Sewage and surface water heat pump open tunnel type heat exchanging tank heat exchanging method and apparatus thereof

A heat exchange device and surface water technology, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of heavy operation workload, complex system process, and low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

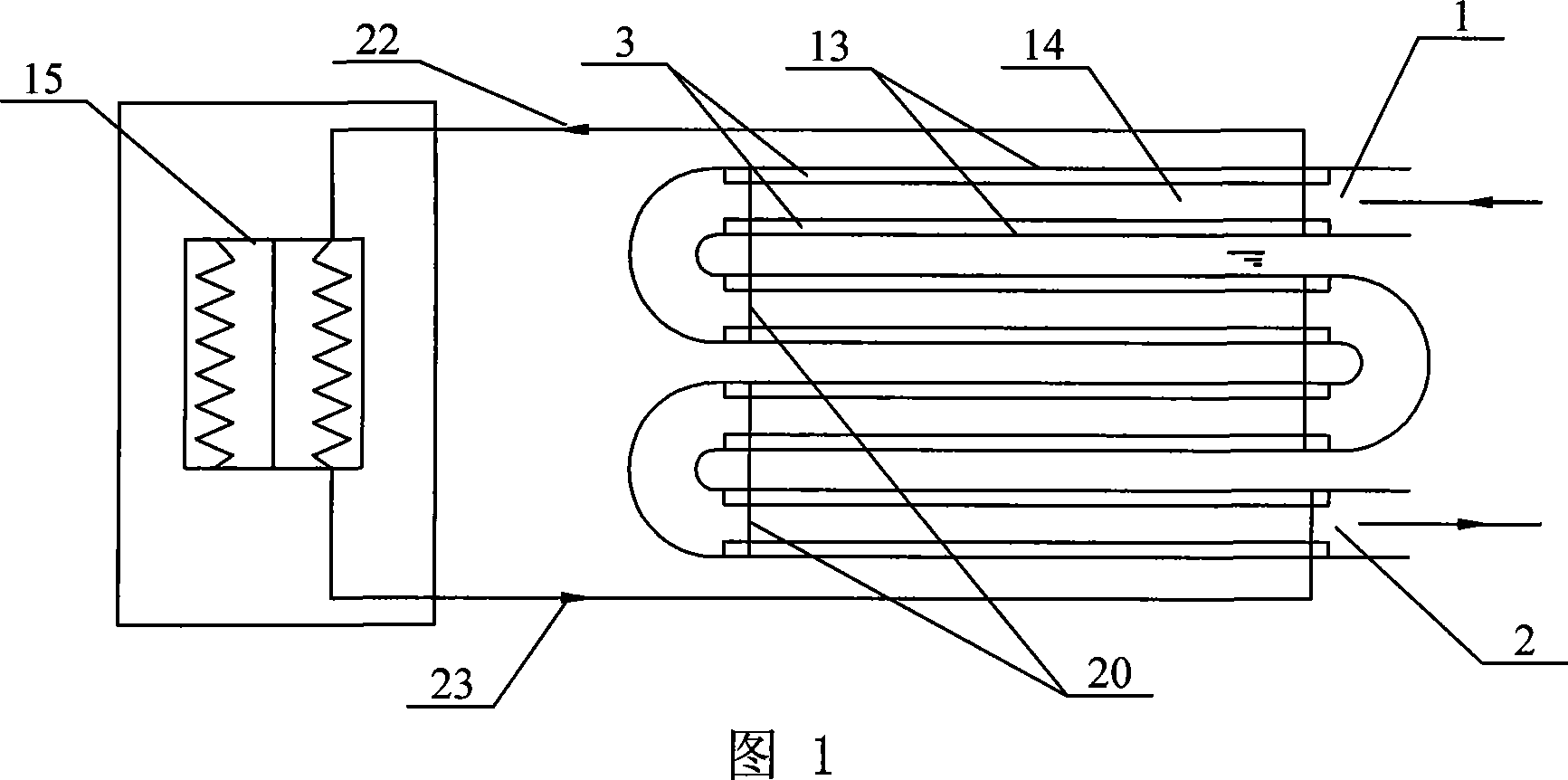

[0009] Specific embodiment one: (see Fig. 1) the steps of the heat exchange method of the sewage and surface water heat pump open channel heat exchange tank of the present embodiment are as follows: 1. Send sewage or surface water into the flow channel with a cross-sectional area ≥ 300mm×40mm, The inclined slope or hydraulic gradient of the flow channel is 0.5% to 6%, and the sewage or surface water flows in the flow channel in the form of a partially filled open channel; 2. The flow channel through which the sewage or surface water flows is a long straight channel or a broken line Runners; 3. Arrange tube bundles or plates on the bottom or both sides of the runners, and the heat exchange medium (clear water or