Chocolate composition

A technology of chocolate and composition, applied in the field of chocolate, which can solve the problem that chocolate items are eaten later or used as gifts, unattractive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A series of 8 common chocolates were conventionally produced with the following general composition:

[0059] %

[0060] Sugar 46.9

[0061] Reduced-fat cocoa powder (10-12% fat) 21.0

[0062] Added fat / emulsifier mixture 32.0

[0063] Lecithin 0.1

[0064] Flavoring agent <0.05

[0065] Pre-crystallized cocoa butter (BC-50, Eulip), standard cocoa butter (“Astra A” pure primary express cocoa butter, ADM Cocoa B.V.), milk ester and sorbitan tristearate (GRINDSTED® STS 30KOSHER ) in various proportions to form the "Added Fat / Emulsifier Mixture" of the above general composition. The fat phase composition of the 8 chocolates labeled A-H is listed below (assuming reduced fat cocoa powder contains 11% cocoa butter and negligible lecithin).

[0066] Table 1

[0067] chocolate

[0068] The 50°C chocolate was passed through a scraped surface heat exchanger set to 20°C with cooling water to cool...

Embodiment 2

[0070] After 1 day at room temperature (20°C), the chocolates of Example 1 were tasted by a small "sensory analysis opinion panel", which agreed on the mouthfeel descriptions for the 5 samples (Table 2).

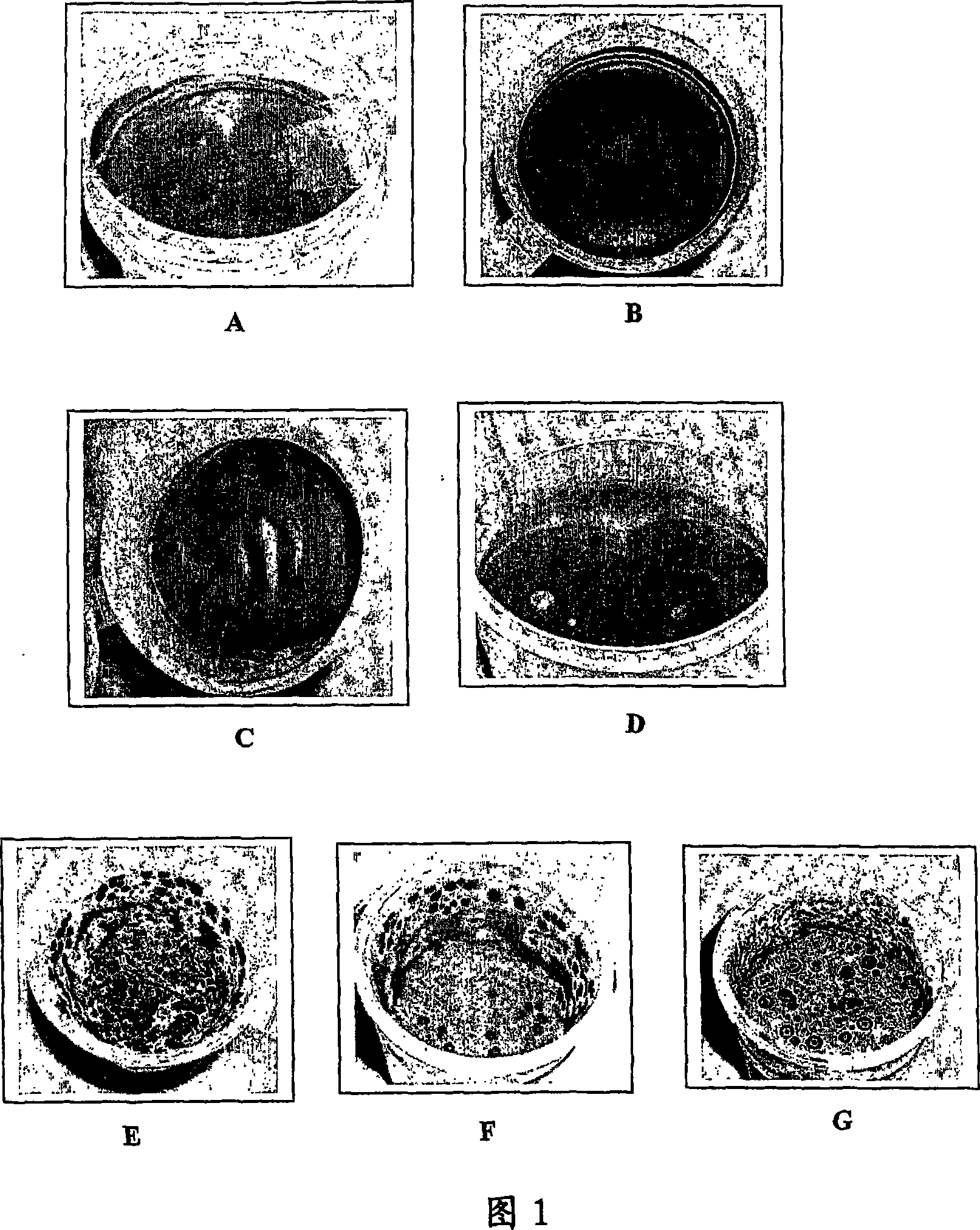

[0071] Each chocolate pot was heated to 60°C in a microwave oven to simulate the preparation of a chocolate fondue. The pots were allowed to cool and then inspected after storage for two weeks at 20°C. The degree of blooming was recorded (Table 2) and photographed. A series of photographs were taken of Samples G and H to show the development of bloom over time (Figure 17).

