Frame-structure ripple ceramic wet-type cleaner

A technology of wet dust collector and frame structure, which is applied in the direction of chemical instruments and methods, use of liquid separating agent, lighting and heating equipment, etc. It can solve the problems of not achieving the best dehydration effect, inconvenient transportation, long production cycle, etc., and achieve The effect of simple structure, convenient transportation and short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

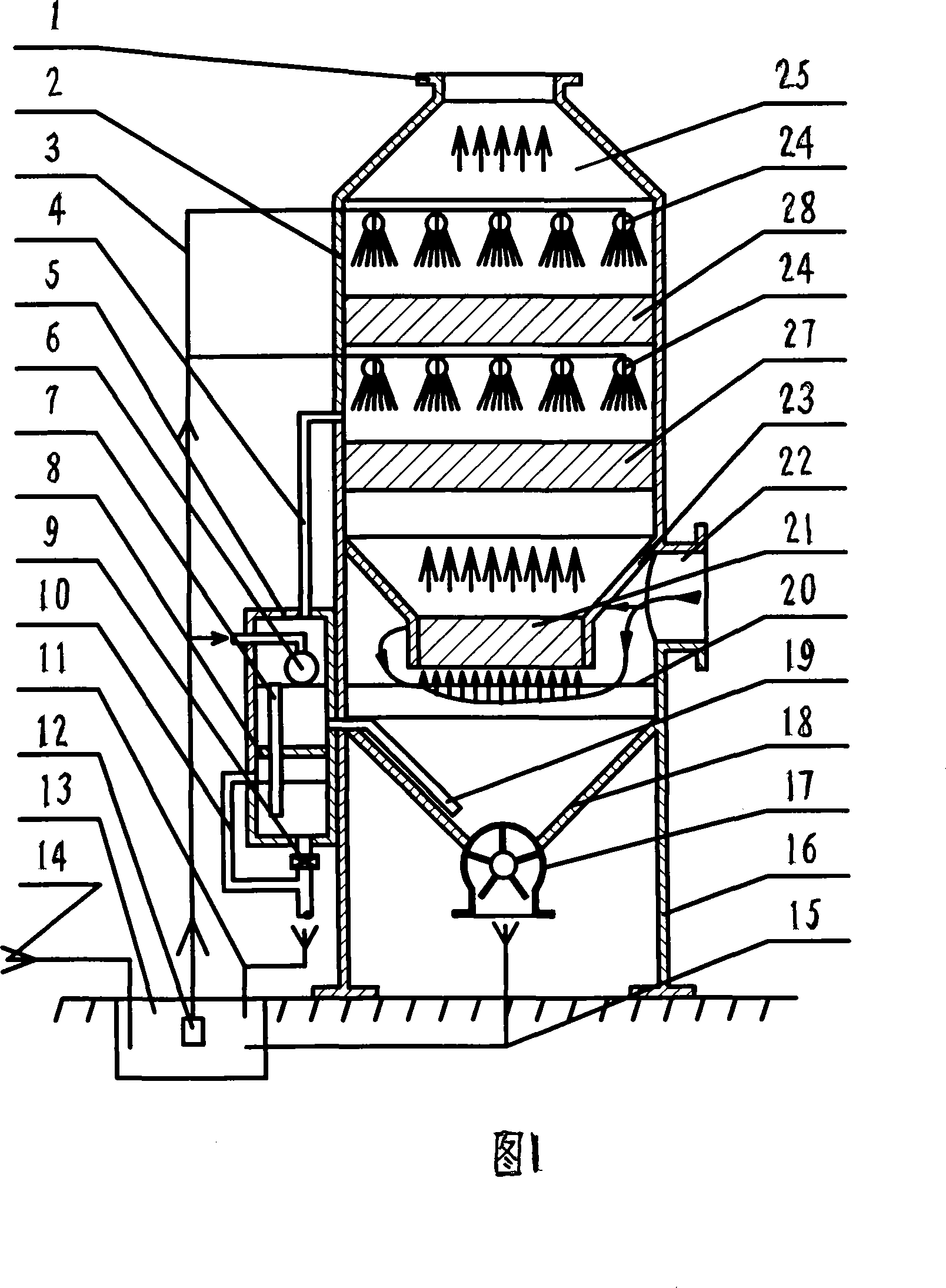

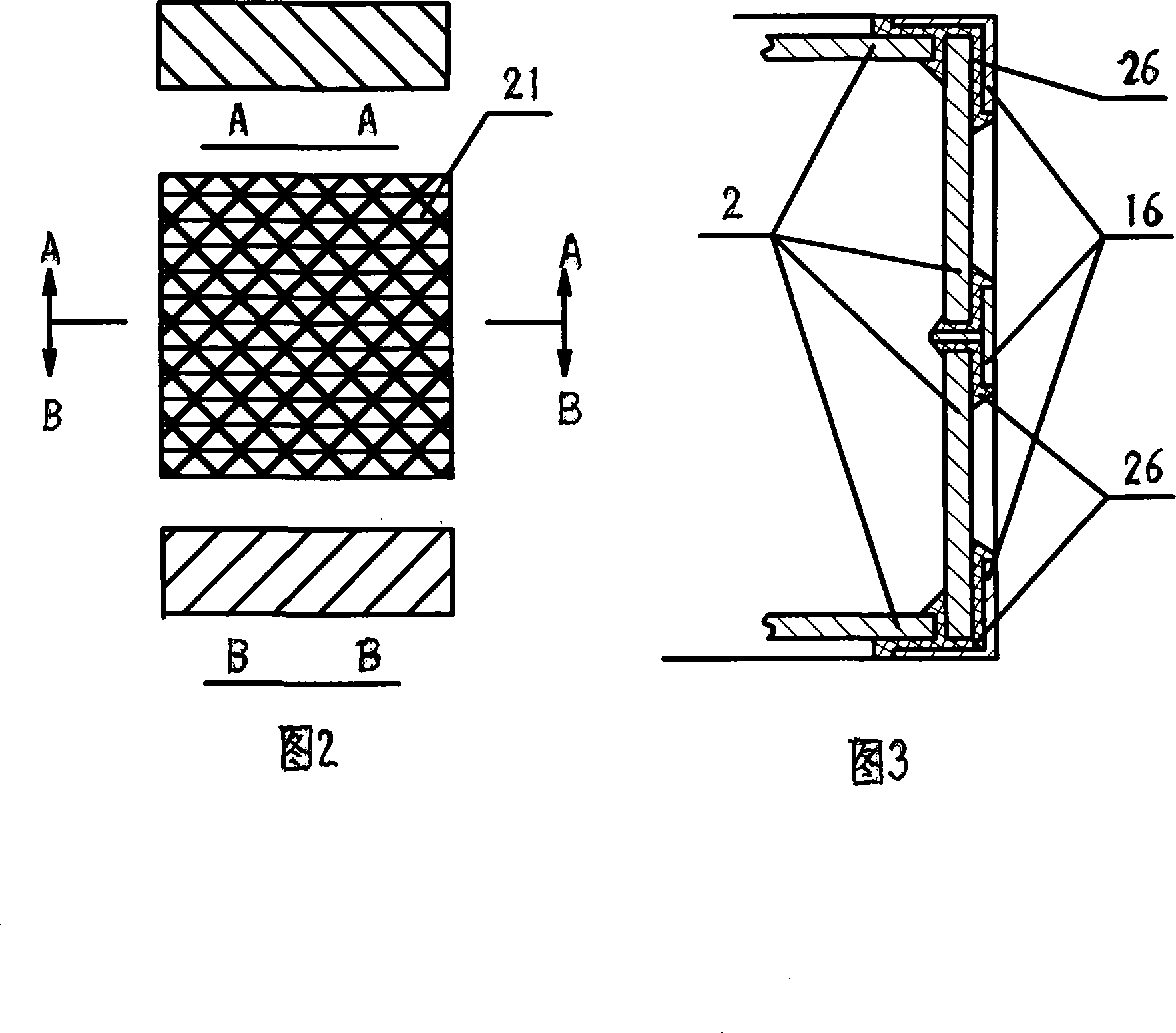

[0015] The gusset [2] is bonded to the frame [16] with structural sealant [26] to form a shell of the frame structure, and the gusset [2] can be made of tempered glass or laminated resin board, polymer plastic board and other materials , the frame [16] is a metal frame, the structural sealant [26] is a polyurethane modified structural sealant, the lower end of the smoke outlet [1] is the upper corrugated ceramic [28], and the smoke inlet [22] is equipped with Expanding pipe [23], the lower corrugated ceramics [21] is installed at the lower end of the expanding pipe [23], the middle corrugated ceramics [27] is set between the upper corrugated ceramics [28] and the lower corrugated ceramics [21], and the ash hopper The outer upper end of [18] is equipped with a water-adding and overflowing bucket [5], and through the connecting pipe [19], the dust-accumulating bucket [18] and the water-adding and overflowing bucket [5] are connected, in order to make the water-adding and overflow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com