refrigerant, etc.) flows in the cavity of the tube bundles or plates to form heat exchange grooves; 4. The wall of the runners The tube bundles or plates on the flow channel wall are connected (in series or in parallel), and the heat exchange medium and sewage or surface...

specific Embodiment approach 2

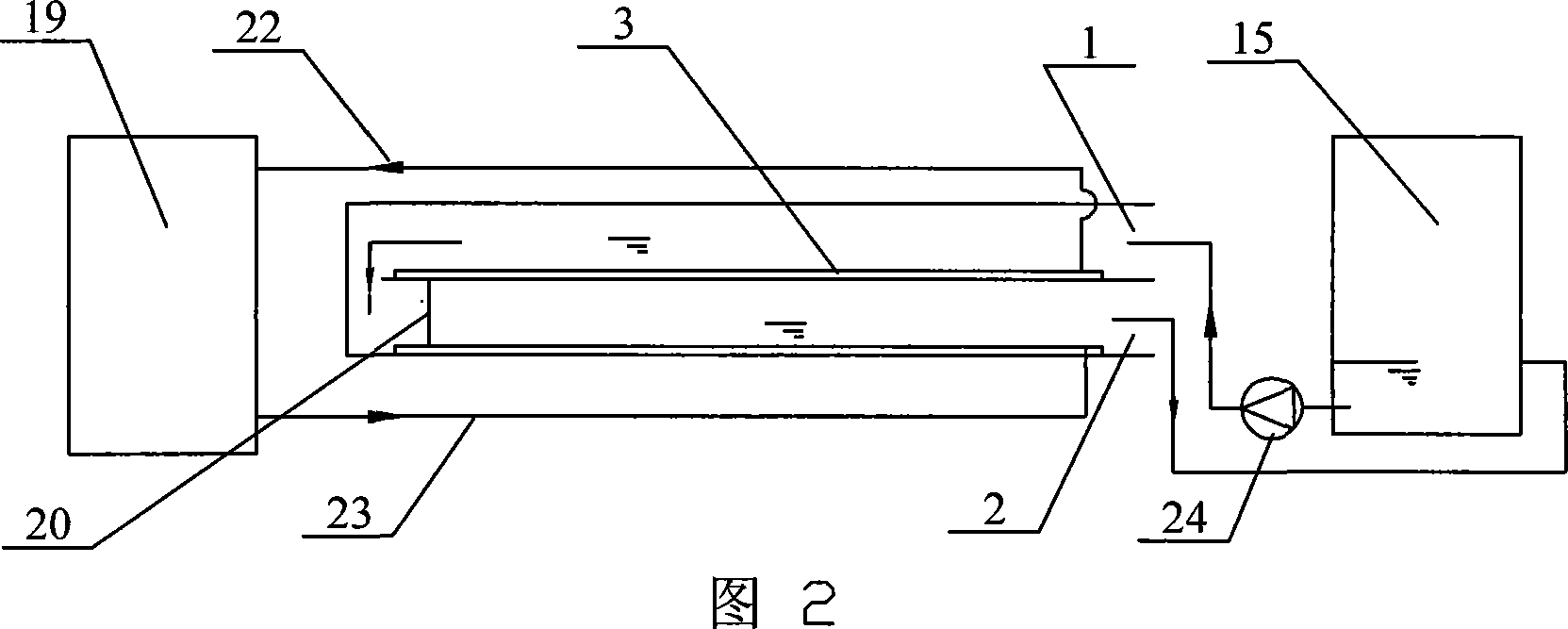

[0010] Specific embodiment two: (see Figure 2) This embodiment is a sewage or surface water open channel type long straight channel or heat exchange tank flow heat exchange method, in a certain section between the water source and the building (or machine room) Underground or on the ground, or when there is enough space in the machine room and other selected places, set up a long straight channel or a few series channels for sewage, and arrange heat exchange tube bundles or plates on the bottom or both sides of the channel to form a long Direct heat exchange tank. Sewage or surface water is pumped into a single channel or a few channels in series to flow in the open channel, and the heat exchange medium flows in the tube bundle or plate cavity.