[0072] chocolate

[0073] It can be seen that the overall effect of reducing the amount of pre-crystallized cocoa butter is to reduce waxy mouthfeel but increase bloom. Without the addition of STS, the chocolate would bloom at the level of the already slightly waxy pre-crystallized cocoa butter (sample D). Surprisingly, addition of STS (sample C) eliminated both bloom and waxy mouthfeel. C...

Embodiment 3

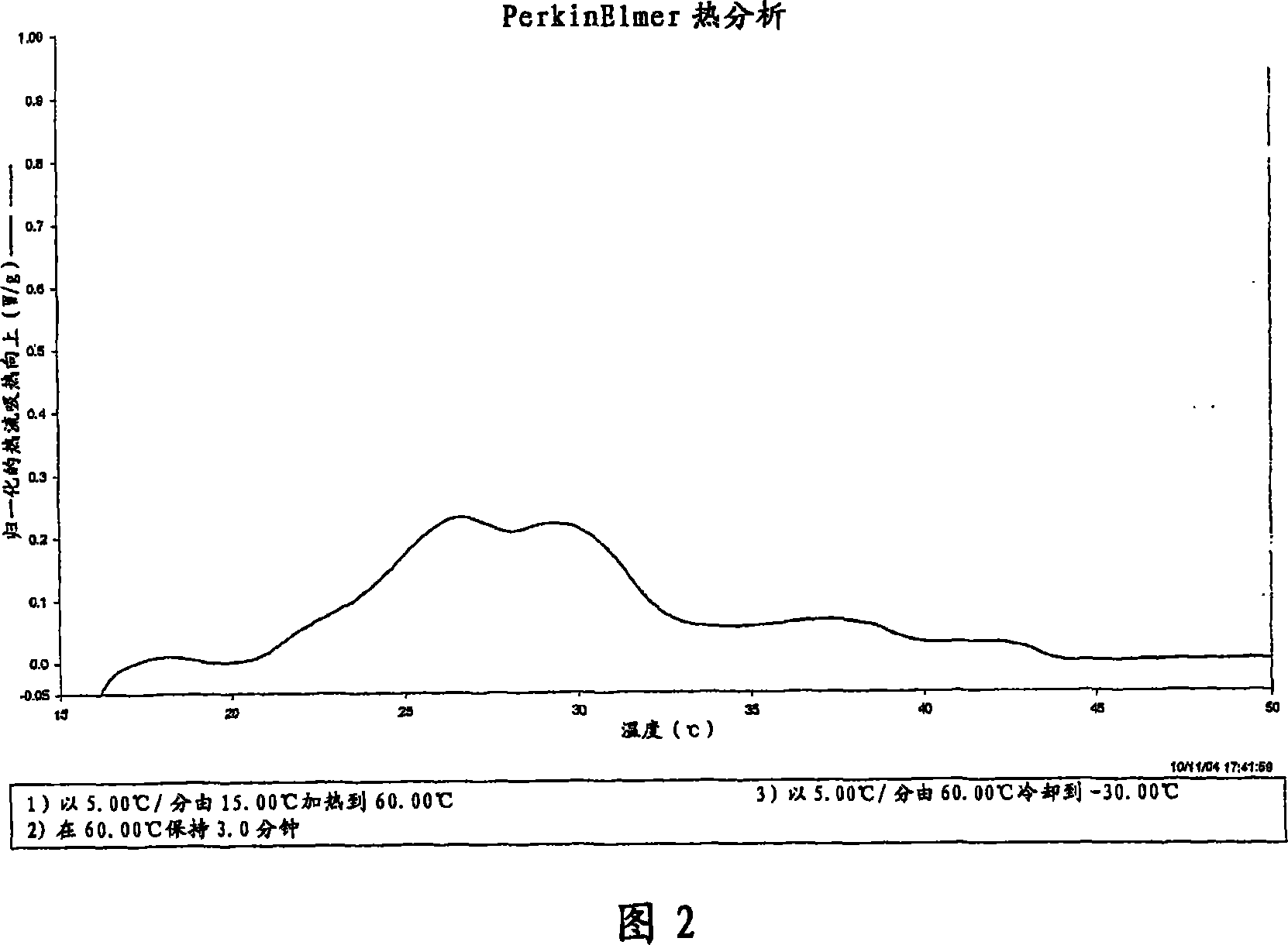

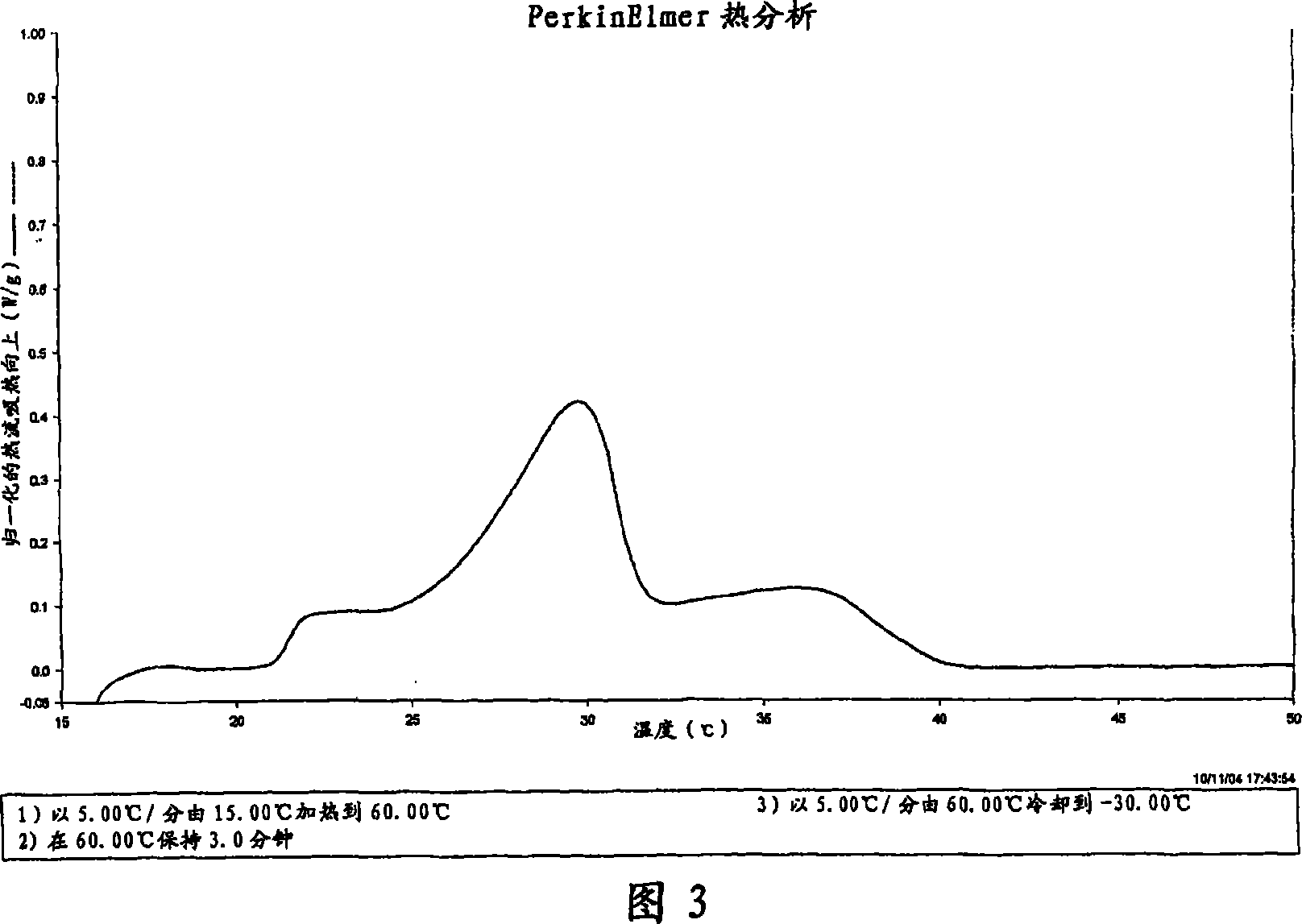

[0075] Chocolate samples from Example 1 were analyzed by differential scanning calorimetry (DSC) and gas chromatography (GC).

[0076]In a differential scanning calorimeter, a sample and a reference are heated or cooled at a controlled rate and the difference in heat flow between the sample and reference is measured. Typically, in this study, the reference object is an empty disk. If the sample is exothermic, e.g. due to crystallization, measure the exothermic heat flow, represented by the exothermic peak in the DSC curve used for this study, whereas if the sample requires more heat than the reference, e.g. due to melting, measure the endothermic heat flow , represented by the endothermic peak in the DSC curve. DSC analysis was performed with a Perkin Elmer DSC7 and data was analyzed with Perkin Elmer Pyris software. DSC was calibrated in the usual manner with indium standards.

[0077] Chocolates were stored at 20°C for 2 months prior to DSC analysis. A small sample of ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com