Process of preparing potassium sulfate with potassium containing bittern of magnesium sulfate subtype

A magnesium sulfate subtype, potassium sulfate technology, applied in the direction of alkali metal sulfite/sulfite, bisulfite preparation, chemical instruments and methods, etc., can solve the problems of high energy consumption, complicated process, long process, etc. Achieve the effect of high yield, simple process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

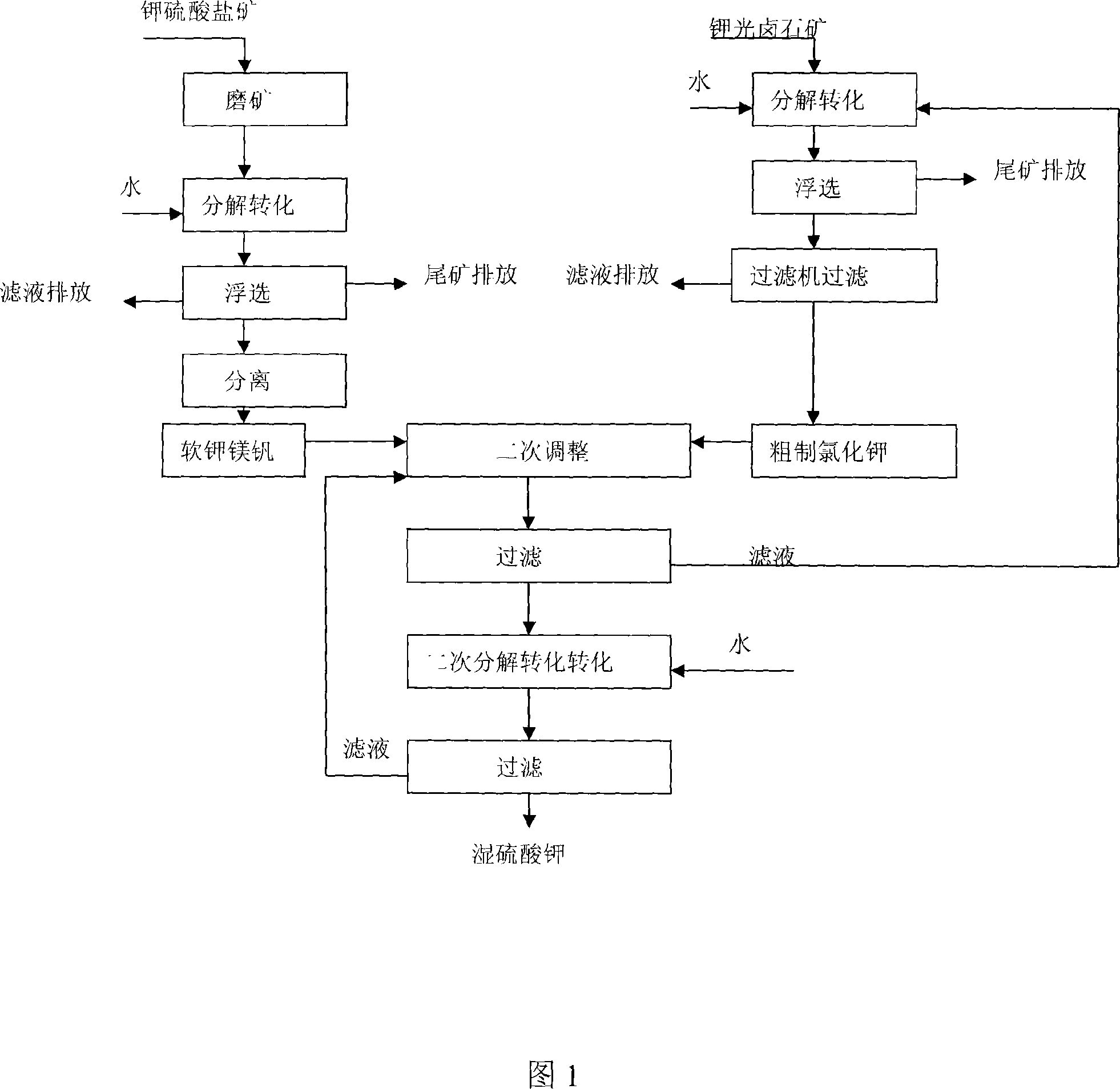

Image

Examples

Embodiment Construction

[0020] ①Put potassium-containing magnesium sulfate subtype raw brine into sodium chloride salt fields and evaporate in the sun to precipitate most of the sodium chloride. The salt pool continues to evaporate and separate out one section of potassium-containing sulfate; when the first section of sulfate is precipitated to a certain degree (determined according to the phase diagram calculation result), this brine is poured into the second section of sulfate pool to continue to separate out the second section of potassium-containing sulfate to obtain potassium-containing sulfate. The main sulfate mine. When the second section of sulfate brine is evaporated to the saturation of carnallite, pour the brine into a section of carnallite evaporation pool to evaporate, and when the precipitation of carnallite in the carnallite pool reaches about 80% of the calculated amount, the Pour into the second-stage carnallite pool and continue to evaporate until the magnesium chloride is saturate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com