Substrate carrier capable of removing electrostatics

A carrier and substrate technology, applied in the direction of static electricity, circuits, electrical components, etc., can solve problems such as process errors, achieve the effect of improving yield and improving static interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

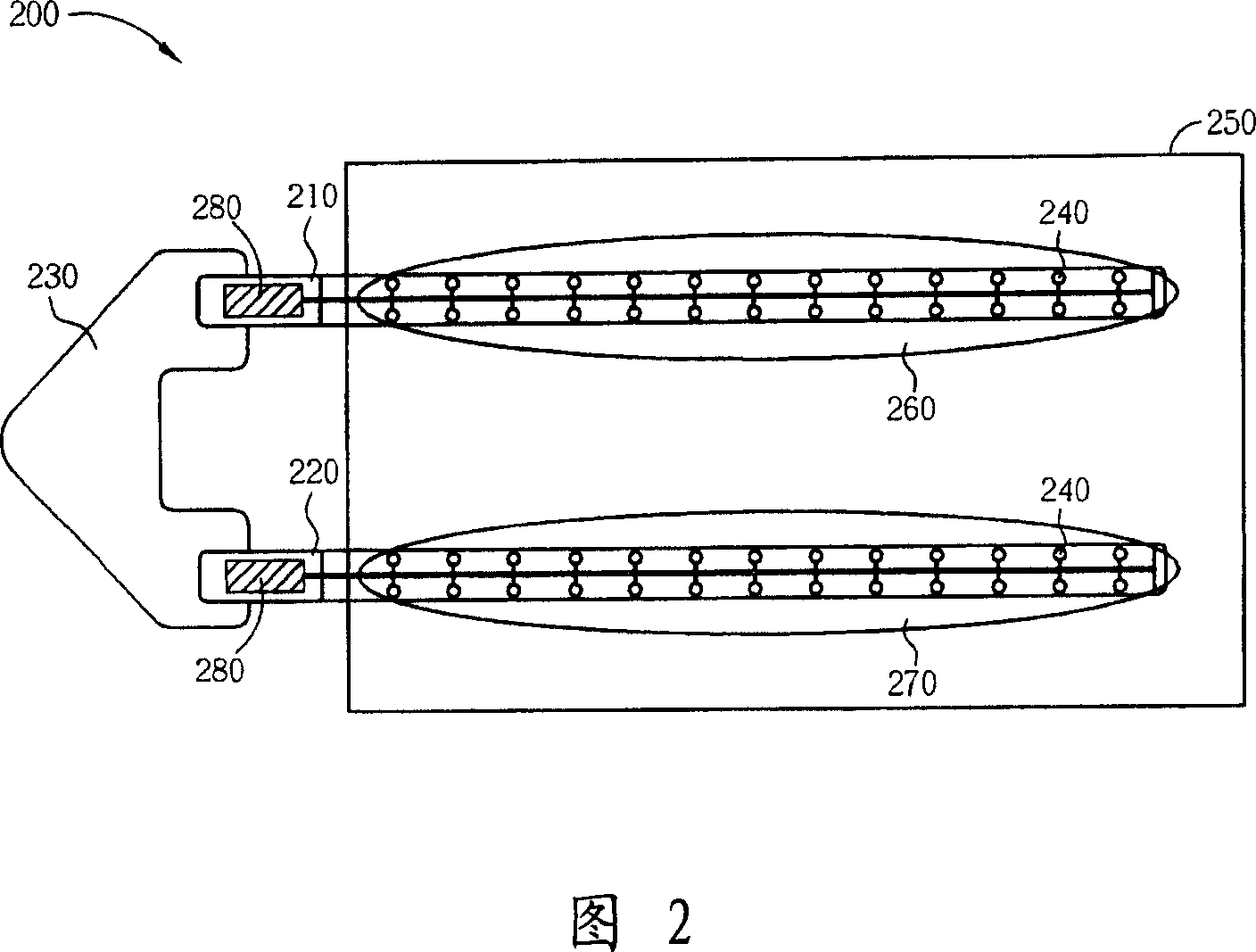

[0020] Please refer to FIG. 2 , which is a schematic diagram of a robot forklift 200 of the present invention. As shown in FIG. 2 , the robot arm 200 also includes support modules 210 , 220 and a connection module 230 . The connection module 230 is connected to the robot body, and the support modules 210, 220 are connected to the connection module 230 to provide a support force for the support modules 210, 220 through the connection force between the support modules 210, 220 and the connection module 230. . Therefore, the supporting modules 210 and 220 can be used to carry the glass substrate 250 to transport the glass substrate 250 to different machines.

[0021] Same as the robot arm 100 , the support modules 210 and 220 of the robot arm 200 of the present invention are also provided with a plurality of contact pads 240 . When the support modules 210, 220 transport the glass substrate 250, these contact pads 240 will provide multiple contact surfaces of the glass substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com