Micro-optical fiber ring dye laser with evanescent wave coupling gain

A dye laser and micro-fiber technology, applied in the field of micro-optical components, can solve the problems of difficult application, unstable structure, unfavorable optical integration, etc., and achieve the effect of simple preparation and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

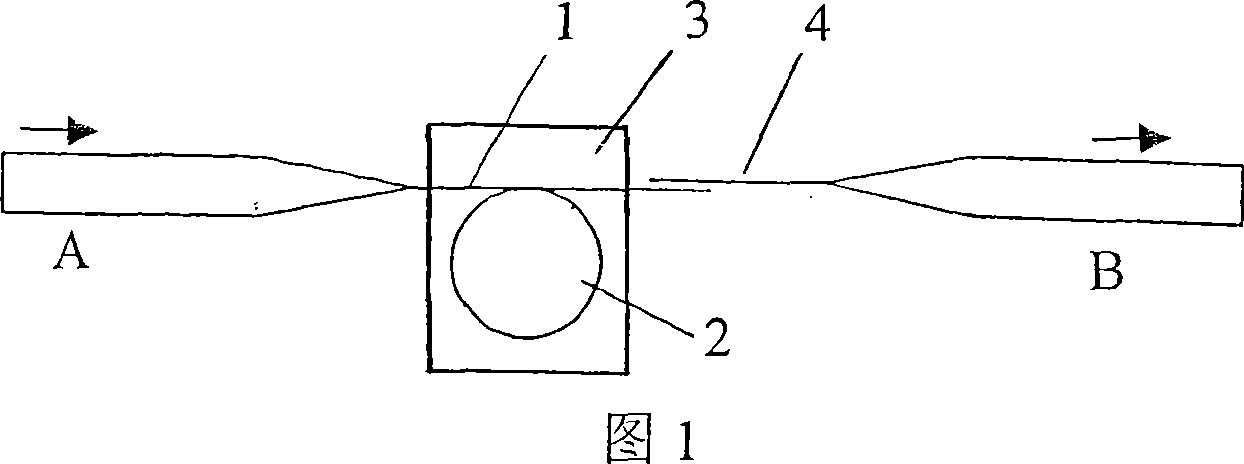

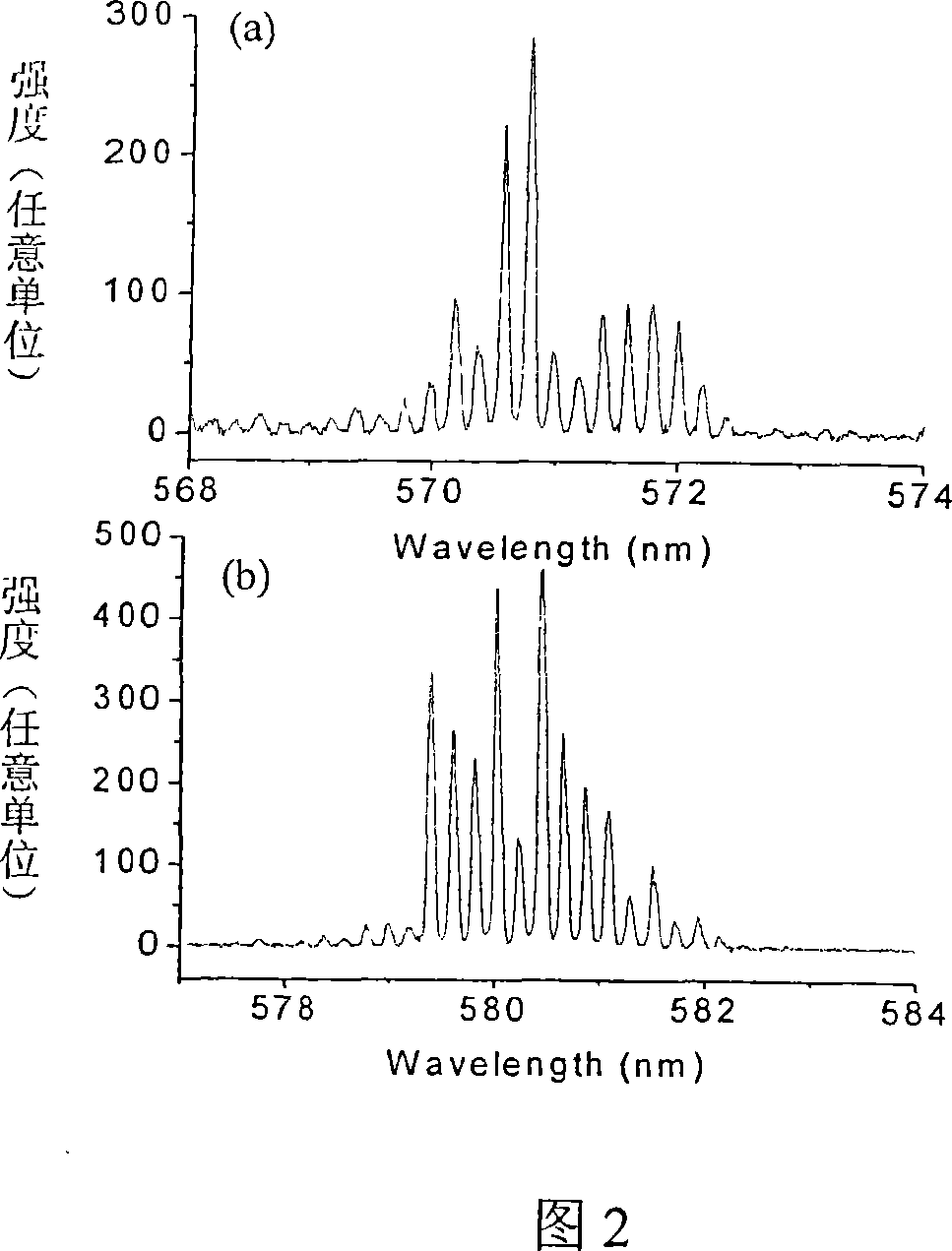

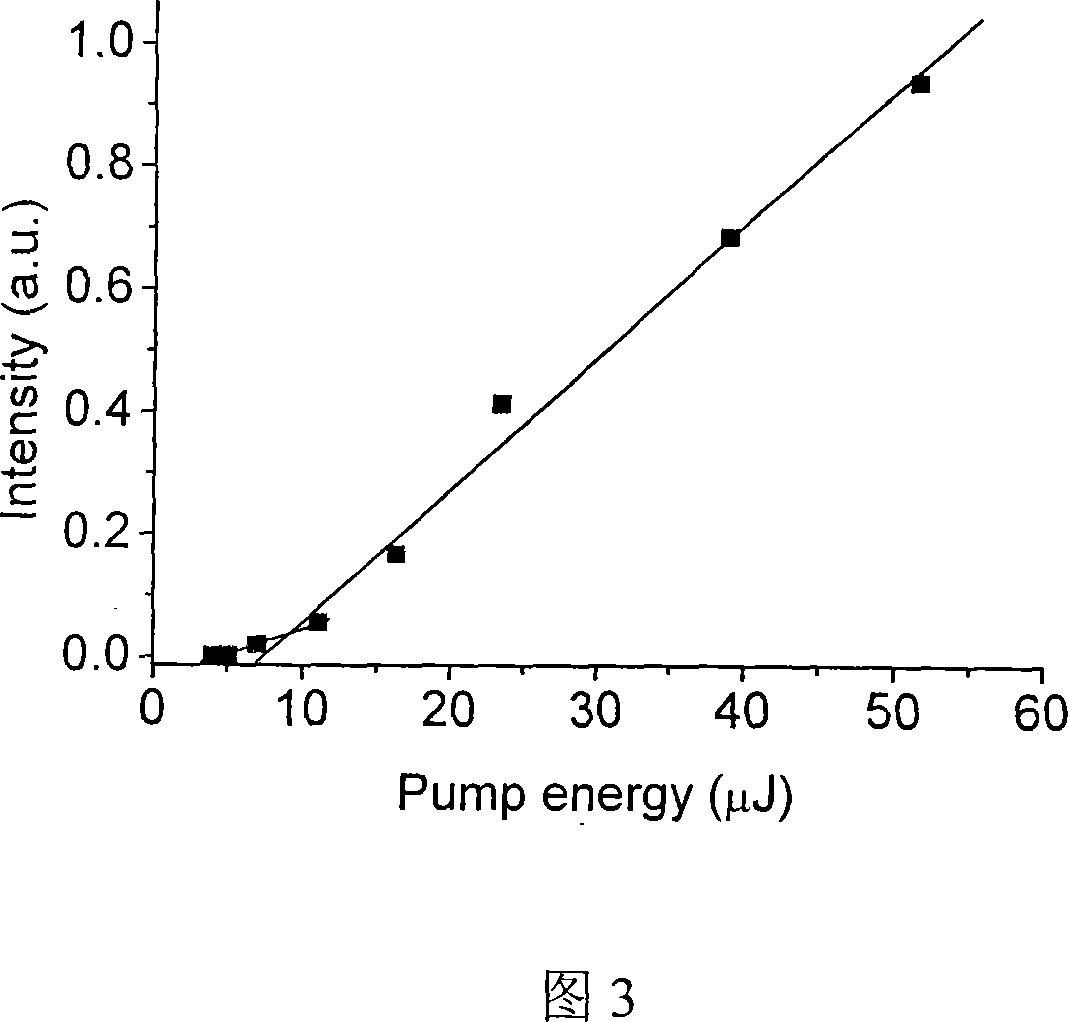

[0011] As shown in Figure 1, the present invention is prepared into ring junction resonator 2 with the first microfiber 1, and one end of ring junction resonator 2 is connected with single-mode optical fiber, and the other end of ring junction resonator 2 is connected with second microfiber 4 coupling, the ring junction resonator 2 is immersed in the solution 3 doped with the gain medium, and the gain medium is excited by the evanescent wave distributed on the surface of the micro-fiber to generate laser light.

[0012] The diameter of the micro-fiber is 0.5-5 μm. The ring junction laser has a diameter of 50 μm to 10 mm. The ring junction resonator is a ring single junction resonator. The gain medium mixed with rhodamine 6G dye solution, rhodamine B dye solution or quantum dot solution.

[0013] The preparation process of the present invention is as follows:

[0014] (1) Firstly, a single-mode optical fiber is drawn by a high-temperature stretching method to prepare a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com