Device and method for trace to the source for measuring any wave plate retardation

A phase delay and wave measurement technology, which is applied in the field of measuring the phase delay of optical wave plates, can solve problems such as measurement delay, and achieve the effect of compensating system errors and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] 1. Basic principles:

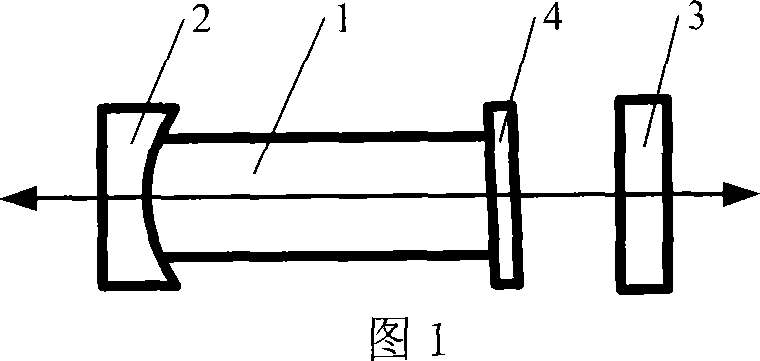

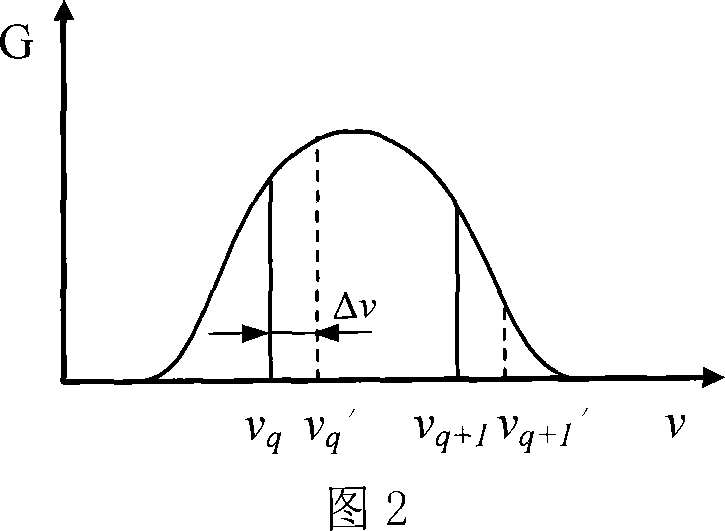

[0037] Fig. 1 is a schematic diagram of a half-cavity He-Ne laser used in a measurement method based on frequency splitting. Among them, the half-cavity laser is composed of a reflector 2, a gain tube 1 and a reflector 3, wherein the two ends of the gain tube 1 are respectively fixed with a reflector 2 and an anti-reflection window 4, and the resonant cavity is formed by the reflectors 2 and 3. Two adjacent longitudinal modes ν of the laser q 、ν q+1 The frequency difference between the longitudinal mode spacing is

[0038] Δ = c 2 L - - - ( 1 )

[0039] Where c is the speed of light, and L is the length of the resonant physical cavity.

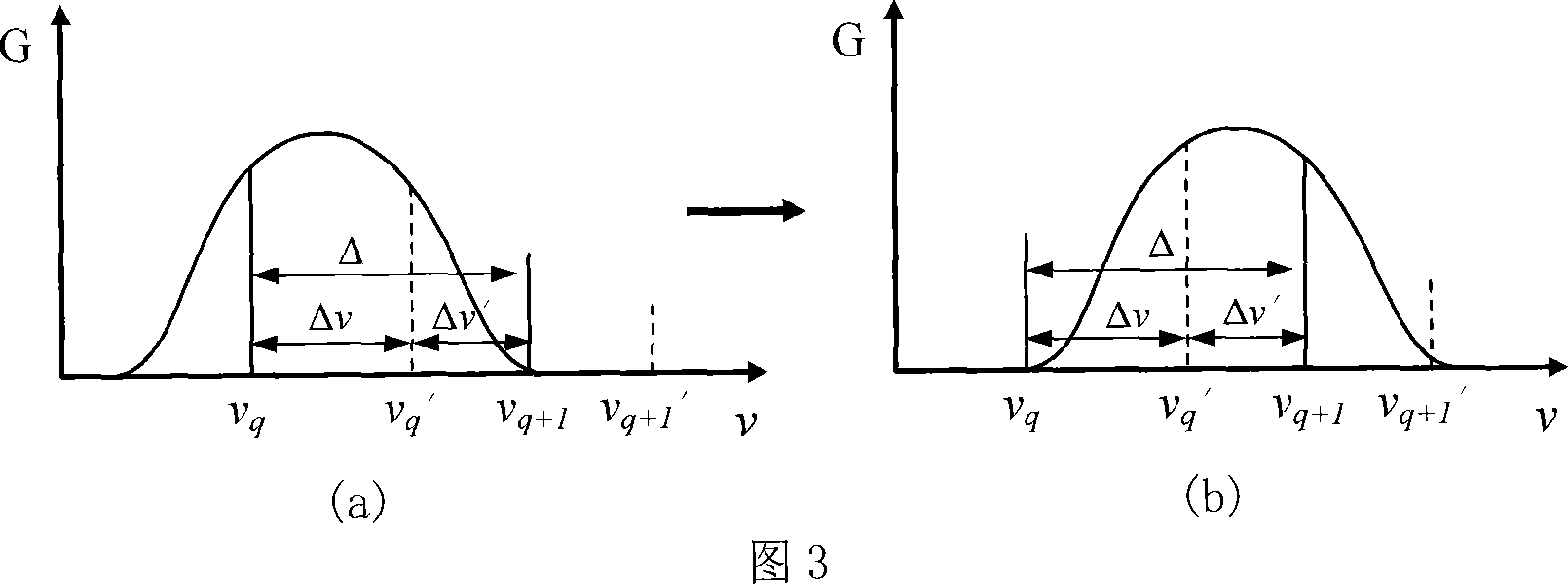

[0040] When a birefringent element is placed in the resonator, the longitudinal mode output by the laser will split, and each original longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com