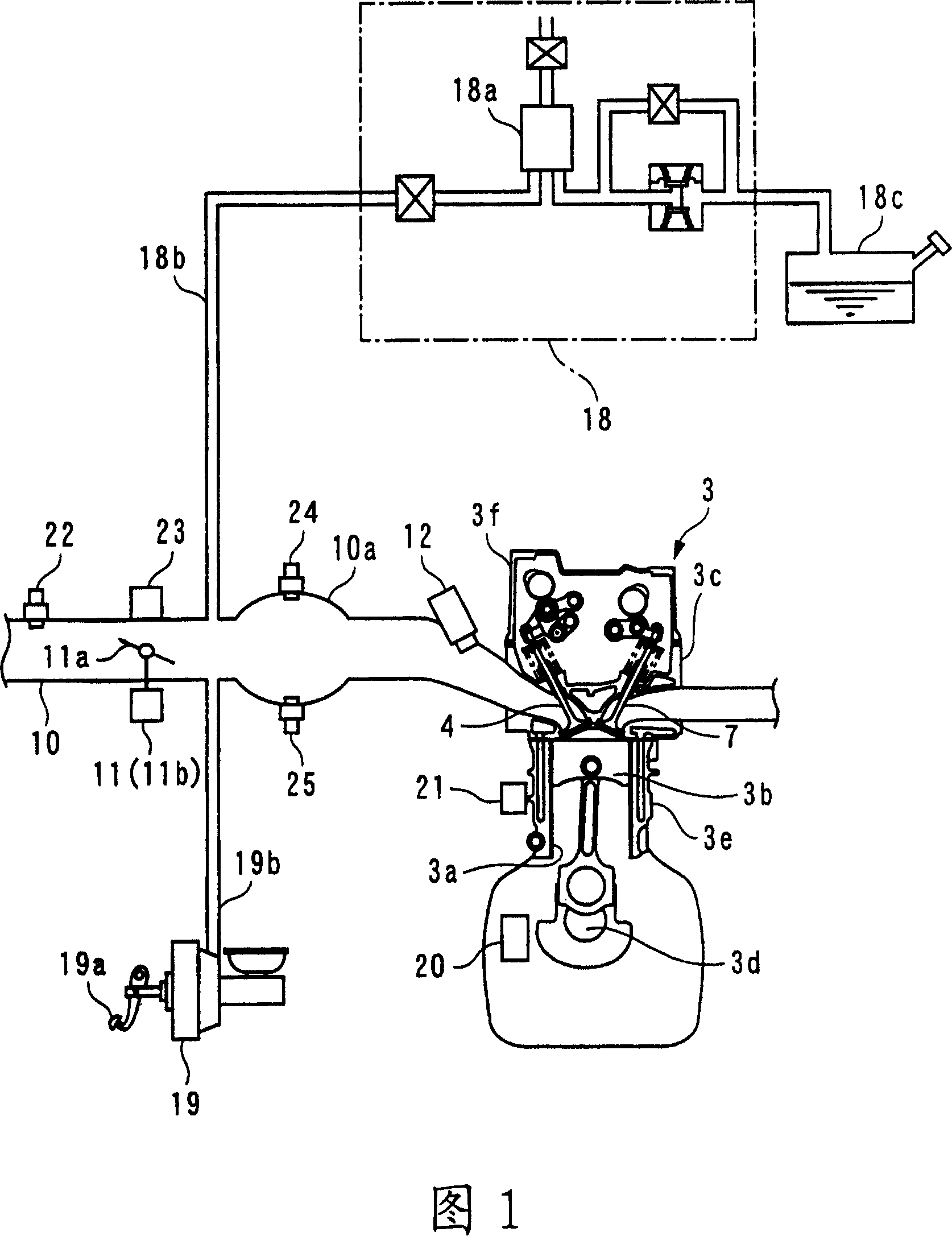

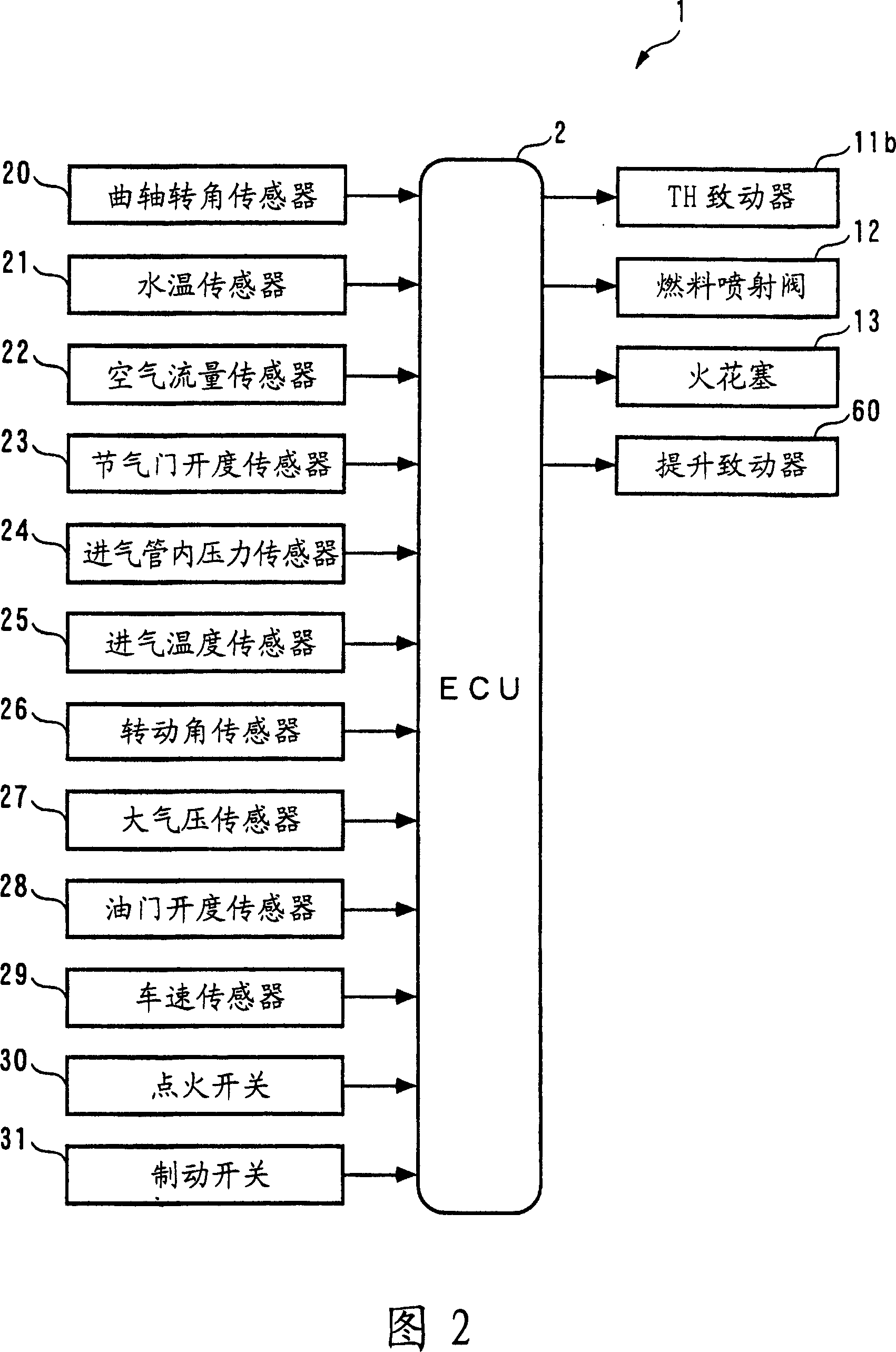

[0100] Hereinafter, a control system according to a first embodiment of the present invention will be described with reference to the drawings. As shown in FIG. 2 , the control system 1 includes an ECU 2 that executes control processing such as variable mechanism control processing in accordance with the operating state of an internal combustion engine (hereinafter referred to as "engine") 3 as will be described later.

