Fluidized-bed reactor for powder material

A technology of powder material and reaction device, which is applied in the direction of heating to dry solid materials, hearth furnace, drying solid materials, etc., can solve the problems such as chemical reaction can not be carried out, powder materials are easy to stick, and drying time is prolonged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

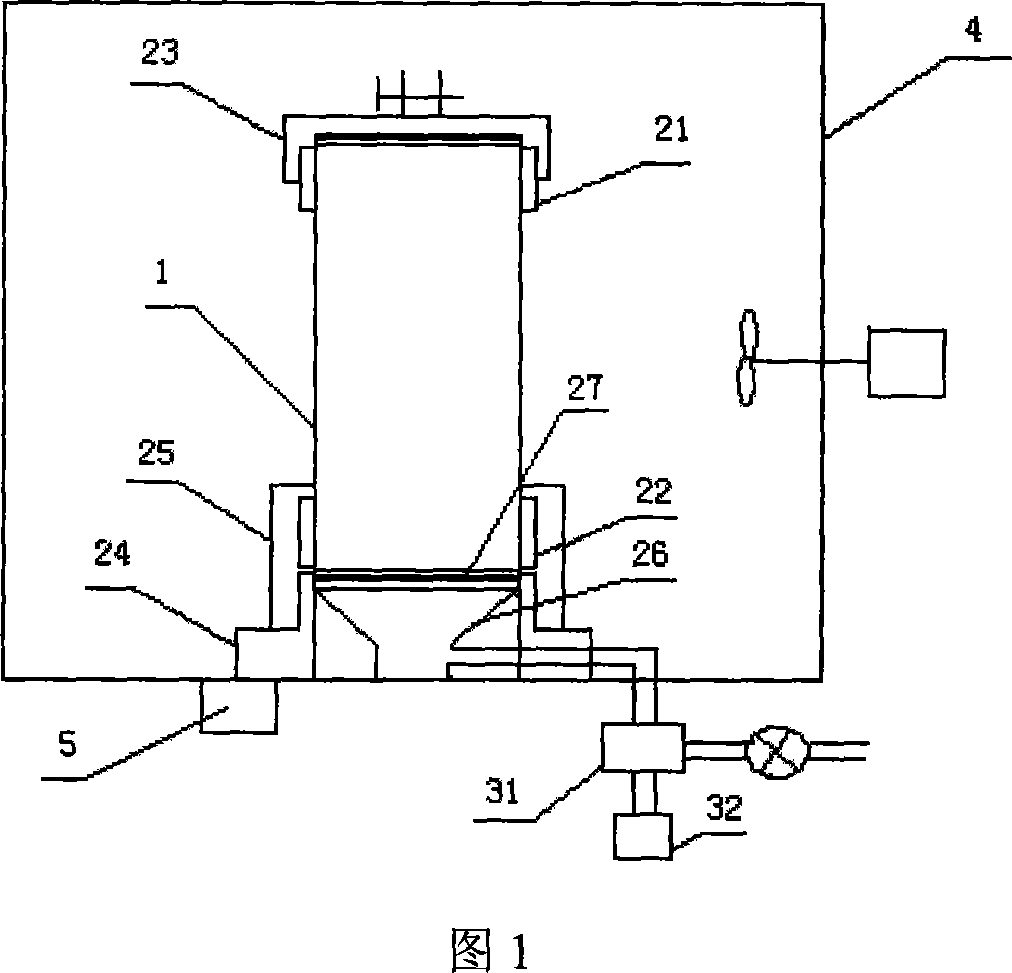

[0018] As shown in Figure 1, the ebullated bed apparatus for this chemical reaction mainly includes a glass main reactor. A set of PTFE joints, a gas heating system, a heating constant temperature system, and a vibration device.

[0019] The height of the reactor is 50 cm, the inner diameter is 6 cm, and the outer diameter is 7 cm. If the mass and gas flow rate of the materials participating in the reaction change greatly, the diameter and height of the reactor can be changed accordingly.

[0020] The polytetrafluoroethylene combined joint mainly includes an upper polytetrafluoroethylene ring 21, a lower polytetrafluoroethylene ring 22, a polytetrafluoroethylene top cover 23, a polytetrafluoroethylene base 24, a polytetrafluoroethylene screen 27, polytetrafluoroethylene Fluoroethylene collar 25, polytetrafluoroethylene funnel type air guide port 26, last polytetrafluoroethylene ring 21, following polytetrafluoroethylene ring 22 two parts are the same polytetrafluoroethylene r...

Embodiment 2

[0025] The fluidized bed chemical reaction device performs solid-phase polycondensation of polyethylene terephthalate, a powder material with a particle size of 300 mesh after crushing. Nitrogen flow is controlled at 1.2m 3 / g.h, the nitrogen temperature is controlled at 210°C, the oven temperature is controlled at 210°C, and the reaction time is 2 hours. After the reaction finished, the viscosity of sampling analysis was 0.988dL / g.

Embodiment 3

[0027] The fluidized bed chemical reaction device performs solid-state polycondensation on the powder material polyethylene terephthalate with a particle size of 200 mesh after crushing. Nitrogen flow is controlled at 1.2m 3 / g.h, the nitrogen temperature is controlled at 220°C, the oven temperature is controlled at 220°C, and the reaction time is 2 hours. After the reaction finished, its viscosity of sampling analysis was 1.187dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com