Engine air cleaner

A technology for air purifiers and engines, applied in the direction of electrochemical generators, chemical instruments and methods, electrical components, etc., can solve the problems of increased air turbulence, loss of purification efficiency, unfavorable gas transmission, etc., to improve flow resistance, simplify Manufacturing process, the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

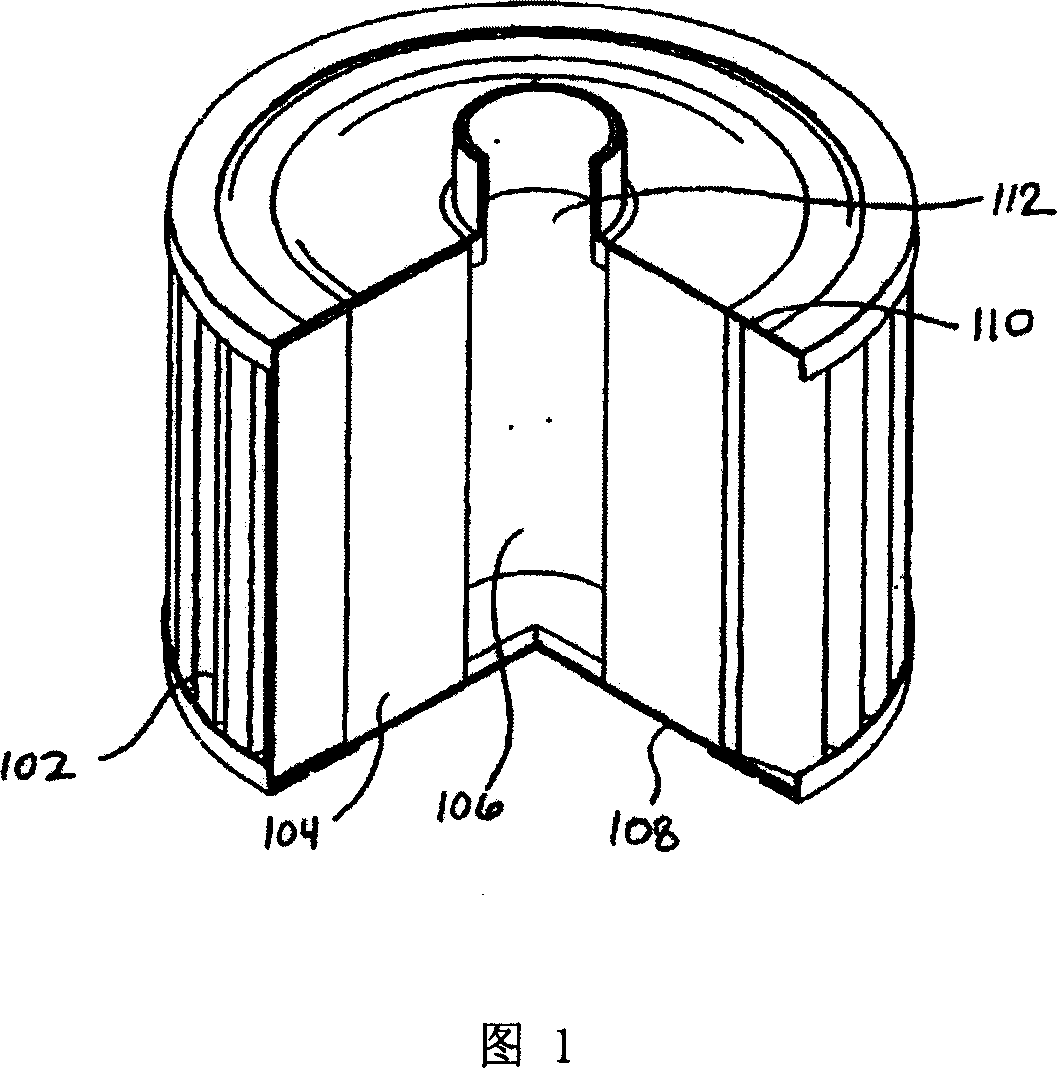

[0045] Fig. 3 shows the embodiment of the engine air purifier of the present invention, and it comprises conical air intake channel 1, hydrophobic polymer film 4, adsorption layer housing 6, the adsorption layer that is located in the adsorption layer housing 6, stainless steel filter screen 7. Conical air outlet channel 9, wherein the adsorption layer includes a plurality of layered monolithic adsorbents 11 arranged at intervals, air flow channels 12, and a plurality of air flow channels arranged alternately in the layered structure The wedge-shaped baffles 15 between the integral adsorbents 11 and the net-shaped adsorption layer support frame 16 fixedly connected with the wedge-shaped baffles 15 . The tapered air inlet channel 1 and the tapered air outlet channel 9 are respectively fixed at both ends of the adsorption layer housing 6 . The hydrophobic polymer film 4 is fixed between the conical air inlet channel 1 and the adsorption layer housing 6 , and the stainless steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com