Comb-like membrane-bioreactor having free end

A technology of bioreactor and bioreaction tank, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the complex structure of membrane modules, low water permeability, inconvenient installation, disassembly and washing, etc. problems, to achieve the effect of convenient cleaning of membrane filaments, strong anti-pollution ability, and not easy to accumulate sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

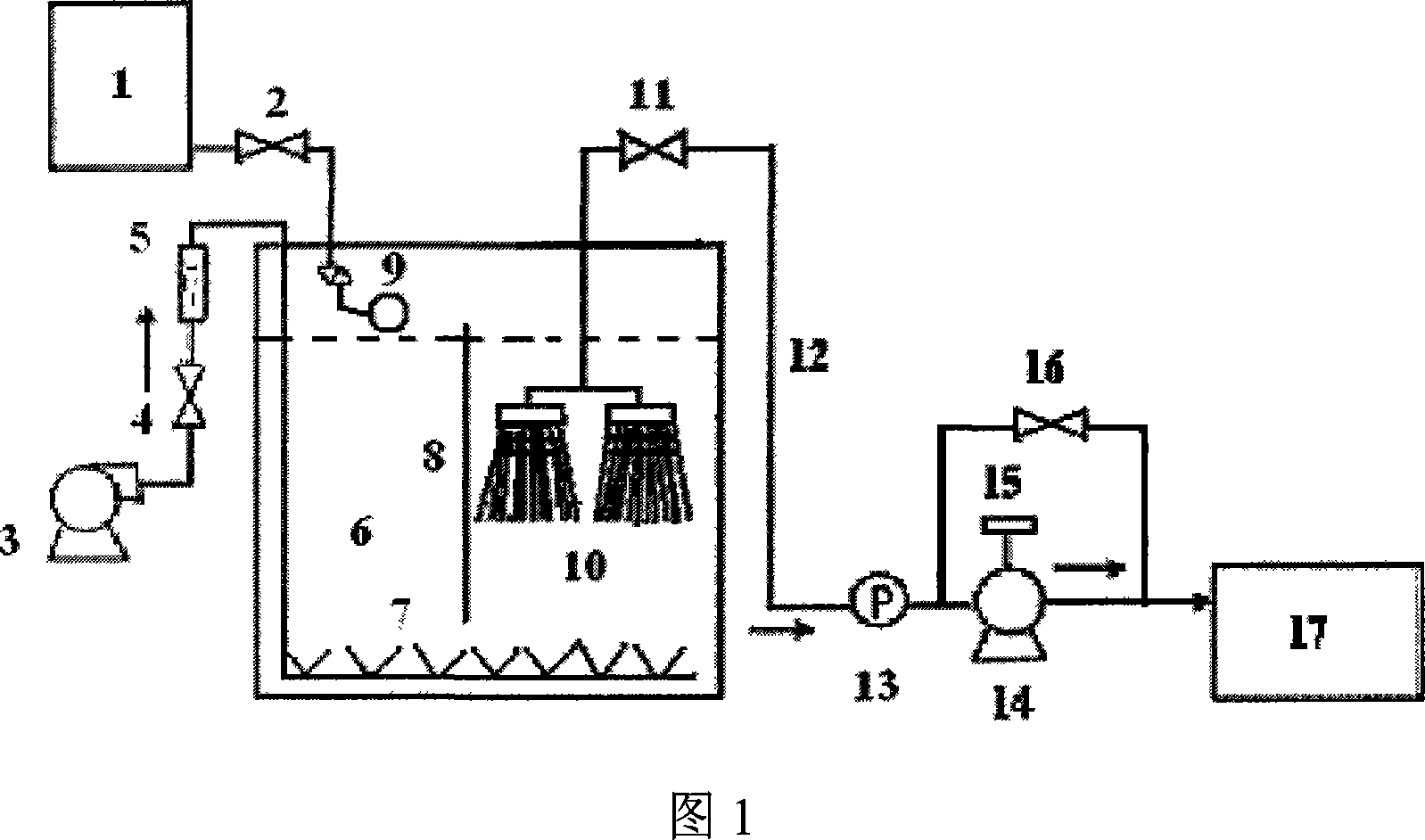

[0013] As shown in Figure 1, the comb-like membrane-bioreactor with free end has membrane-bioreactor tank 6, is provided with baffle plate 8 in the membrane-bioreactor tank, and baffle plate divides membrane-bioreactor tank into sludge mixed oxidation zone and There are two parts of the outlet area of the membrane module. The sludge mixed oxidation area is connected to the bottom of the membrane module outlet area. The upper part of the sludge mixed oxidation area is equipped with a liquid level controller 9, and the bottom of the membrane-biological reaction tank is equipped with an aerator head 7. The membrane module outlet water A comb-shaped membrane module 10 with a free end is provided in the area, and the comb-shaped membrane module with a free end is connected with the third valve 11, the water outlet pipe 12, the vacuum pressure gauge 13, the water outlet suction pump 14, and the clean water tank 17. The pump is connected to the time relay 15, the siphon pipeline 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com