Multiple bend circuit friction conveying plastic bottle tube heater

A technology for a plastic bottle and a heater, applied in the field of plastic machinery, can solve the problems of long route, low utilization rate of heating electric energy, large energy consumption, etc., and achieve the effect of shortening the heating circuit, high utilization rate of electric heat and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

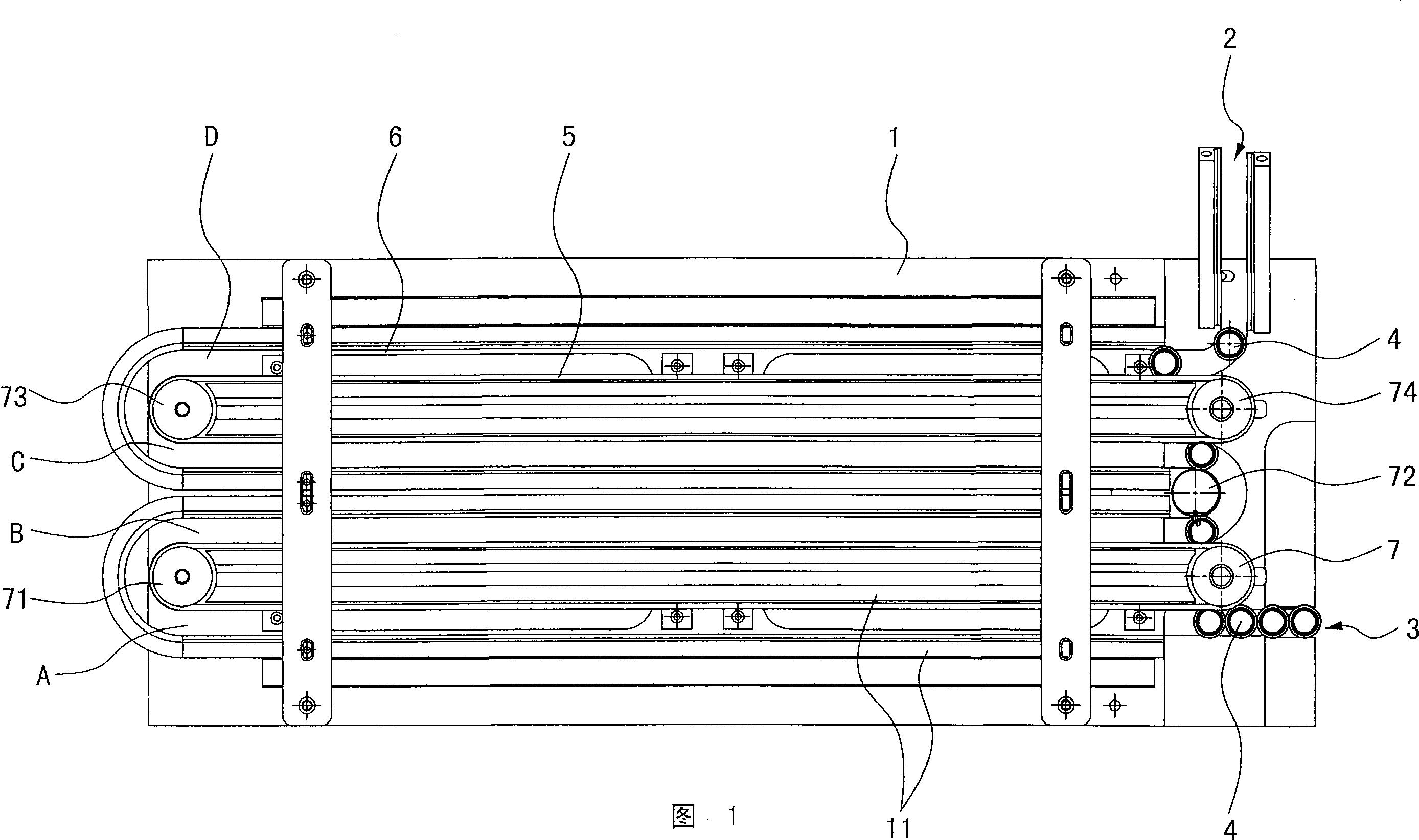

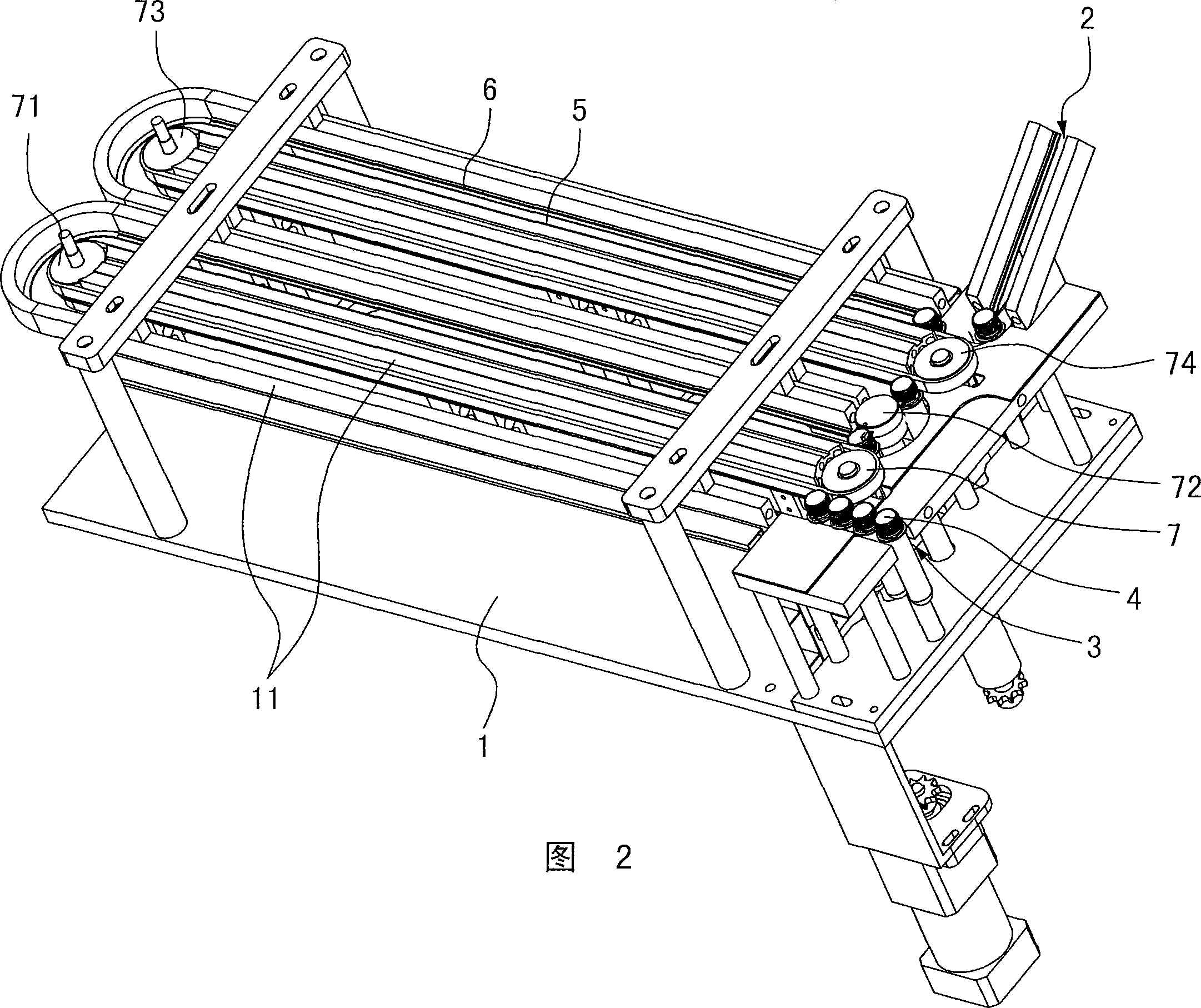

