Fluid micro-flux measuring method

A measurement method and micro-flow technology, applied in liquid/fluid solid measurement, measurement of flow/mass flow, measurement devices, etc., can solve the problems of precision and complexity, difficult to meet, and low accuracy of micro/nano upgrade micro-flow measurement. The effect of high measurement accuracy, low cost and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

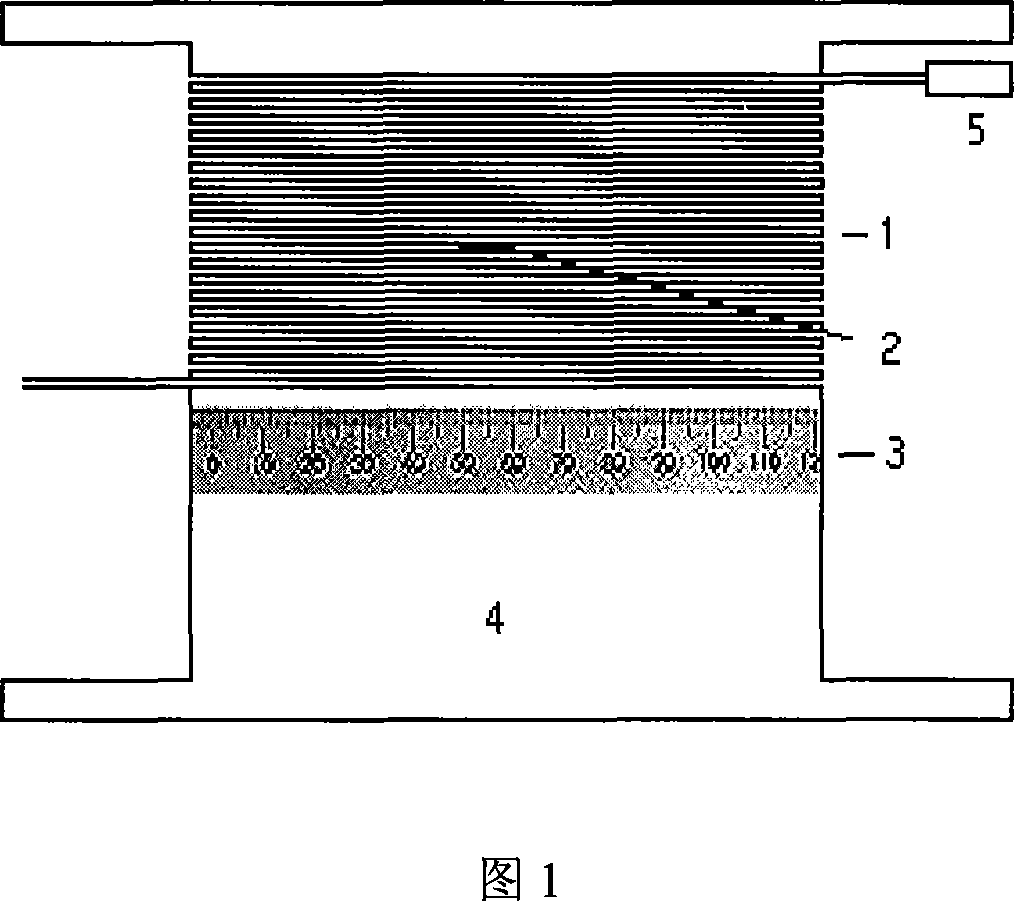

[0017] 1. Select a section of fused silica capillary with an inner diameter of 75 μm, and wash the inner wall with dichloromethane and blow dry with nitrogen.

[0018] 2. The section of capillary tube is regularly wound into a tight spiral shape with a length of 39.70 cm per turn, and a scale is attached to the spiral surface.

[0019] 3. Fill the capillary tube with deionized water, and then inject 1cm Hg column, and then inject deionized water to seal this section of mercury, and ensure that there are no bubbles between the three.

[0020] 4. The flowmeter is connected to the end of the microfluidic liquid chromatography column through a two-way joint, and the distance that the mercury column moves in the microchannel within a certain period of time is measured, combined with the cross-sectional area data of the microchannel, and it can be calculated by the following formula Flow data:

[0021] F=S×L / t (1)

[0022] In the formula, F is the flow rate, S=4.4×10 -9 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com