Toughened glass mirror crack sandwich glass and its process

A tempered glass mirror and laminated glass technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem of not being able to make cracks, to ensure product quality, broaden the market, and have a wide range of uses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, specific embodiments of the present invention will be introduced.

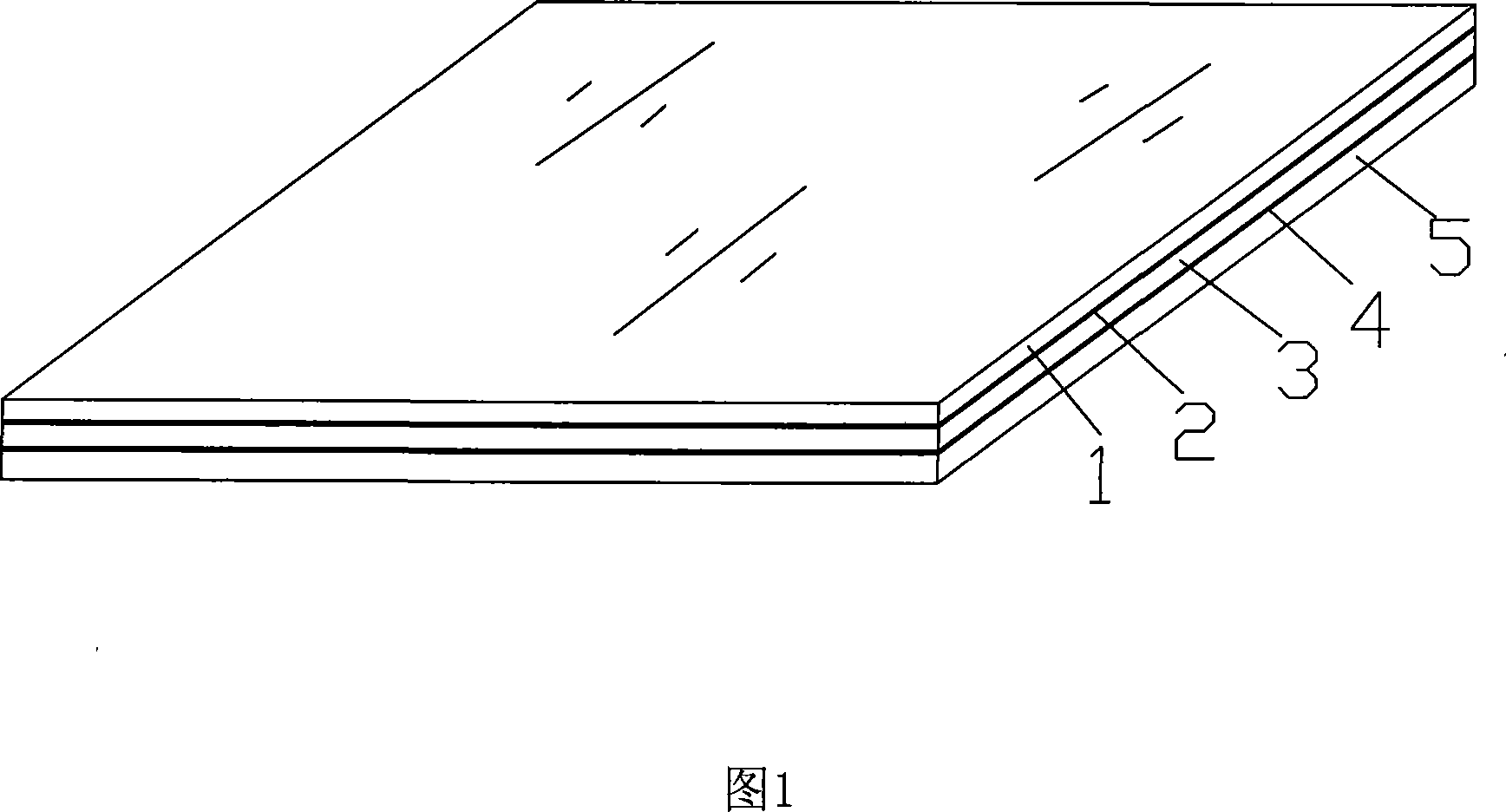

[0025] The cracked laminated glass for tempered glass mirror of the present invention, as shown in Figure 1, its structure comprises, from top to bottom, an ordinary transparent glass surface layer (1), an upper PVC film layer (2), a tempered glass mirror layer (3), The lower film layer (4), the ordinary transparent glass bottom layer (5), the upper film layer (2) bonds the ordinary transparent glass surface layer (1) and the toughened glass mirror layer (3) up and down, and the lower film layer (4) will toughen The glass mirror layer (3) is bonded up and down with the ordinary transparent glass bottom layer (5) to realize the integrated structure of the tempered glass mirror cracked laminated glass.

[0026] The ordinary transparent glass surface layer (1) and the ordinary transparent glass bottom layer (2) refer to ordinary float glass.

[0027] The toughened glass mirror layer (3) has a struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com