Closed type barrel water drinking machine

A water dispenser, closed technology, applied in packaging, dispensing devices, transportation and packaging, etc., can solve problems such as soda exchange pollution, secondary pollution of buckets, secondary pollution of purified water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

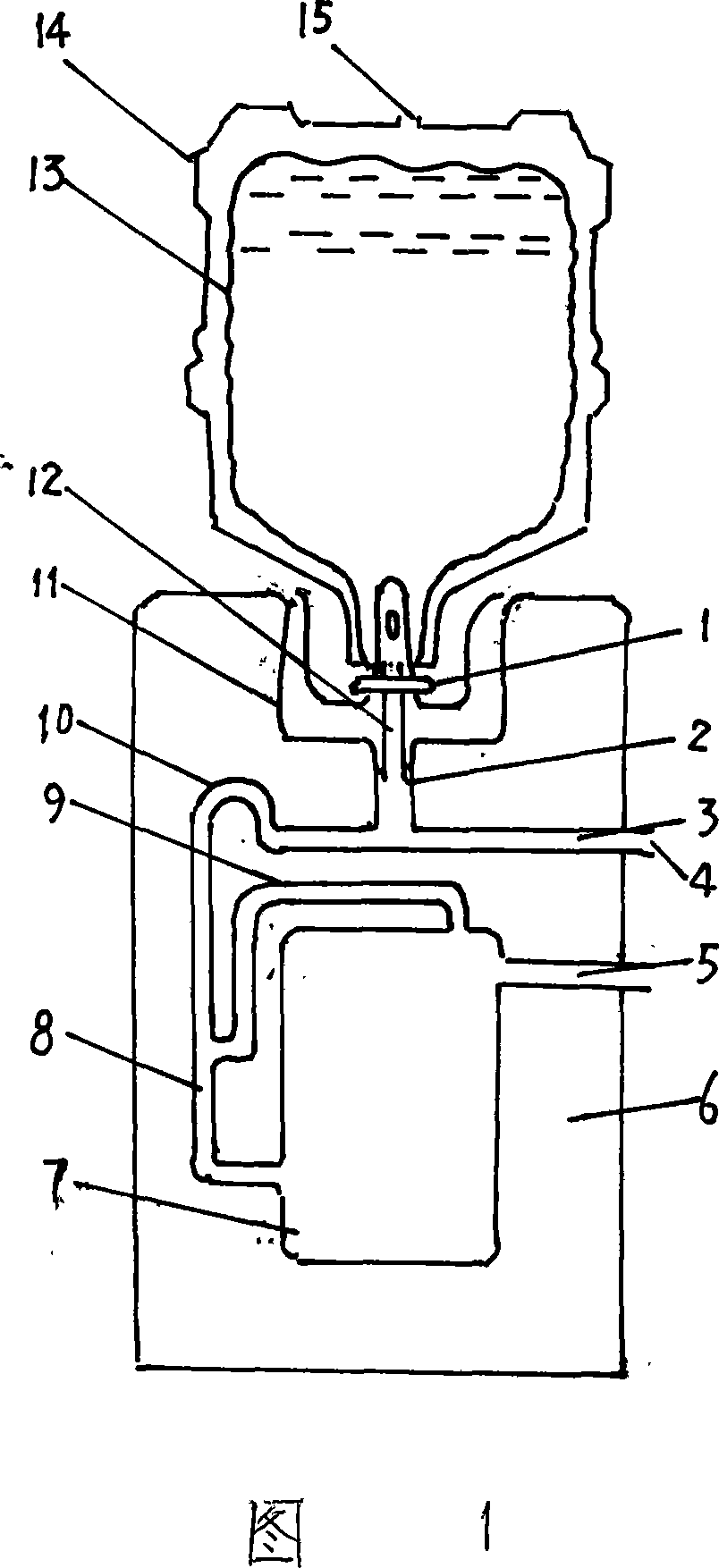

[0017] The closed bucket water dispenser of the present embodiment is shown in Fig. 1 . Body 6 tops retain the water storage basin 11 of existing water dispenser, and the smart head 12 connected with the water outlet of the bucket is equipped with in the center of this water storage basin. In order to ensure the airtight connection, the smart head 12 has a hollow silicon rubber sealing ring 1, so as to ensure that it forms a closed system when it is plugged into the water outlet of the bucket, and effectively prevents water leakage.

[0018] The water outlet at the lower end of the smart head on the top of the water dispenser body 6 is communicated with the horizontal cold water pipe 3 through the water delivery pipe 2. The upper end of the hot water inlet pipe 8 is connected, the lower end of the hot water inlet pipe leads to the bottom of the water heater 7, and the middle part of the hot water inlet pipe 8 leads to the top of the water heater 7 through the hot steam connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com