Method for skipping biomass energy power plant system

A technology for power plants and biomass, applied in the direction of combustion methods, fuel supply, conveyor objects, etc., can solve the problems of material return, reduce the output of the bucket elevator, and easy to burn, so as to improve the use efficiency and increase the lifting angle , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

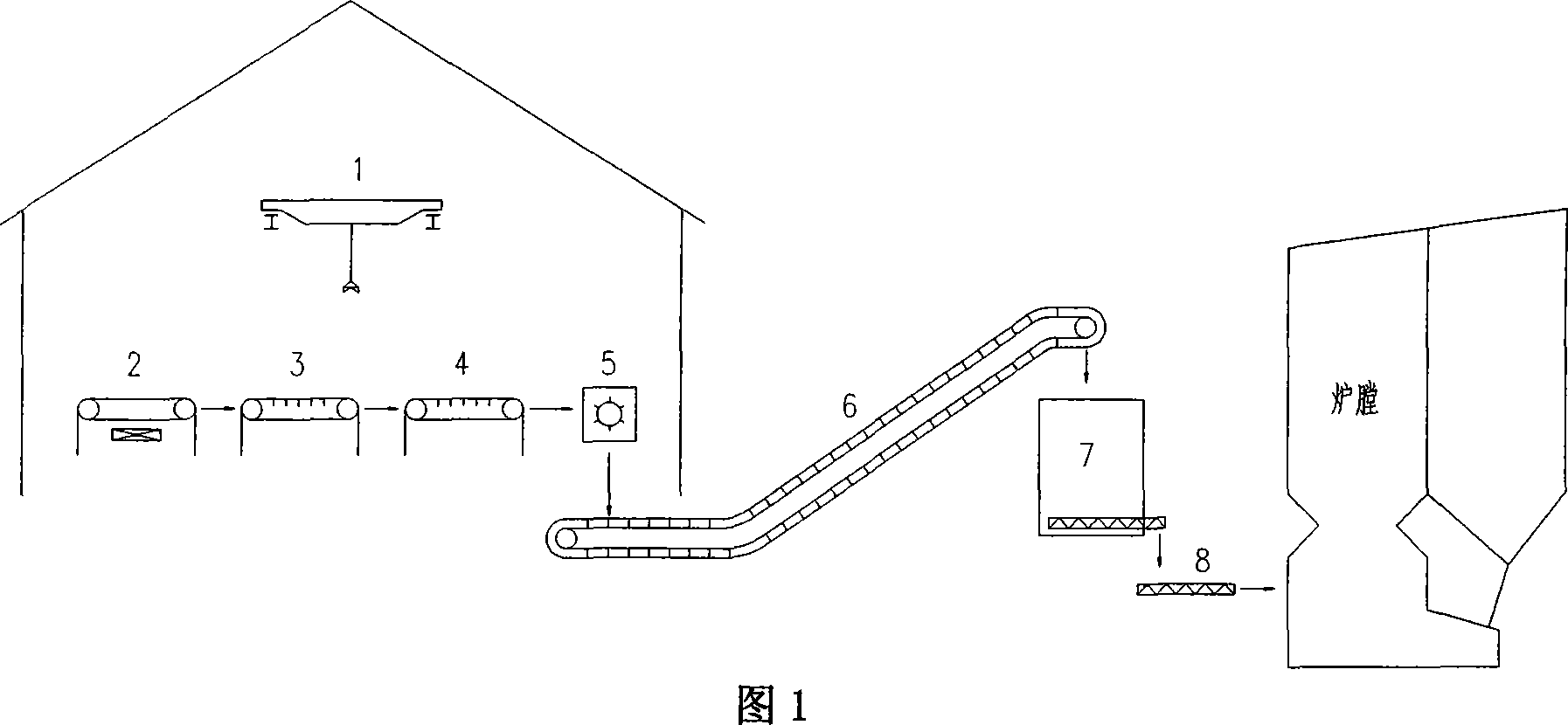

[0042] Straw bale grab crane 1: A double-girder bridge crane with a span of 31.5m and a lifting capacity of 12.5t is selected, equipped with an electro-hydraulic straw bale clamp.

