Constant-quantity material feeder of powder molding machine

A technology of feeding device and compression molding machine, applied in the field of machinery, can solve the problems affecting the normal operation of powder compression molding machine, low product yield, clogging of powder materials, etc., and achieves the effect of compact structure, high applicability and smooth passage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

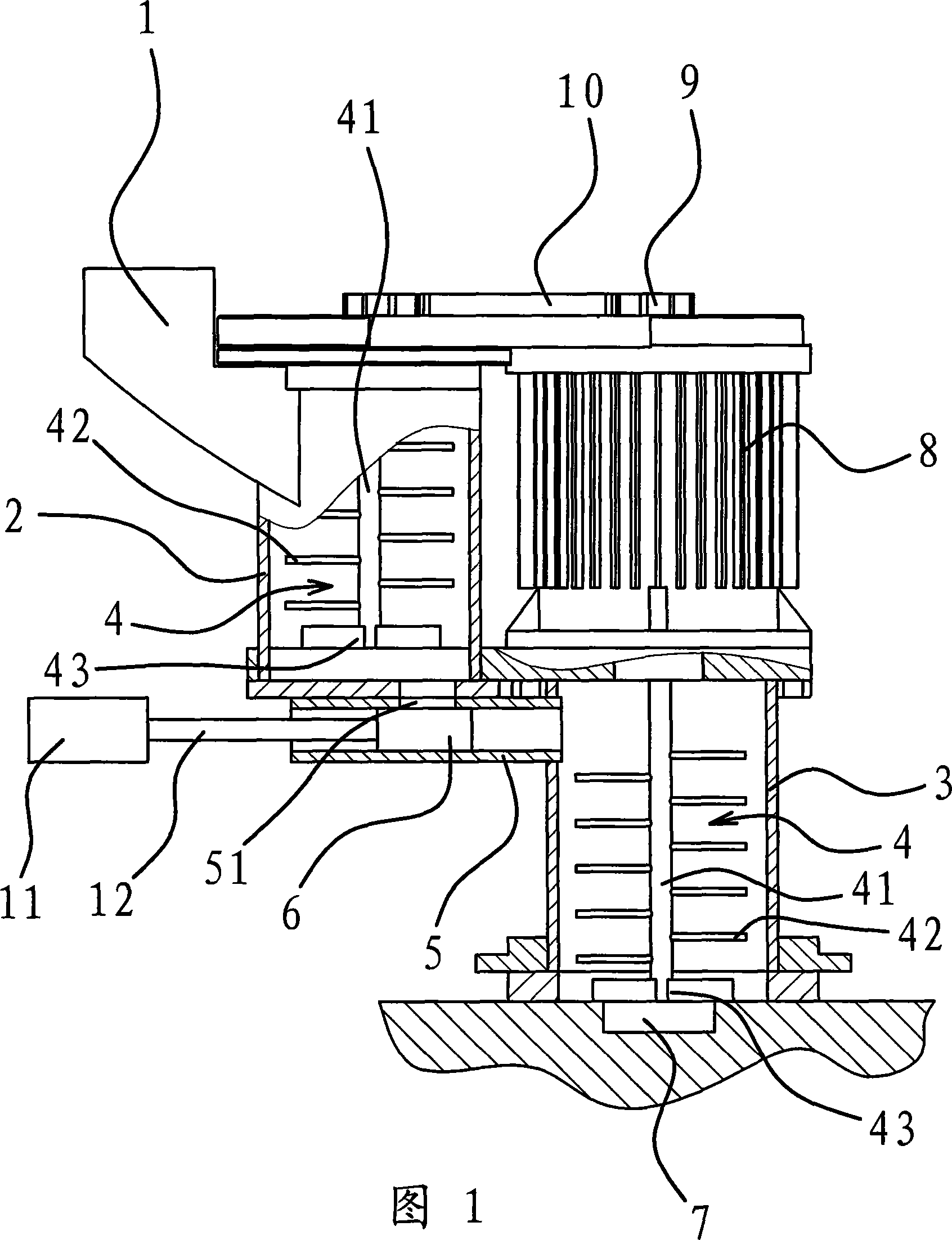

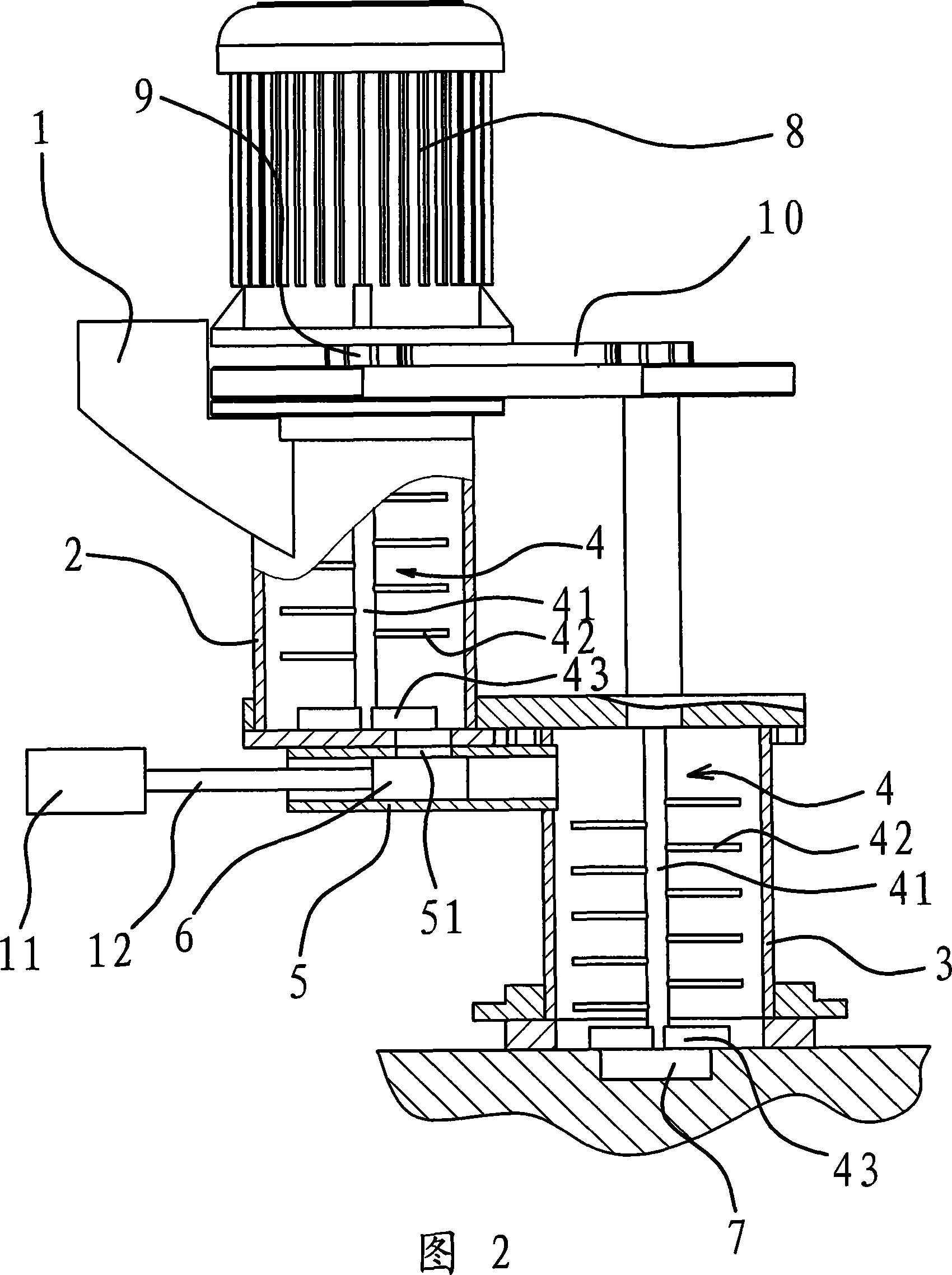

[0031] As shown in Figure 1, the constant feeding device of the powder compression molding machine is set at the mold 7 of the powder compression molding machine. It consists of a hopper 1, an upper feeding barrel 2, a lower feeding barrel 3 and a feeding mechanism.

[0032] The hopper 1 is in communication with the upper feeding barrel 2, and the upper feeding barrel 2 is located at the upper part of the lower feeding barrel 3. The feeding mechanism is located between the upper feeding barrel 2 and the lower feeding barrel 3, and it connects the upper feeding barrel 2 and the lower feeding barrel 3 with each other. Among them, the lower feeding barrel 3 is located on the upper part of the mold 7 of the powder molding machine.

[0033] In order to allow the powder materials to pass smoothly, a feeding paddle 4 is provided in both the upper feeding barrel 2 and the lower feeding barrel 3. The feeding paddle 4 is composed of a drive shaft 41 and a number of feeding bars 42. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com