Process of preparing 1,4-cyclohexane dimethand

A technology of cyclohexanedimethanol and terephthalic acid, which is applied in 1 field and can solve the problems of expensive precious metals, increased catalyst consumption, and high catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In the method for preparing 1,4-cyclohexanedimethanol of the present invention, the main steps are: mixing terephthalic acid and water-containing medium at a weight ratio of 1: (5-20), and in the presence of a catalyst Hydrogenation is carried out by introducing hydrogen gas. The reaction temperature is 100°C to 300°C (preferably, the reaction temperature is 150°C to 250°C), the hydrogen pressure is 4.0 MPa to 10.0 MPa (preferably, the hydrogen pressure is 6 MPa to 10 MPa), and the reaction time is 3 hours to 6 hours.

[0015] Wherein, the catalyst is a supported catalyst, and its active components include Ru, Sn and B, and the content of Ru is 3wt%-10wt% (based on the weight of the carrier used), and the molar ratio of Ru to Sn is 0.8-2.0 , The molar ratio of B to the sum of the moles of Ru and Sn is 3-10; the carrier of the catalyst is Al 2 O 3 The average particle size is preferably 80-200 mesh; based on the total weight of the reaction system, the weight dosage of the c...

Embodiment 1~10

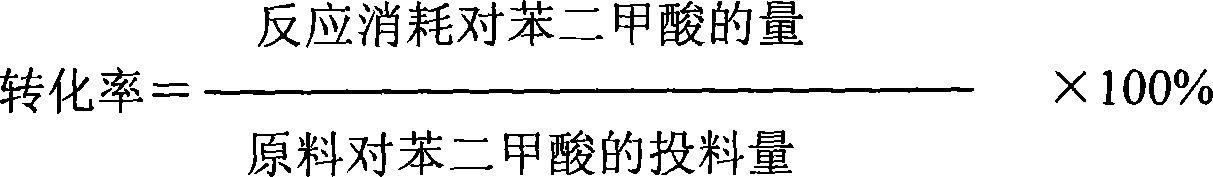

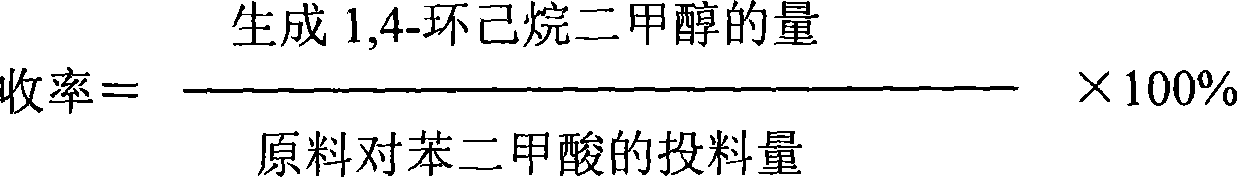

[0022] Place 150 g of solvent water and the required amount of terephthalic acid in a 300 ml autoclave, and add the required amount of catalyst in proportion. After the autoclave is sealed, the air in the autoclave is drawn out, and then hydrogen is introduced for replacement. Then hydrogen gas is passed through with stirring and heating, and the reaction is carried out according to preset conditions, and the hydrogen pressure is maintained until the reaction is completed. After cooling, the pressure is released and the catalyst is filtered out. The reaction liquid was analyzed by gas chromatography, and the product concentration was calculated according to the internal standard method. The acid value determination method is used to calculate the concentration of unreacted terephthalic acid.

[0023] The catalyst composition and amount, reaction conditions and reaction results used in each embodiment are shown in Table 1.

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com