Production of organic fertilizer

An organic fertilizer and material technology, applied in the field of organic fertilizer preparation, can solve the problems of difficult temperature rise of materials, multiple processes, and long production time, etc., and achieve the effects of reduced production costs, difficult handling, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

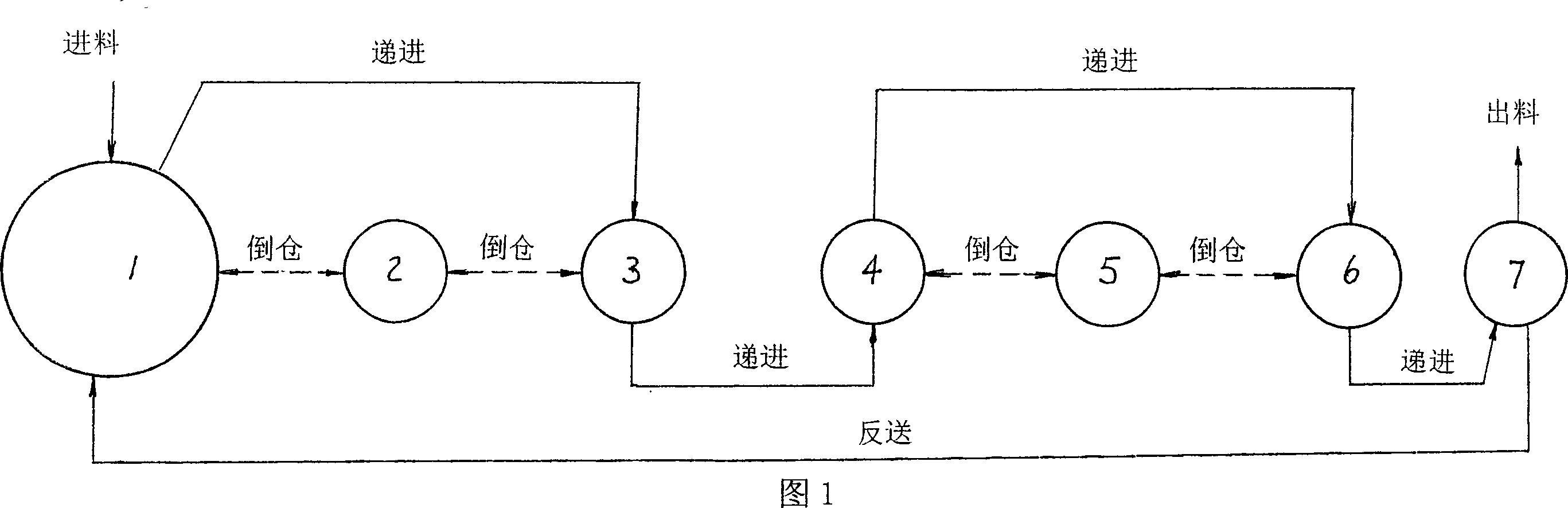

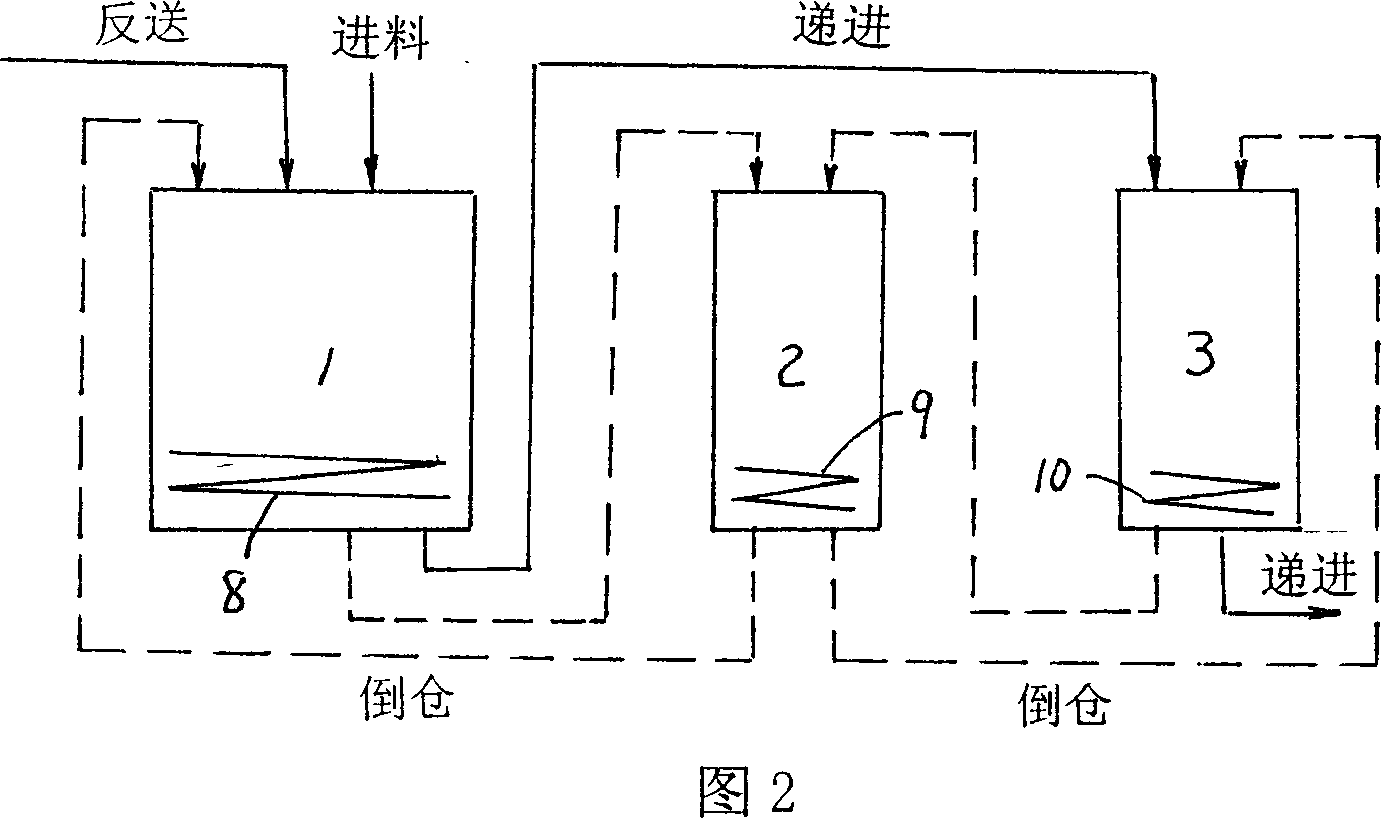

[0038] Embodiment 1, as Fig. 1 is the process route schematic diagram of the present invention method, shows inoculation bin 1 in the figure, two turnover bins 2,5, three progressive bins 3,4,6, discharge bin 7; 2. Hot water coil heaters 8, 9, 10, etc. are installed at the bottom of each bin for heating when moving materials from each bin. The production cycle is 24 hours. Before starting work, according to the process of the present invention, the inoculation bin 1, the first progressive bin 3, the second progressive bin 4, and the third progressive bin 6 are gradually filled with prescribed materials; the turnover bins 2 and 5 are empty of. In the inoculation bin 1, the masterbatch (the anaerobic activated sludge accumulated in the sewage treatment plant is used in this embodiment) is loaded at one time as the strain, and the masterbatch is considered by 5 times the weight of the raw material. After the system runs, only Just add the raw material, no need to add any foreig...

Embodiment 2

[0046] Embodiment 2 is another kind of process (reverse delivery) route of the inventive method, basically identical with embodiment 1, difference is: in described step (3) discharging, the material in the discharge bin 7 is sent out When, retain part of the material (mature bacterial classification) in the described discharge bin 7, send out the material other than the reserved material for separation, and send the described reserved material back into the described inoculation bin 1; Circulate the supplementary masterbatch returned inside to ensure that there is a sufficient number of bacteria in the inoculation bin 1;

[0047] For example, taking the production of 30 tons of organic fertilizer per day as an example, the masterbatch is considered to be 4 times the weight of the raw material. Step (1) When charging, keep 114 tons of masterbatch in the inoculation bin 1, add 6 tons of part of the material returned from the discharge bin 7, then the total amount of masterbatch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com