Sliding push-the-bit type steering drilling tool

A directional drilling and tool technology, applied in directional drilling and other directions, can solve problems such as high requirements for supporting tools, processes and equipment, high use and maintenance costs, and difficulty in general promotion, achieving broad field application prospects, reliable work, and low cost The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

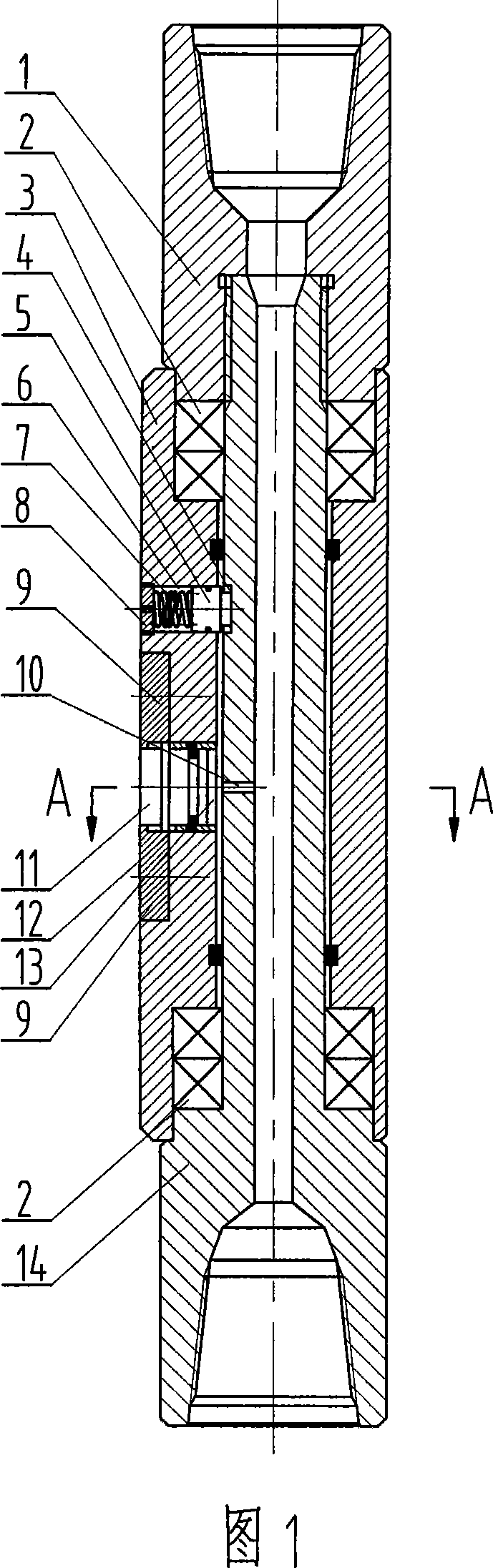

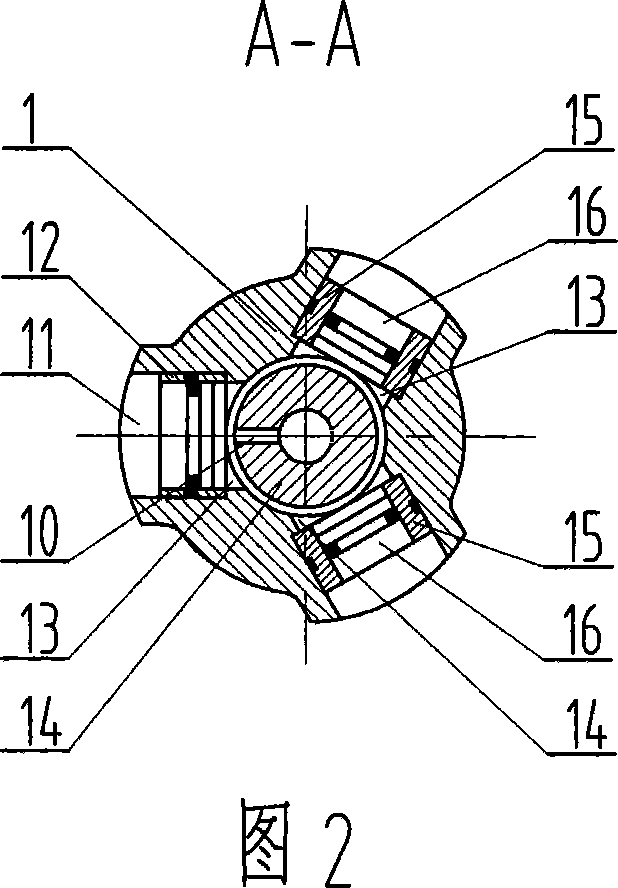

[0014] The present invention will be further described now in conjunction with the accompanying drawings of the description.

[0015] When using the present invention for directional drilling construction, the mandrel [14] is in a stepped shape, a flow channel is processed along the axis, a lock plug groove [4] is processed in the upper part, and a pressure guide hole [10] is processed in the middle part, and the bearing [ 2] Fit the hollow cylindrical sliding sleeve [3] and the mandrel [14] sequentially, then connect the conversion joint [1] to the upper end of the mandrel [14], and the middle part of the sliding sleeve [3] body is evenly processed around its axis. Piston cylinder [13], the diameter of guide piston [11] is greater than the diameter of stable piston [16], the internal diameter of guide piston cylinder liner [12] is greater than the internal diameter of stable piston cylinder liner [15], guide piston [11] and guide After the piston liner [12], the stabilizing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com