Precoating milliosmol water purifier with filtration membrane

A micro-penetration and pre-coating technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of small activated carbon and other filter materials escaping, unsatisfactory filtration effect, short contact time, etc., to achieve firm and uniform pre-coating , The effect of compact structure and large water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

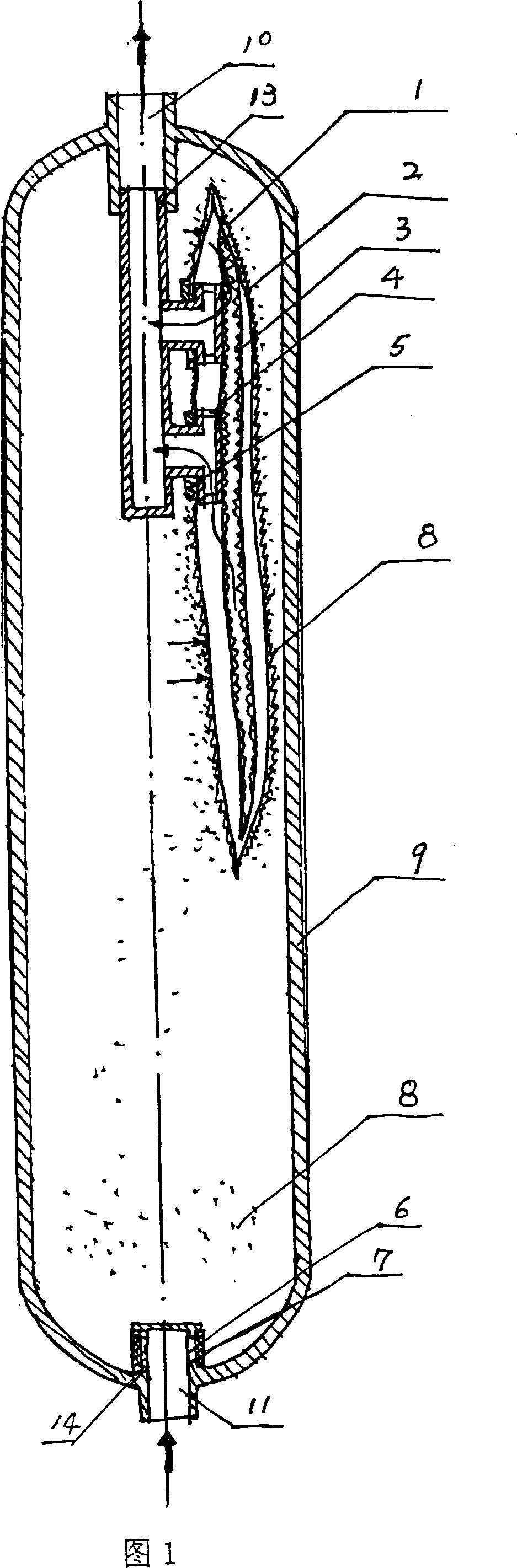

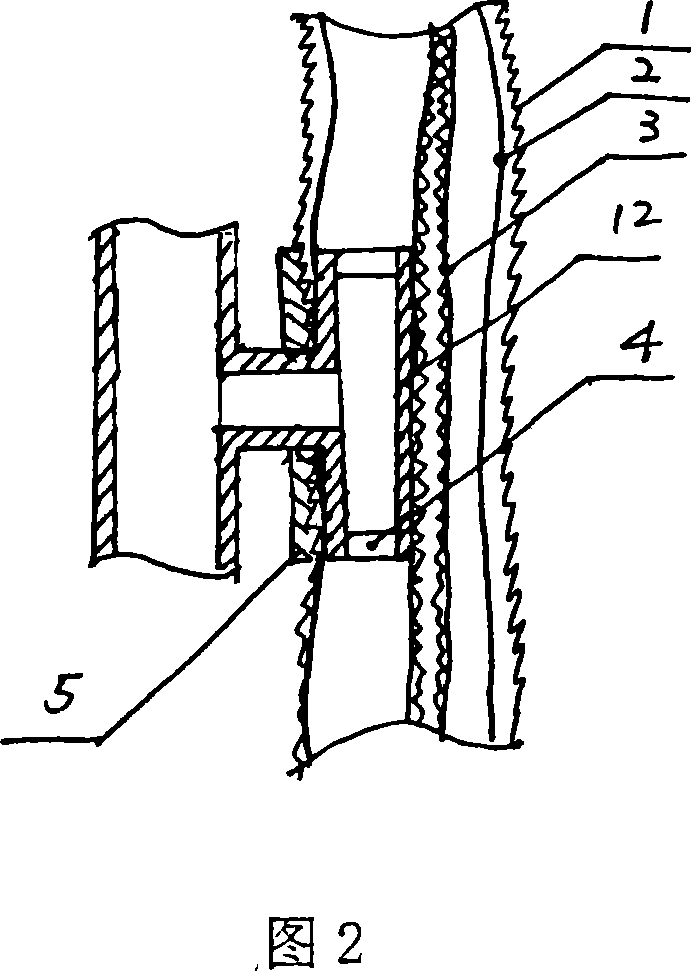

[0015] With reference to accompanying drawing 1,2,3, the structure of the pre-coated micro-osmosis water purifier with filter membrane comprises sealed container 9, water inlet 11, clean water outlet 10, micro-osmosis mechanism, filter material 8. The sealed container 9 is provided with a water inlet 11, the water inlet 11 is equipped with a water inlet check valve, the micro-osmotic mechanism is installed in the sealed container 9, the filter material 8 is installed in the sealed container 9 outside the micro-osmotic mechanism, the micro-osmotic mechanism and The clean water outlet is connected.

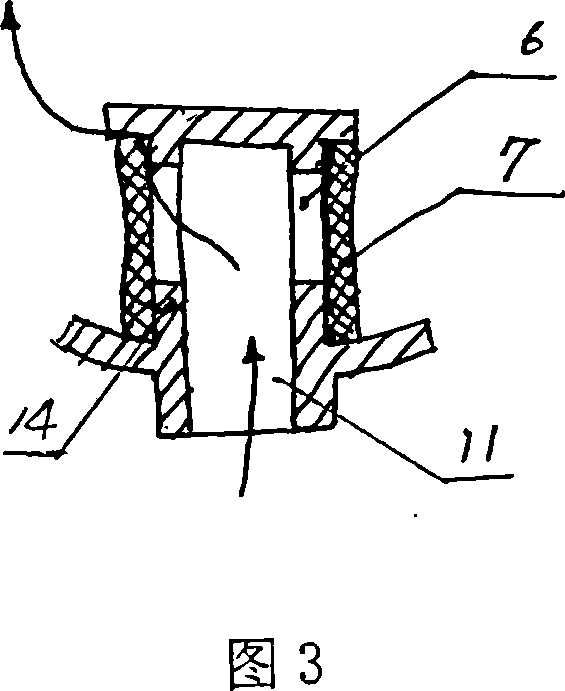

[0016] The water inlet one-way valve is made up of water inlet pipe 14, elastic pipe 7, water outlet 6. The elastic tube 7 is installed outside the water inlet pipe 14. There is a boss on the top of the water inlet pipe 14 to prevent the elastic tube 7 from moving up and down. Tightly wrap the outer wall of the water inlet pipe 14. When water enters the water inlet pipe 14, the wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap