Node component used for connecting steel tube concrete column with building roof beam

A technology for concrete-filled steel tubular columns and nodes, which is applied in building structures, buildings, etc., can solve the problems of excessively large cross-section of steel ring plates, difficult construction, and difficult to control the center of gravity of hoisting, so as to improve shear resistance, reduce dome extension effect, Enhance the effect of beam-column connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

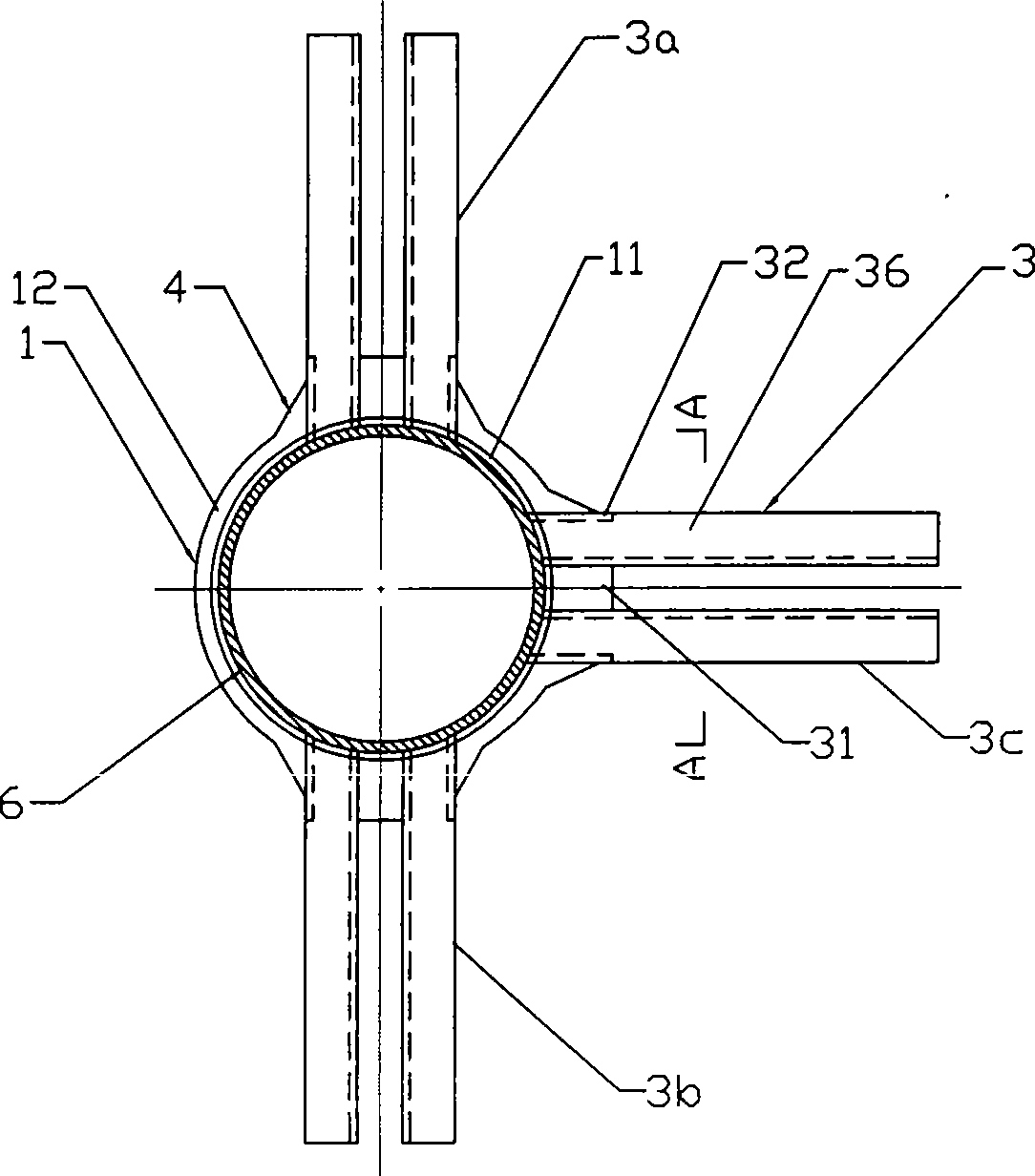

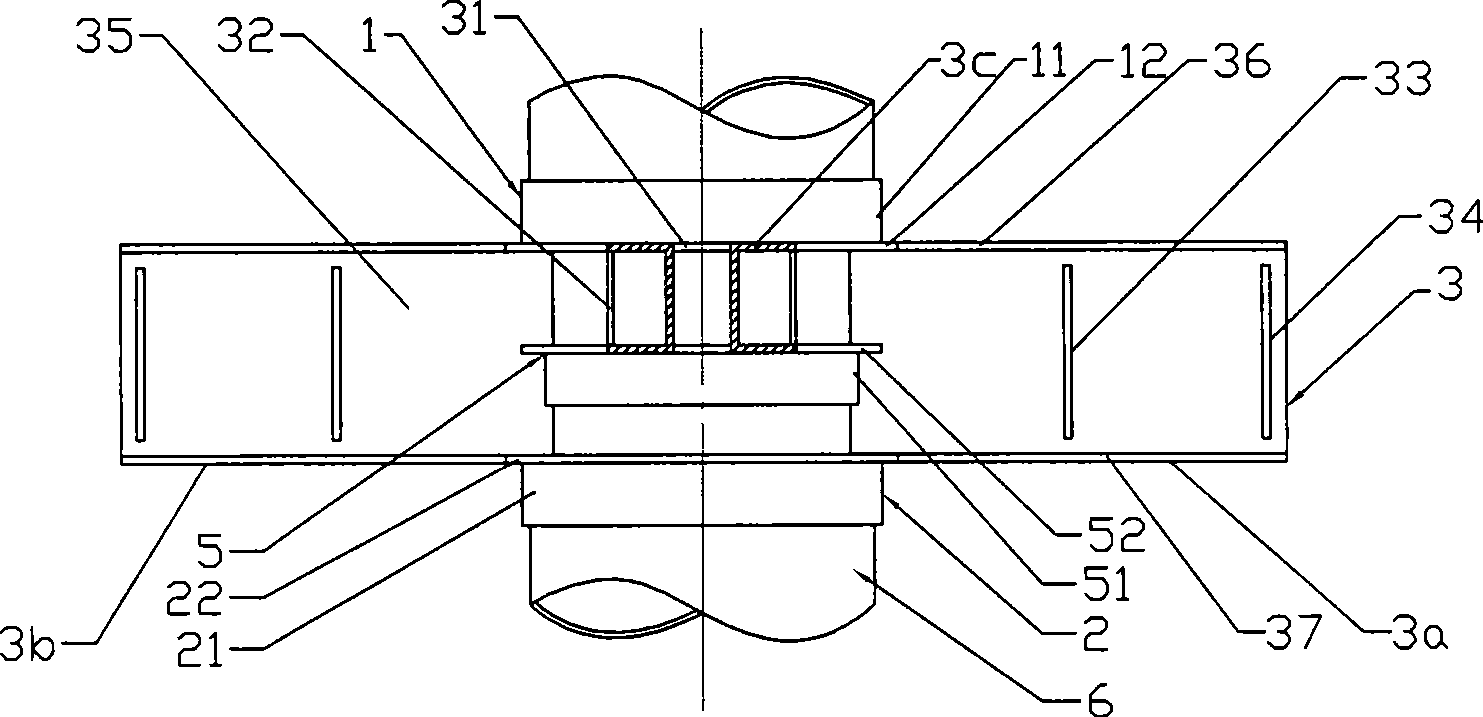

[0039] A specific implementation of the node component used to connect the steel pipe concrete column and the floor beam according to the present invention is as follows: figure 1 ,figure 2, Figure 4 As shown, the node member includes a steel pipe 6 and three steel corbels 3a, 3b, 3c arranged in a "T" shape at intervals of 90° along the horizontal plane, and the three steel corbels 3a, 3b, 3c have different heights in the vertical direction layout.

[0040]The upper flange 36 and the lower flange 37 at the root of the three steel corbels 3a, 3b, 3c are provided with horizontal stiffeners 31, and between the upper flange 36 and the lower flange 37 there is a The vertical stiffening plate 32, the above-mentioned horizontal stiffening plate 31, the vertical stiffening plate 32 and the upper flange 36 and the lower flange 37 at the root of the steel corbels 3a, 3b, 3c jointly form a box-type structure. The side walls of the webs 35 of the steel corbels 3a, 3b, 3c are provided w...

Embodiment 2

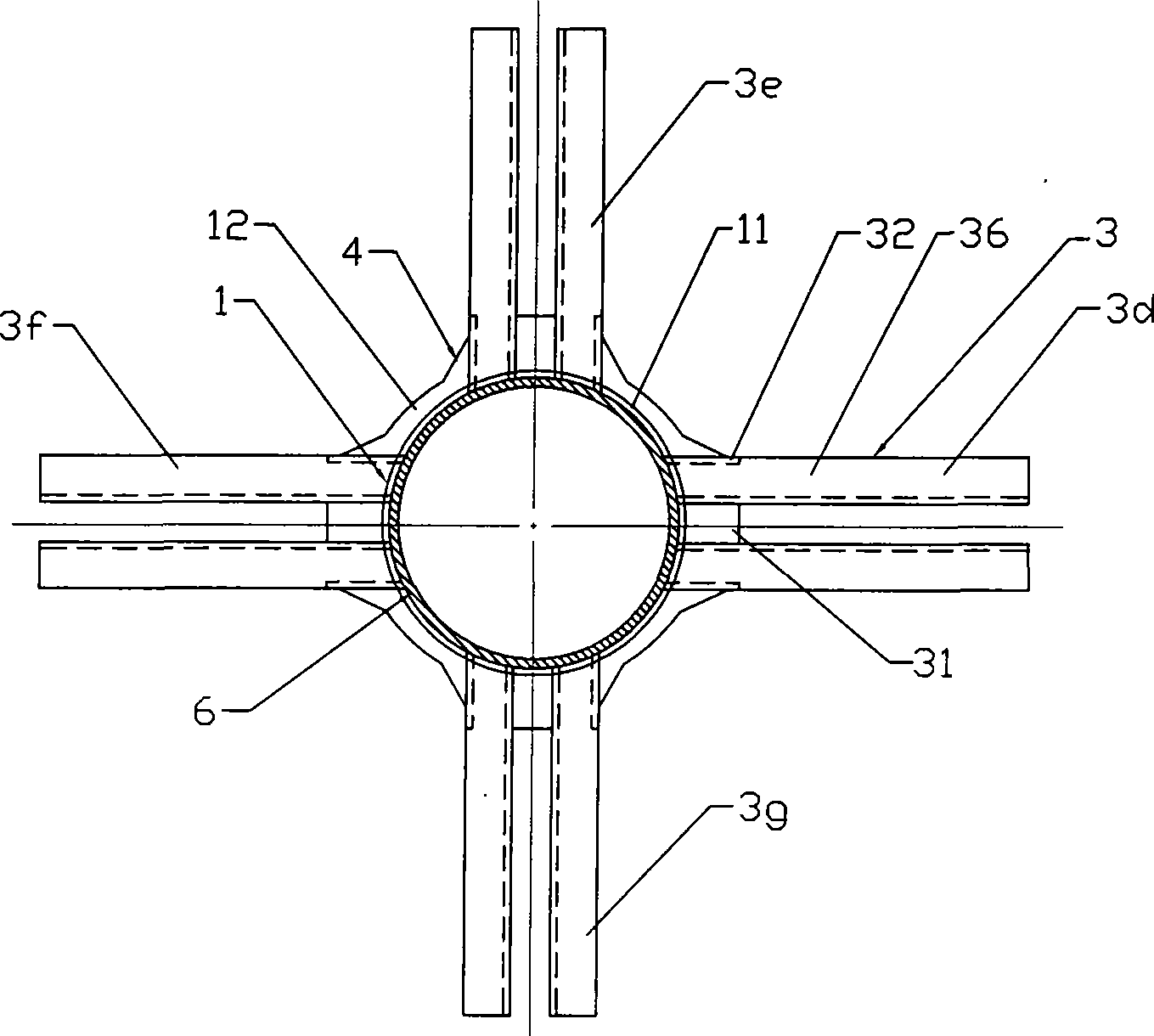

[0043] A specific implementation of the node component used to connect the steel pipe concrete column and the floor beam according to the present invention is as follows: image 3 , Figure 4 As shown, the difference from the previous embodiment is that the node members include steel pipes 6 and are spaced 90 along the horizontal plane in a "ten" shape. The four steel corbels 3d, 3e, 3f, 3g are arranged, and the four steel corbels 3d, 3e, 3f, 3g are arranged at the same height in each direction; the node member also includes only one upper ring plate 1 and one lower ring plate 2 ring plate assembly; the upper ring plate 1 and the lower ring plate 2 are full ring structures with the same structure: the vertical ring plates 11, 21 are cylindrical shapes compatible with the steel pipe 6, and the horizontal ring plates 12, 22 is a full circle, the upper ring plate 1 and the lower ring plate 2 are coaxial and arranged oppositely, and the roots of the four steel corbels 3d, 3e, 3f,...

Embodiment 3

[0045] A node member for connecting concrete filled steel pipe columns and floor beams according to the present invention is specifically implemented as follows Figure 4 , Figure 5 , as shown in Figure 6, different from Embodiment 1, the node members include steel pipes 6 and three steel corbels 3h, 3i, 3j arranged at intervals in a "Y" shape along the horizontal plane, which are arranged at different heights in each direction; the nodes The component also includes a ring plate assembly consisting of an upper ring plate 1 and two lower ring plates 2, 5; the upper ring plate 1 and one of the lower ring plates 2 are full ring structures with the same structure, and one of the steel corbels The protruding end of the upper web 35 at the root of 3h is inserted and welded to the upper ring plate 1 and the two horizontal ring plates 12, 22 of one of the lower ring plates 2; the other lower ring plate 5 is located on the above-mentioned upper ring plate 1 Between one of the lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com