Preparation method of polyamide/nano montmorillonite masterbatch

A nano-montmorillonite and polyamide technology, applied in the field of composite materials, can solve problems such as difficulty, long period, and impact on composite materials, and achieve the effect of improving tensile strength and bending strength, simple method, and expanding interlayer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

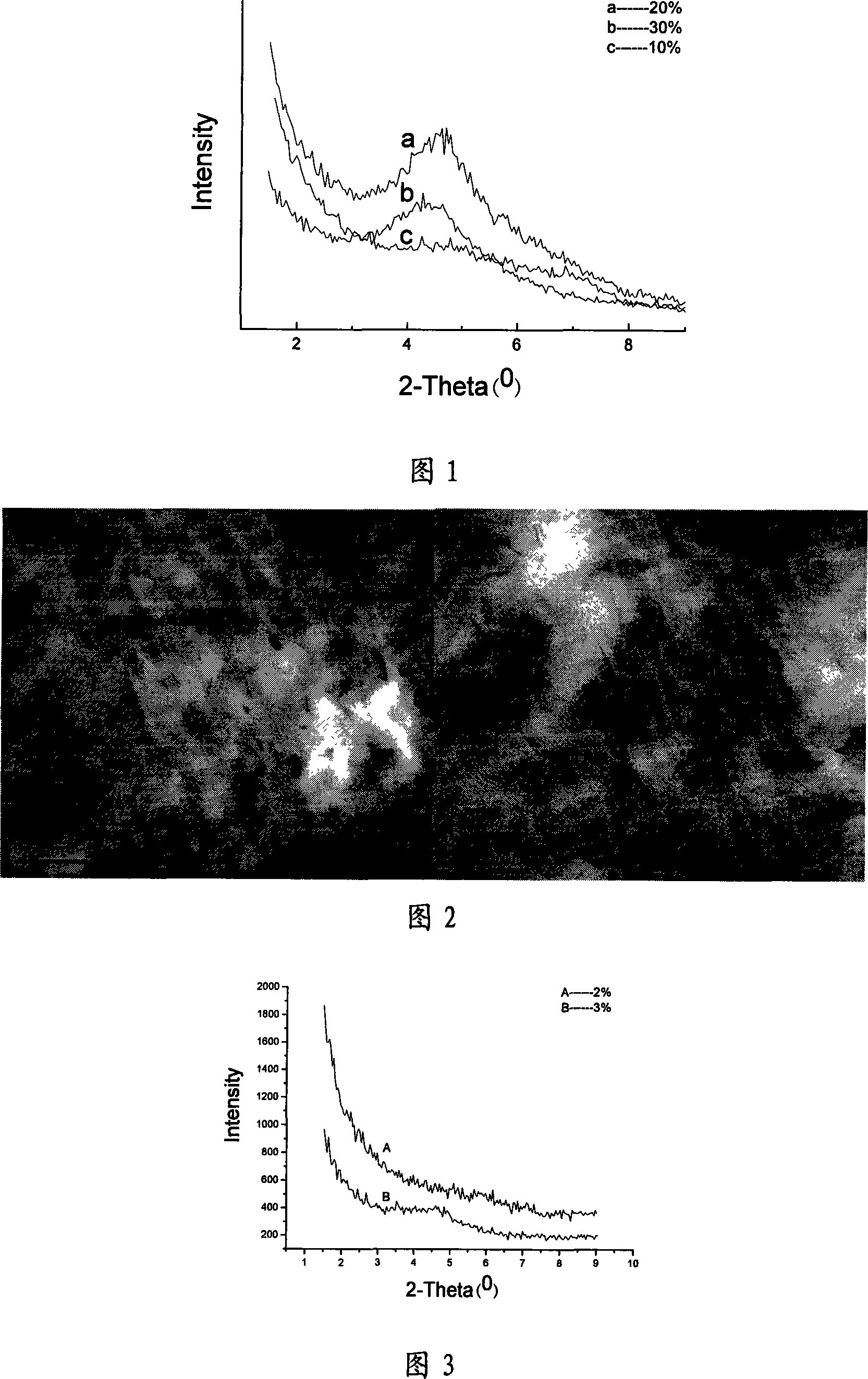

[0028] Purify 10 parts of montmorillonite, 90 parts of deionized water, stir and disperse to obtain montmorillonite slurry, add 90 parts of polyamide 6 to the internal mixer at 220°C, and gradually add montmorillonite after polyamide 6 is completely melted After adding the slurry within 20 minutes, continue to knead in an internal mixer at 220°C for 10 minutes, and then extrude and granulate to obtain a polyamide / montmorillonite masterbatch, that is, a polyamide / nano-montmorillonite masterbatch. The XRD pattern of the masterbatch is shown in Figure 1, and the TEM photo is shown in Figure 2.

Embodiment 2

[0030] Purify 20 parts of montmorillonite, 300 parts of deionized water, stir and disperse to obtain montmorillonite slurry, add 80 parts of polyamide 6 to the internal mixer at 220°C, and gradually add montmorillonite after polyamide 6 is completely melted For slurry, continue mixing at 220°C for 15 minutes after adding within 40 minutes. The polyamide / montmorillonite masterbatch with a montmorillonite content of 20% is obtained through extrusion granulation. The XRD of the masterbatch is shown in Figure 1. Add 10 parts of the masterbatch to 90 parts of pure polyamide 6 resin, extrude and granulate at 230 ° C, and obtain the polyamide / montmorillonite nanocomposite material accordingly, and the (001) diffraction of montmorillonite in its XRD spectrum The peaks all disappeared, see Figure 3.

Embodiment 3

[0032] Purify 15 parts of montmorillonite, 150 parts of deionized water, stir and disperse to obtain montmorillonite slurry, add 85 parts of polyamide 66 to the internal mixer at 260 °C, after polyamide 66 is completely melted, gradually add montmorillonite After adding the slurry within 30 minutes, continue to knead at 220°C for 10 minutes, extrude and granulate to obtain a polyamide / montmorillonite masterbatch with a montmorillonite content of 15%. The XRD pattern of the masterbatch is shown in Figure 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com