specific Embodiment approach 3

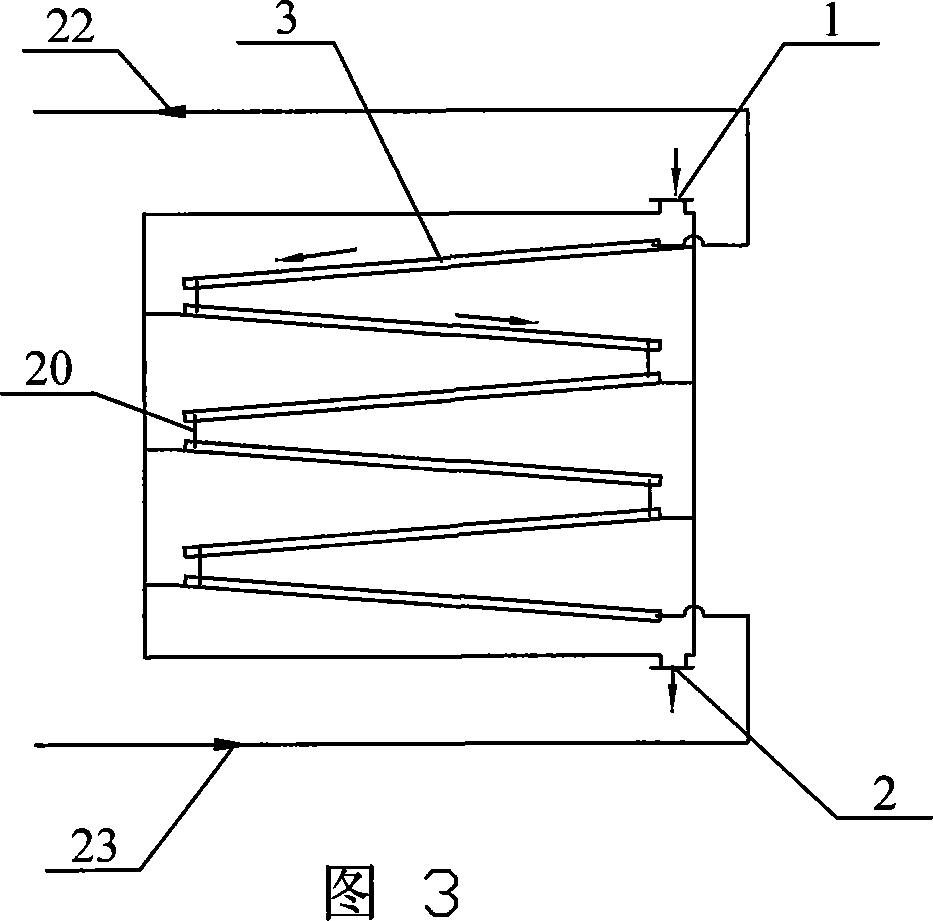

[0011] Specific embodiment three: (see Fig. 3 and Fig. 4) This embodiment is a flow heat exchange method in which multiple flow channels or multiple heat exchange tanks of sewage or surface water open channel are combined in series. The length of the heat groove is small, and multiple heat grooves are combined in series to form a zigzag flow channel. Sewage flows from top to bottom, from the first flow channel or heat exchange tank to the last flow channel or heat exchange tank one by one, and the flow in all flow channels or heat exchange tanks is open channel flow. Sewage or surface water exchanges heat with the heat exchange medium through the tube bundle or plate surface in the flow channel. The tube bundles or plate cavities in each channel or heat exchange tank can be connected in series or connected in series and in parallel to control the flow rate and flow resistance of the heat exchange medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com