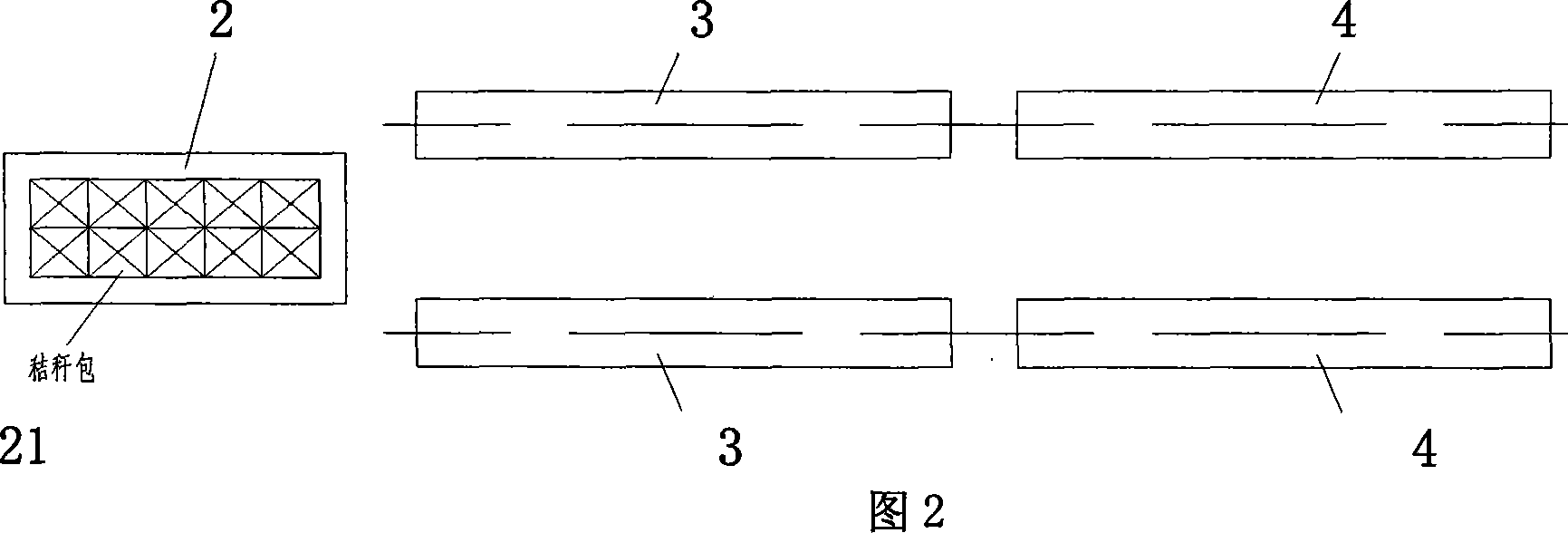

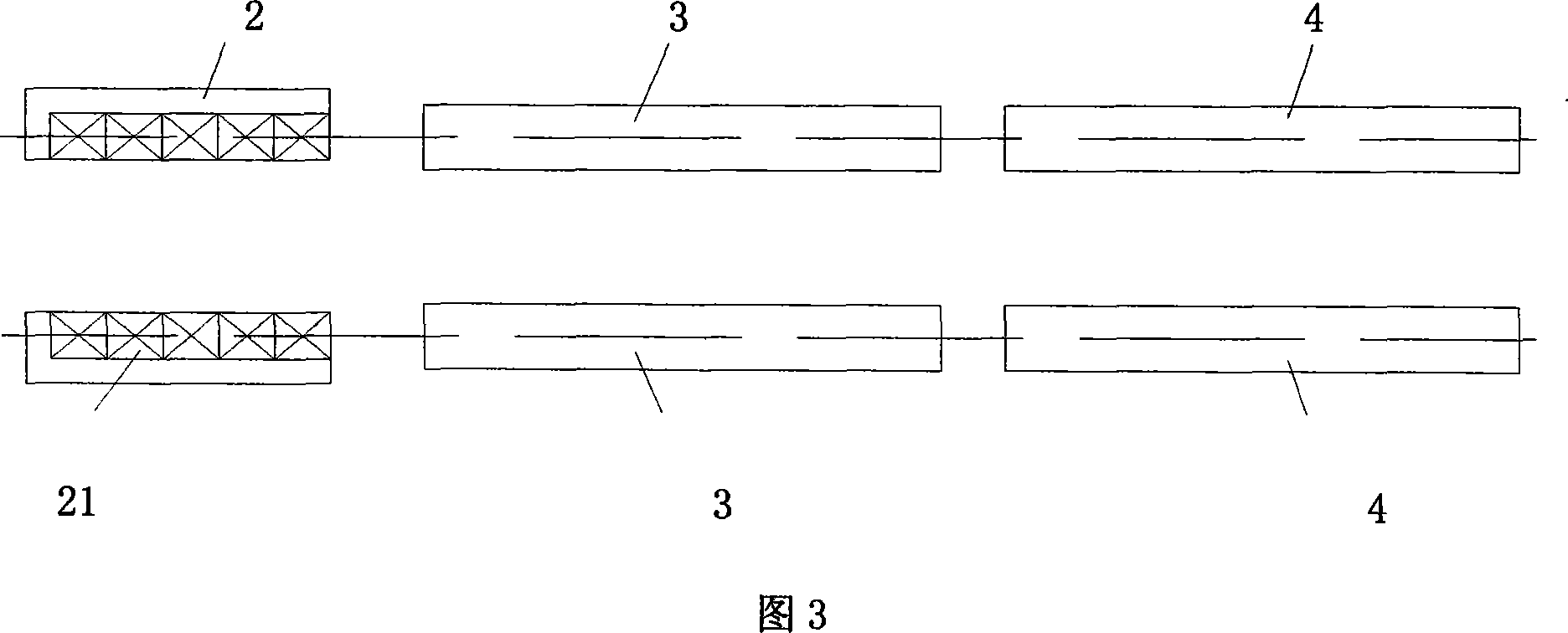

[0043] Subcontracting platform 2: The subcontracting platform adopts two chain conveyors as a group, each with a length of 11m and a width of 2.4m. The chain plate platform is separated and connected with the subsequent chain plate conveyor coaxially.

[0044] The first chain conveyor 3 and the second chain conveyor 4: each chain conveyor has a length of 11m and a width of 1.2m, and is driven by sprockets and chains.

[0045] Straw Crusher 5: Straw Crusher is single-row and one-way bale feeding, the main source materials of straw bales are wheat straw and rice straw, bale density: 250kg / m 3 , Package weight: 380kg. After the straw bales are broken, the output length is 30mm-50mm. Single output: 12.5t / h.

[0046]Corrugated sidewall belt conveyor 6: DJII type corrugated sidewall belt conveyor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com