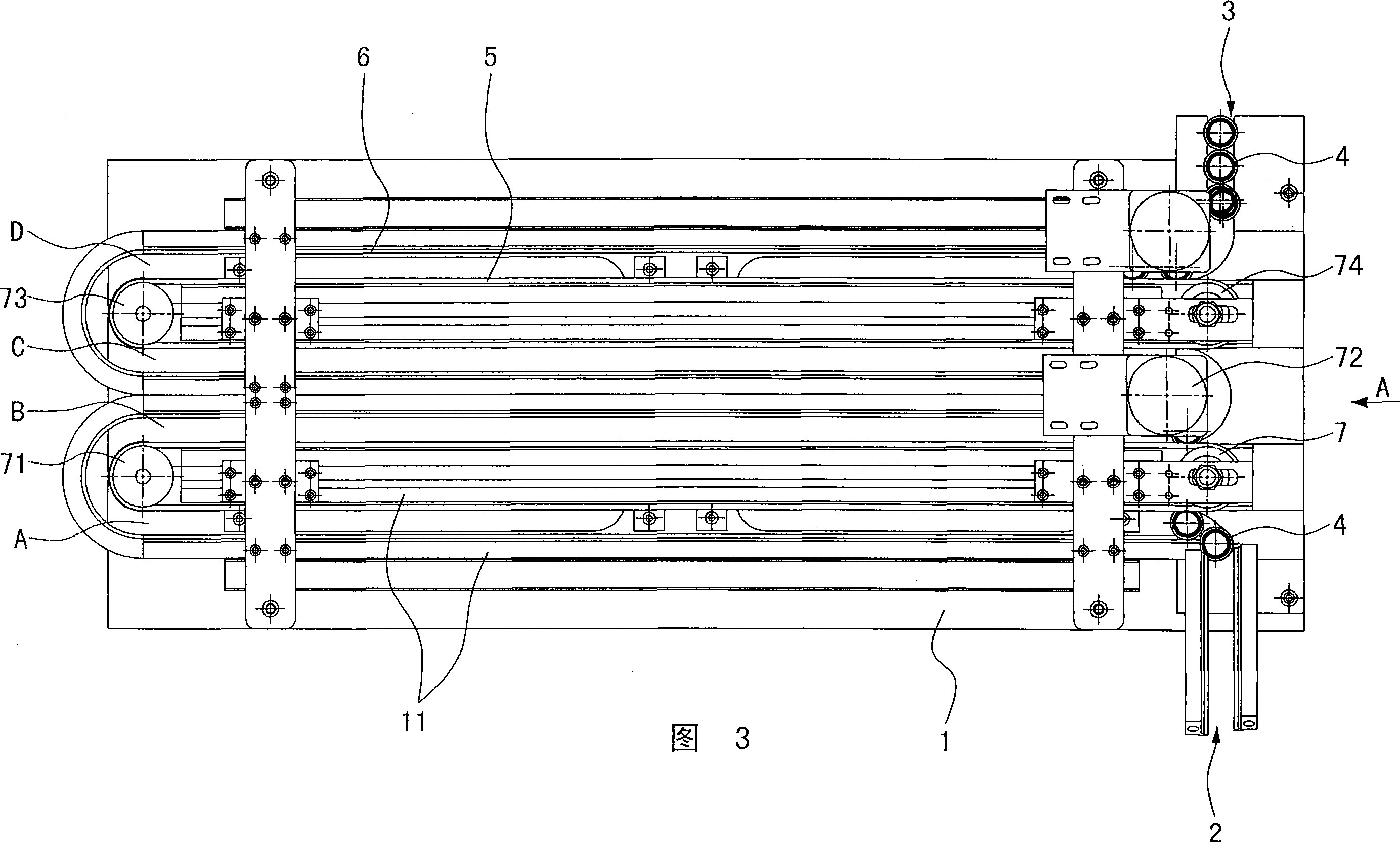

[0016] The invention relates to a multi-curve friction conveying plastic bottle tube heater. As shown in Figures 1-9, there is a heater bracket 1, and a plastic bottle tube conveying mechanism is installed in the support. The conveying mechanism has a conveying heating channel, and a trusteeship is installed in the conveying heating channel. The device and the friction belt, the friction belt is driven by the transmission mechanism, and the electric heating device is installed at the lower part of the bracket corresponding to the conveying heating channel, which is characterized in that the conveying heating channel is at least two multi-curved conveying channels in an S-shaped direction, The S-shaped trend is shown in Figure 1 and Figure 3, which is a ring connected to a ring, and there are 4 lines in the figure, which are divided into A, B, C, and D. The hosting device is a supporting plate 6 or a friction strip 61, the supporting plate 6 is in contact with the baffle plate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com