Railroad car system

A technology for trams and power supply systems, applied in the field of rail train systems, can solve the problems affecting the structure and size of the rail system, operating energy consumption and engineering cost, affecting the widespread popularization of urban rail, and high consumption, etc. The effect of short time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

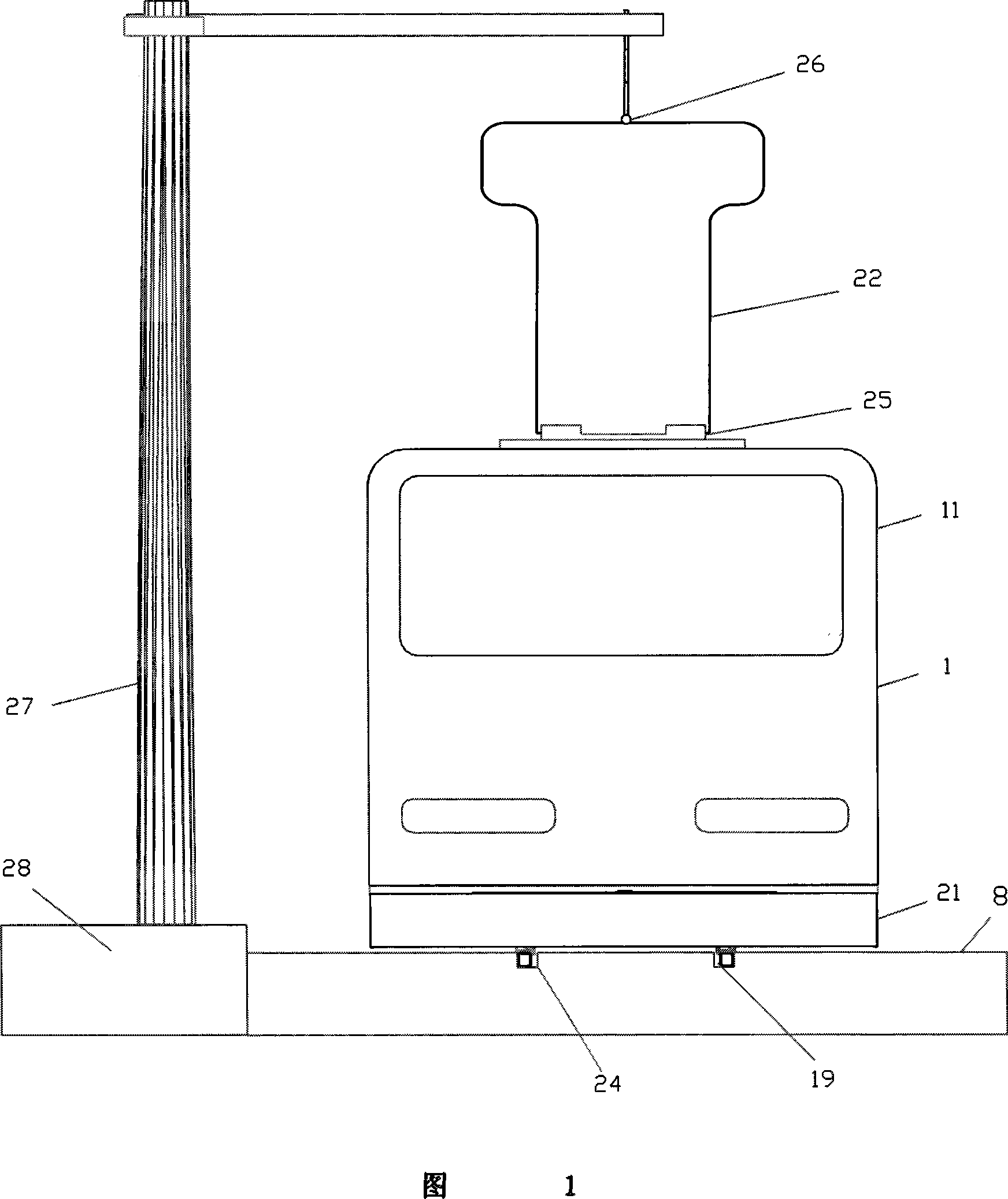

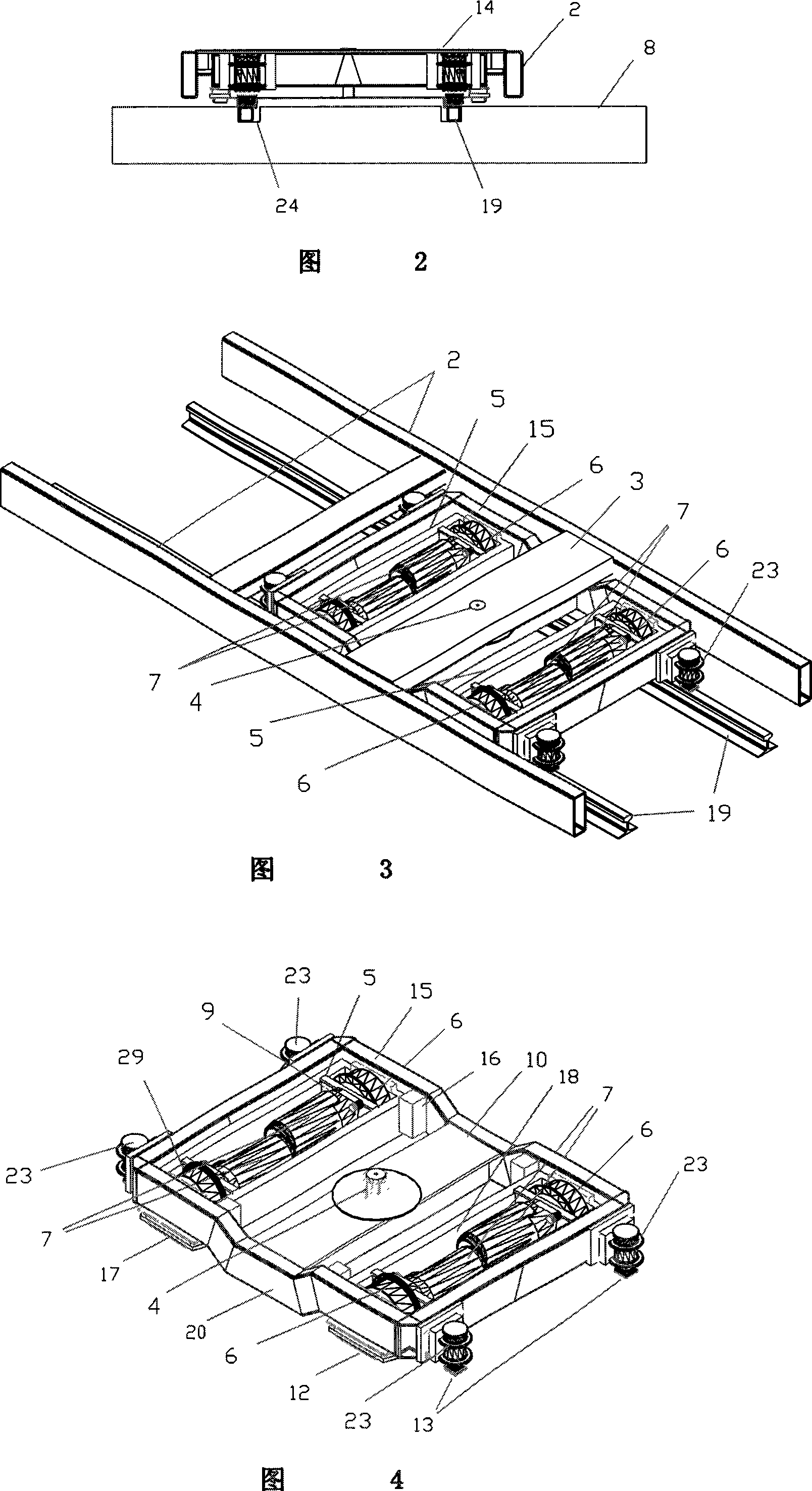