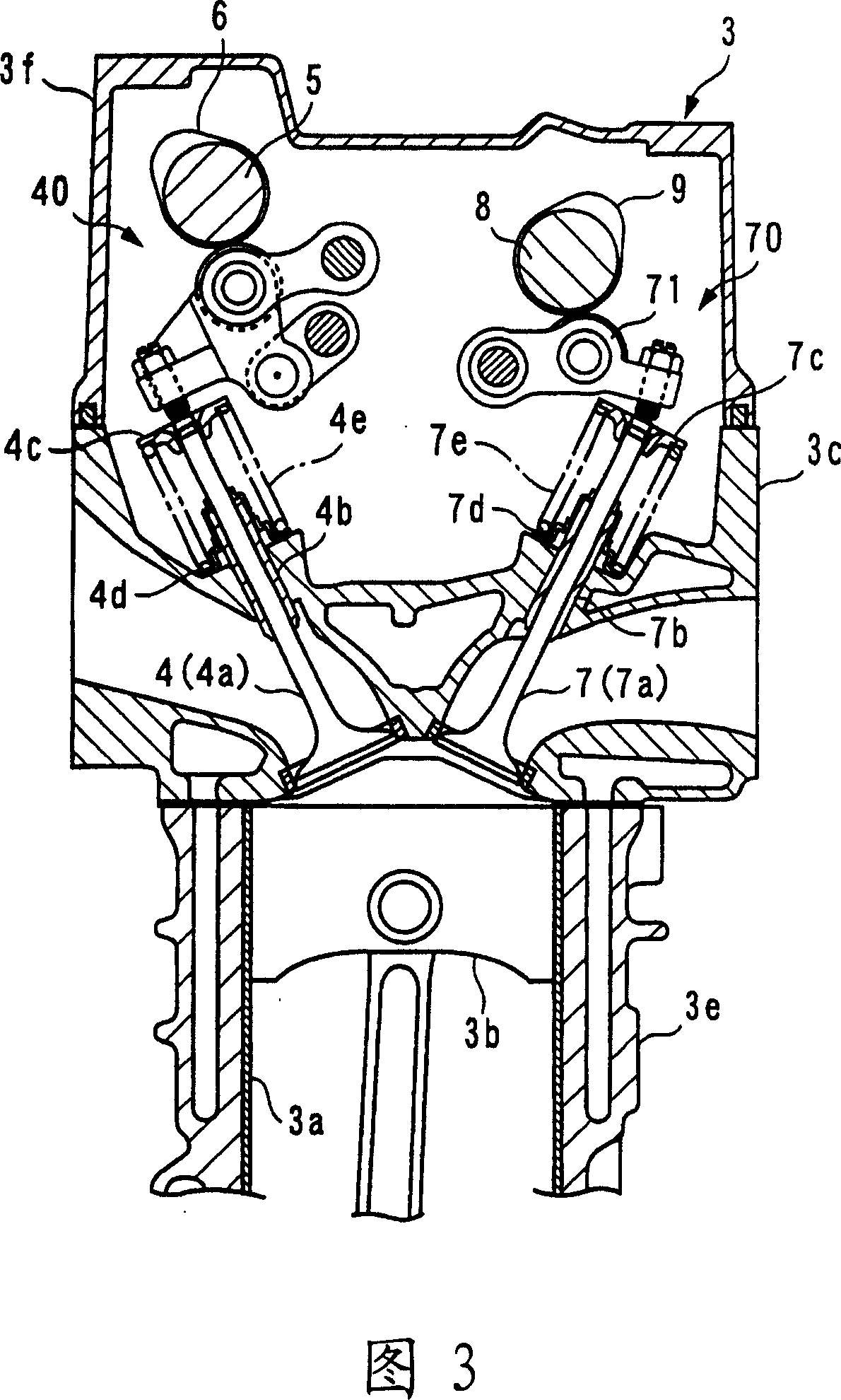

[0101]As shown in FIGS. 1 and 3 , the engine 3 is an inline four-cylinder gasoline engine having four sets of cylinders 3 a and pistons 3 b (only one set is shown), and is mounted on an unillustrated vehicle. The engine 3 has: an intake valve 4 and an exhaust valve 7 which are provided for each cylinder 3a to respectively open and close the intake port and the exhaust port; an intake camshaft 5 and an intake cam 6 for driving the intake valve 4; Variable intake valve transmission mechanism 40 for opening and closing driving intake valve 4; exhaust camshaft 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com