Repair device for semi-automatic electric rush plating of automobile engine cylinder body plane

A technology of engine block and automobile engine, which is applied in the field of automobiles, can solve problems such as difficulty in mass production, low work efficiency, and no identical or similar literature reports have been found, so as to achieve the effect of ensuring stability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

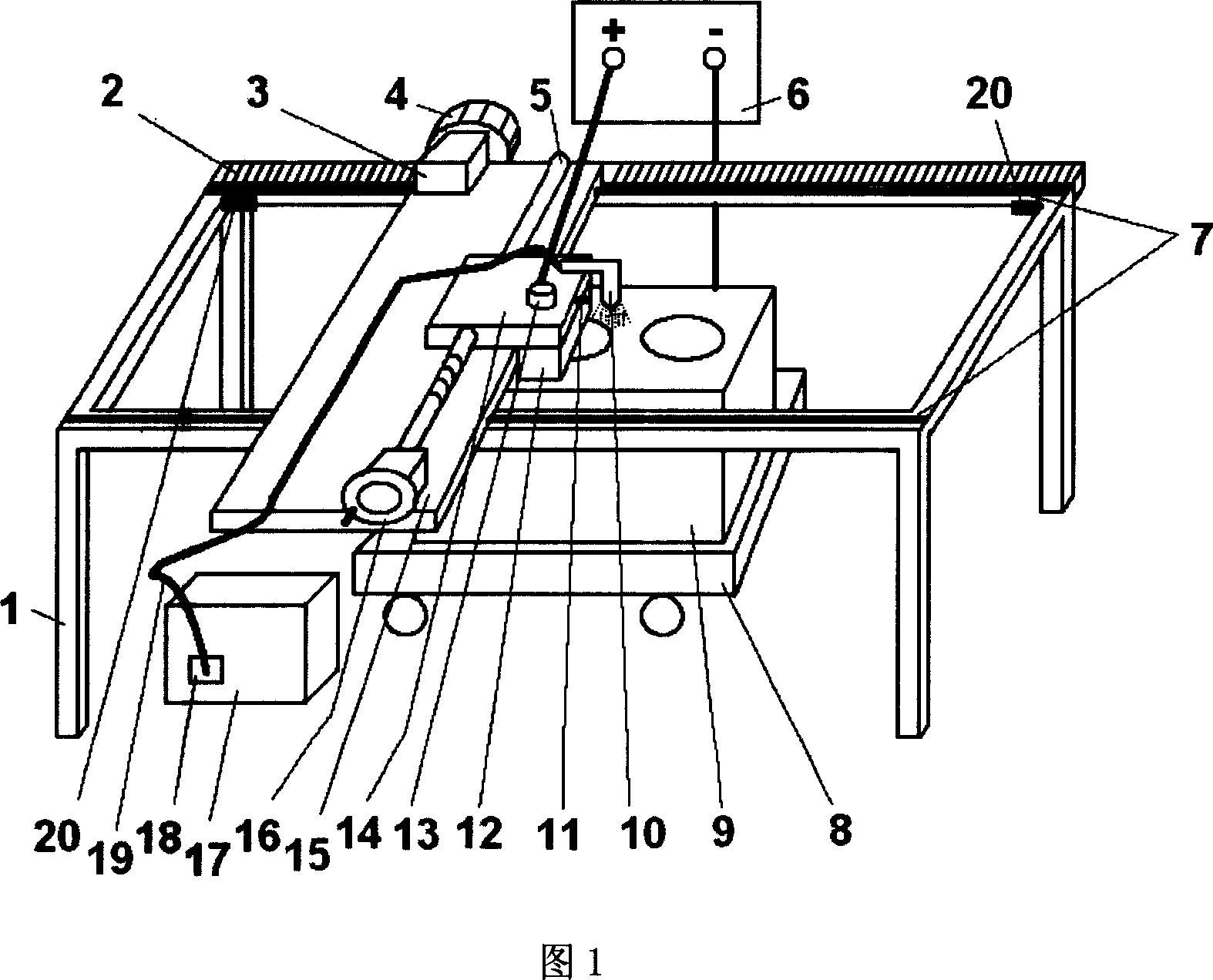

[0011] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0012] As shown in Figure 1, this embodiment includes: frame 1, rack 2, DC speed regulating motor 3, gear 4, feed screw 5, brush plating power supply 6, guide rail 7, lifting platform trolley 8, liquid supply nozzle 10. Plating head adjustment screw 11, anodic plating head 12, plating head adjustment rod 13, small carriage 14, large carriage 15, feed handwheel 16, liquid supply tank 17, liquid pump 18, infusion tube 19, limiter bit switch 20.

[0013] The DC speed regulating motor 3 is fixedly installed on the large carriage 15 and meshes with the rack 2 fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com