Producer of bowled instant-noodles trade mark

A production device and instant noodle technology, applied in the direction of cardboard items, etc., can solve the problems of high wage costs for workers, occupy a large area of the factory building, and waste raw materials, etc., and achieve the effects of low labor intensity, small occupied area of the factory building, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

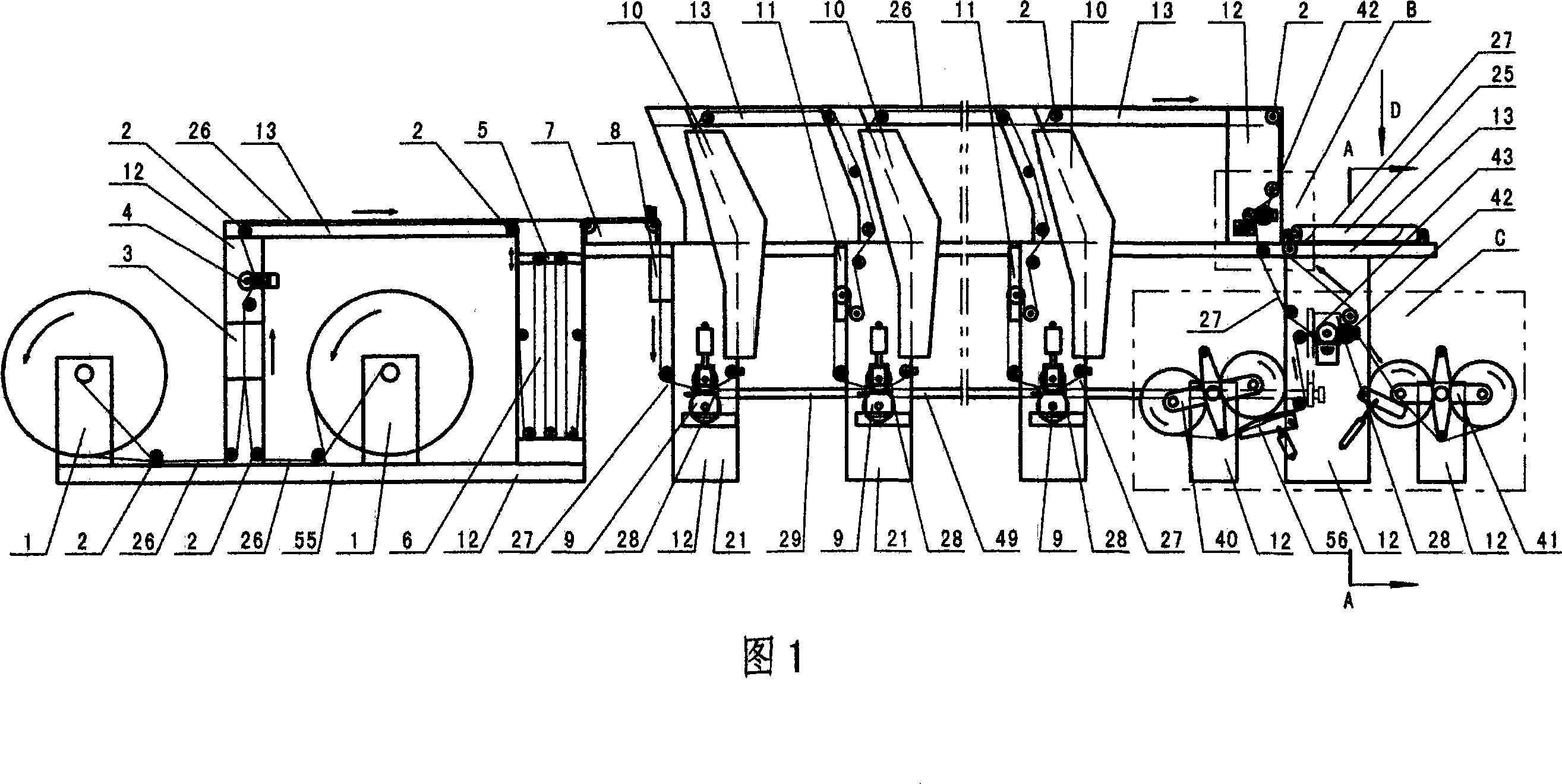

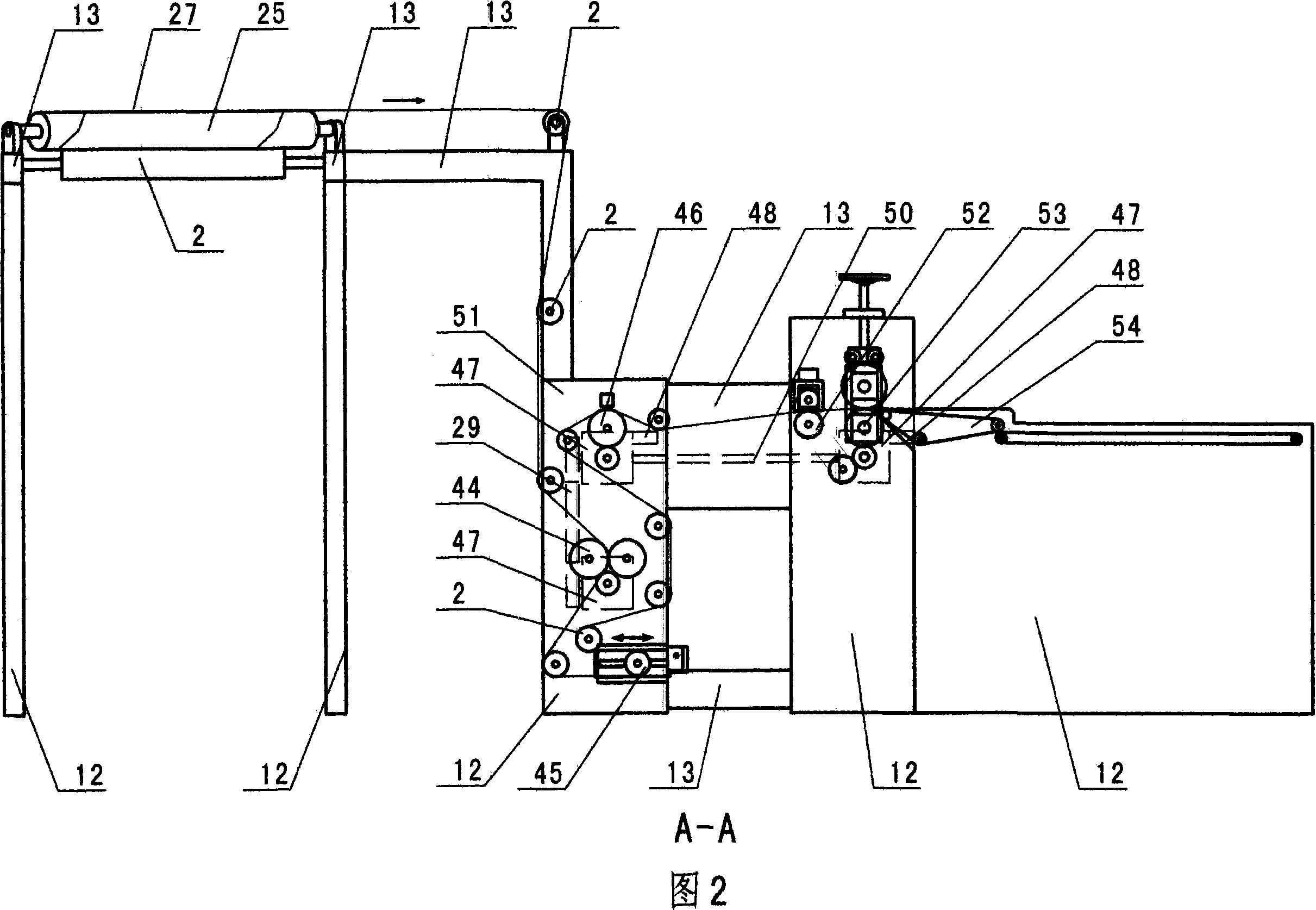

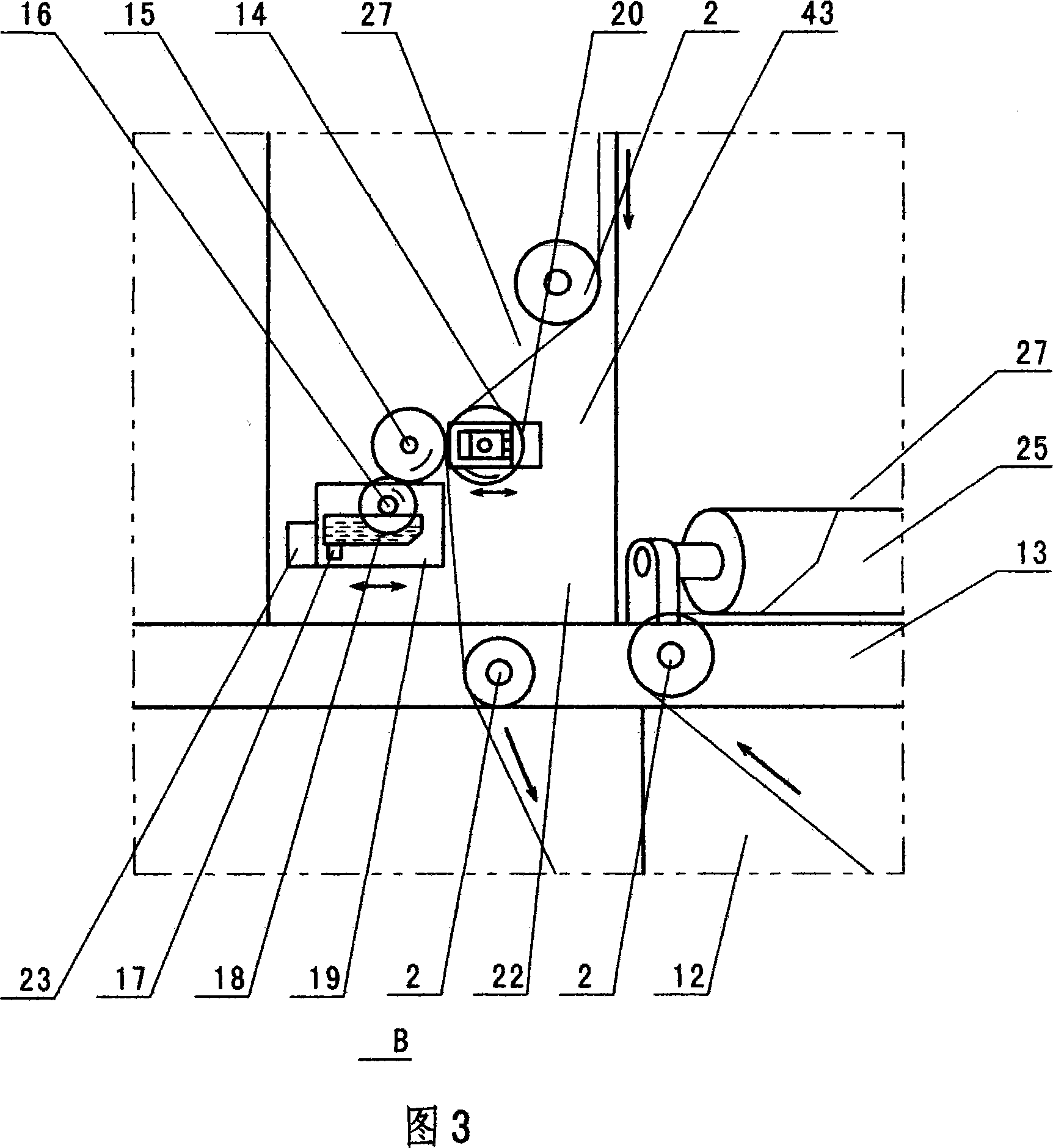

[0024]The accompanying drawings are further commented below. Referring to Figure 1, the instant noodle bowl label paper production device is composed of a deviation correction mechanism 7, a printing mechanism 9, an oven 10, a plate setting system 11, a film unwinding mechanism 40, a film winding mechanism 41, a mirror surface Calendering mechanism 42, continuous oiling mechanism 43, power device 49, power device 50, alignment mechanism 51, die-cutting mechanism 53, collecting mechanism 54, double-station non-stop unwinding mechanism 55; The connecting plates 13 are connected to each other to form a rigid integral frame. The cylindrical material roll 1 is supported on the fixed frame 12 and can be rotated around its axis in the direction of the arrow, and is uncoiled by the known unwinding method of the roll-shaped material to form the instant noodle bowl material 26, and the paper guide roller 2 is supported on the fixed frame. 12 or on the connecting plate 13 of the fixed ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com