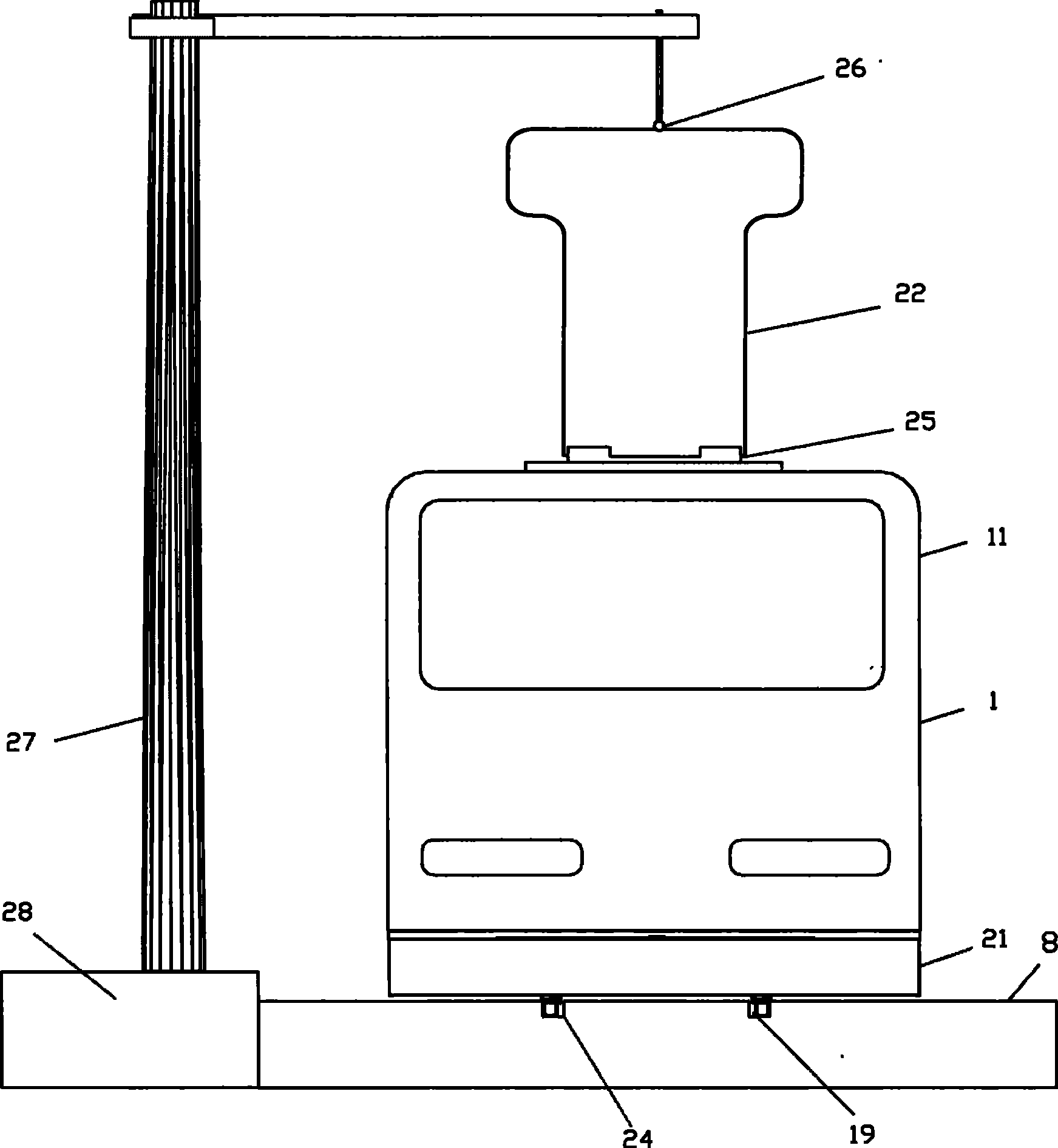

[0036] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] In Figures 1, 2 and 3, the passenger compartment of a light tram with a length of 13.5 meters, an outer width of 2.25 meters, an inner height of 1.95 meters and a compartment wall thickness of 50 mm has 2 dimensions (1.9 × 1.9) meters wide passenger compartment Car door, trapezoidal main vehicle frame 2 are made by the C-section steel of rectangular section size (210 * 75) millimeter, empty weight 6 tons. The sub-frame 15 is 2.5 meters away from the end of the main frame 2. The sub-frame is a rectangular frame made of a rectangular tube with a section (140×60) mm, 1.75 meters long and 1.2 meters wide. The middle section of the sub-frame is 650 mm long on both sides The frame steel pipe 20 is bent downward by 60 mm, and the sub-frame is hinged to the main frame by the vertical shaft mechanism 4 passing through the center of the main frame st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com