Need in-degree device and use in asphalt need in-degree determination

A technology for penetration and bitumen, applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of large deviation of measurement results, insufficient and incomplete temperature conditioning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

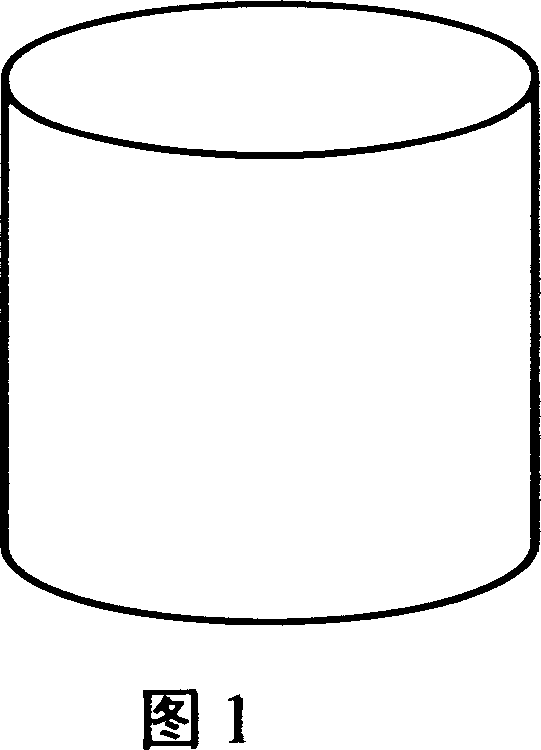

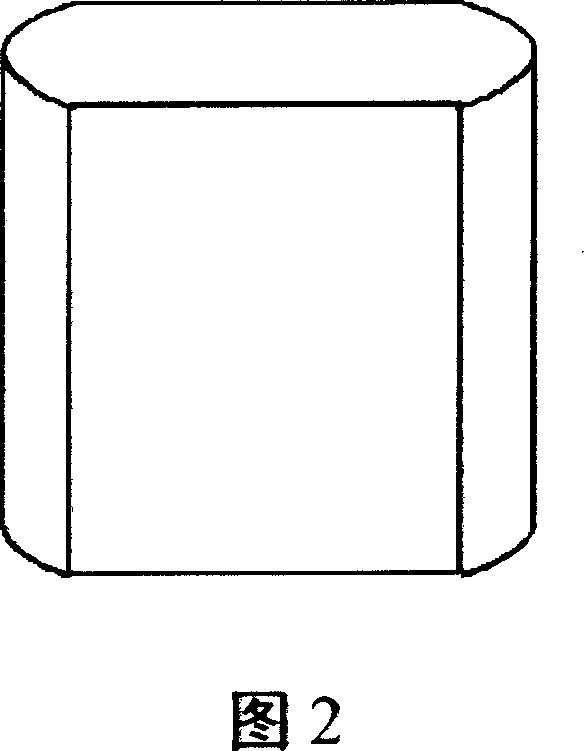

[0028] Penetration at 25°C is used as the grading index for most asphalt products, and it is a must for almost every asphalt sample. The main dimensions of the improved penetration dish used in this embodiment are: cylinder outer diameter D 55mm, cylinder height 35mm, bow height h: diameter D=0.18.

[0029]In this example, straight-run asphalt, SBS modified asphalt and modified asphalt samples made by adding various chemical modifiers were selected, which were prepared by different processes, and the standard dish and the improved dish were used as experimental molds respectively. Their 25°C needle penetrations were measured. Wherein, the measurement process of the standard dish is carried out according to the standard method GB / T4509-1998, wherein the cooling time of cooling is 1 hour, and the constant temperature time is 1 hour; adopting the improved dish of the present invention, except that the cooling time of cooling and the constant temperature time are respectively high...

Embodiment 2

[0033] Measure the penetration value of the same sample at multiple different temperatures, and calculate the correlation coefficient R of the penetration result through linear regression, and measure the accuracy of the penetration measurement result by the degree to which R meets the corresponding specified value. In recent years, mathematical statistics methods have been introduced to verify the accuracy of needle penetration test results. In this example, when a standard dish is used, the measurement process is carried out according to the standard method GB / T 4509-1998, wherein the cooling time is 1 hour, and the constant temperature time is 1 hour; the improved needle penetration dish used in this example The main dimensions are: cylinder outer diameter 55mm, cylinder height 35mm, bow height h: diameter D=0.28, except that the cooling time and constant temperature time are shortened by 0.5 hours compared with the standard dish, the rest of the process is also in accordanc...

Embodiment 3

[0036] The main dimensions of the improved penetration dish used in this embodiment are: outer diameter of cylinder D 55mm, cylinder height 35mm, bow height h:diameter D=0.05. The standard dish and the improved dish are used to measure the penetration of asphalt samples, except for the following conditions, other operating conditions and steps are the same as the standard method. Wherein when using the standard dish, the cooling time at room temperature and the constant temperature time in the constant temperature water bath are 1.0 hours; when using the improved dish, the cooling time at room temperature and the constant temperature time in the constant temperature water bath are 0.75 hours , and the measurement results are shown in Table 3.

[0037] sample number

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com