Gas sensor, and internal combustion engine and transportation apparatus incorporating the same

A gas sensor, oxide semiconductor technology, applied in the direction of material resistance, etc., can solve the problems of complex oxygen sensor structure, complex oxygen sensor structure, complex structure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the present invention is not limited to the following embodiments.

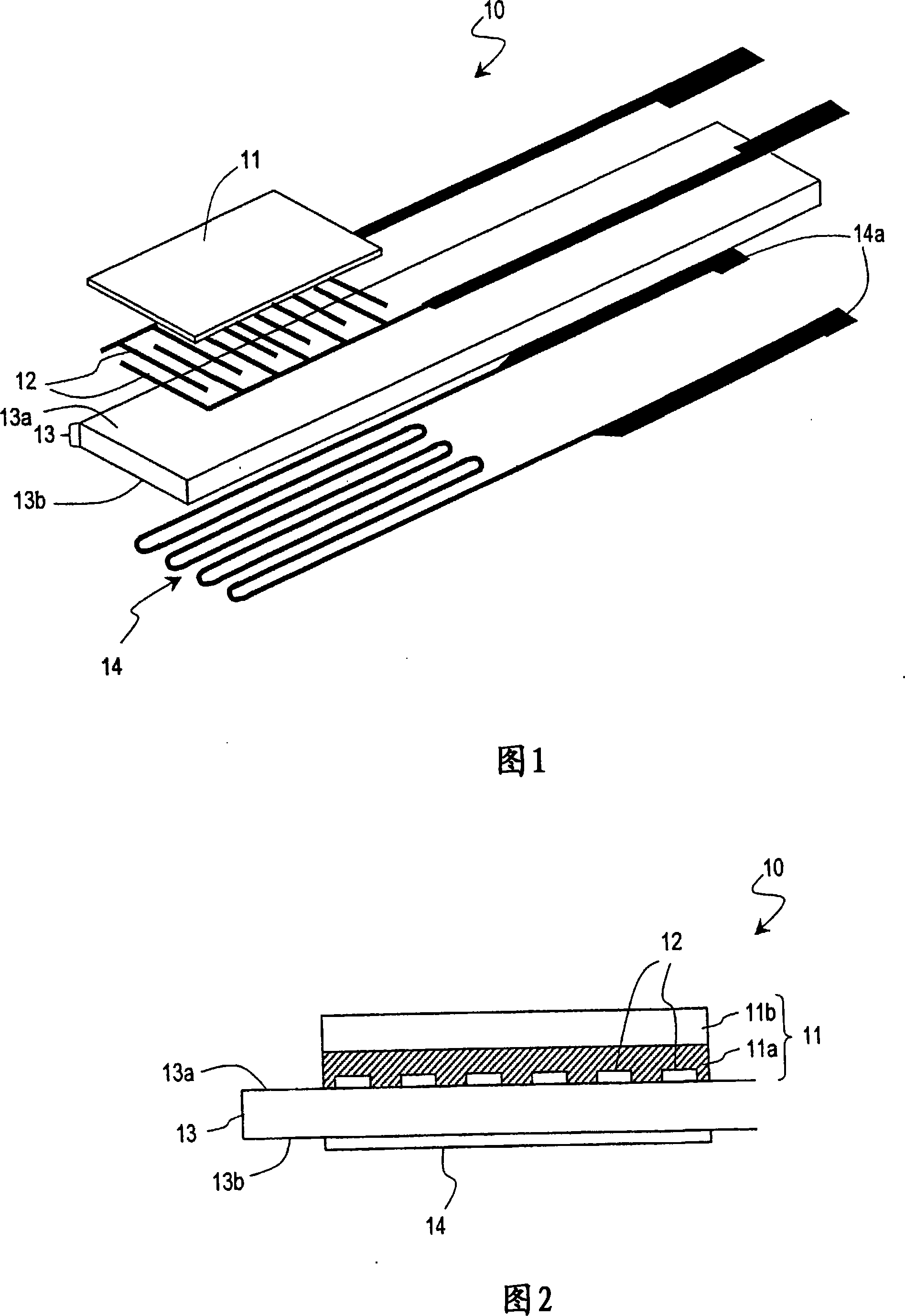

[0055] First, the configuration of the gas sensor 10 according to the present embodiment will be described with reference to FIGS. 1 and 2 . 1 and 2 are respectively an exploded perspective view and a cross-sectional view schematically showing the gas sensor 10 . The gas sensor 10, as shown in FIGS. 1 and 2, is a resistive oxygen sensor including an oxide semiconductor layer 11 formed of an oxide containing cerium and a detection electrode 12 for detecting the resistivity of the oxide semiconductor layer 11. .

[0056]The oxide semiconductor layer 11 and the detection electrode 12 are supported by a substrate 13 . The substrate 13 is formed of an insulator such as alumina and magnesia. The substrate 13 has a main surface 13 a and a back surface 13 b facing each other, and the oxide semicondu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com