Fire-extinguishing system capable of continuously preparing carbon dioxide and its method for preparing carbon dioxide

A fire extinguishing system, CO2 technology, applied in fire prevention equipment, fire rescue, etc., can solve problems such as operator injury, sulfuric acid leakage, equipment pressure bearing measures, and insufficient anti-corrosion measures, so as to facilitate equipment anti-corrosion, enhance safety, and gas production big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

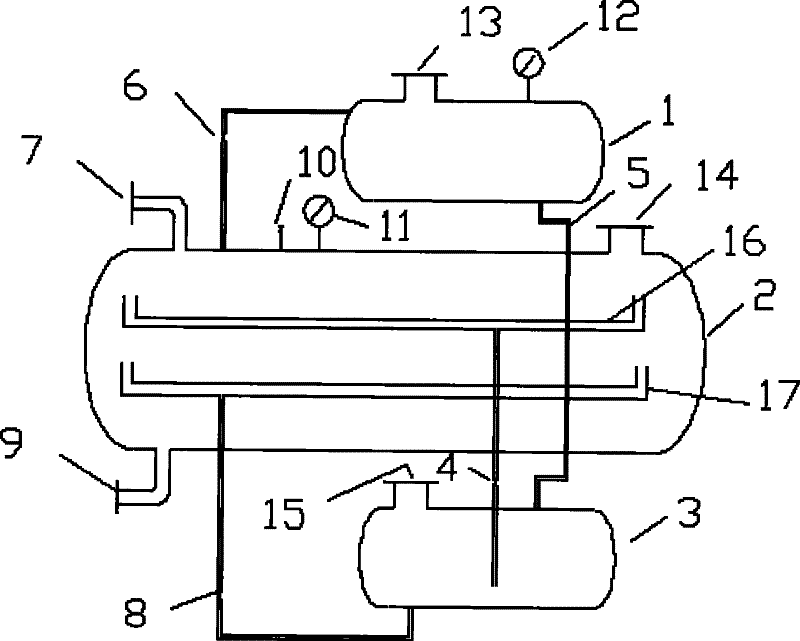

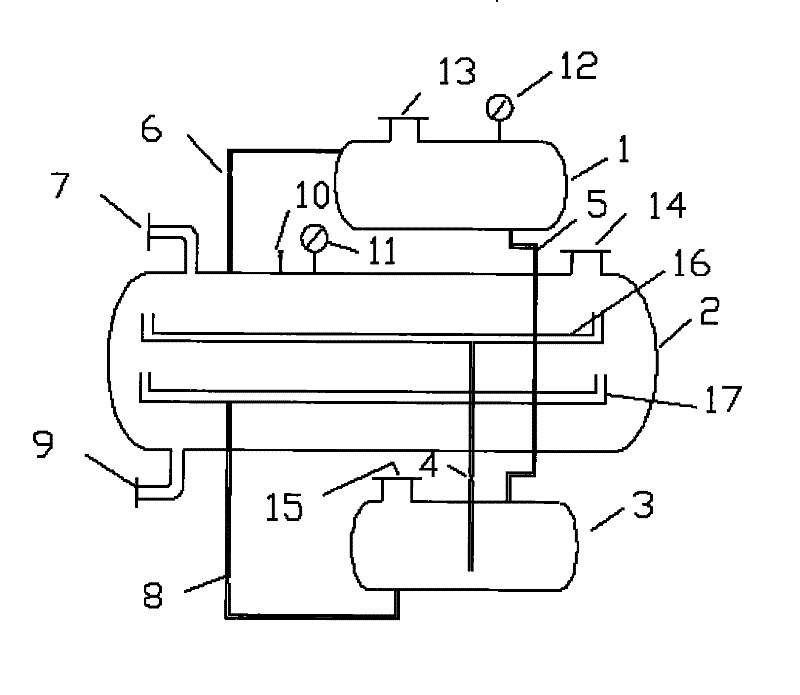

[0033] The CO2 fire extinguishing system provided by the present invention comprises: a carbon dioxide carbon dioxide generator tank 2 and two sulfuric acid raw material tanks 1, 3, the first sulfuric acid raw material tank 1 on the two tops, and the second sulfuric acid raw material tank 3 below are respectively arranged on the carbon dioxide carbon dioxide generator Above and below the tank 2, a gas balance pipe 6 is set between the carbon dioxide carbon dioxide generating tank 2 and the first sulfuric acid raw material tank 1 above, and between the first sulfuric acid raw material tank 1 above and the second sulfuric acid raw material tank 3 below Connecting pipe 5 is set, and a first feed pipe 4 is set in the second sulfuric acid raw material tank 3 below, and its one end is as far as the bottom of the tank, and its other end stretches out from the top of the tank, and stretches in from the bottom of the carbon dioxide generation tank 1. Carbon dioxide generation tank, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com