Secondary puffing technical method of textile materials

A technology of secondary puffing and process method, used in textile and papermaking, textile material processing, textile and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

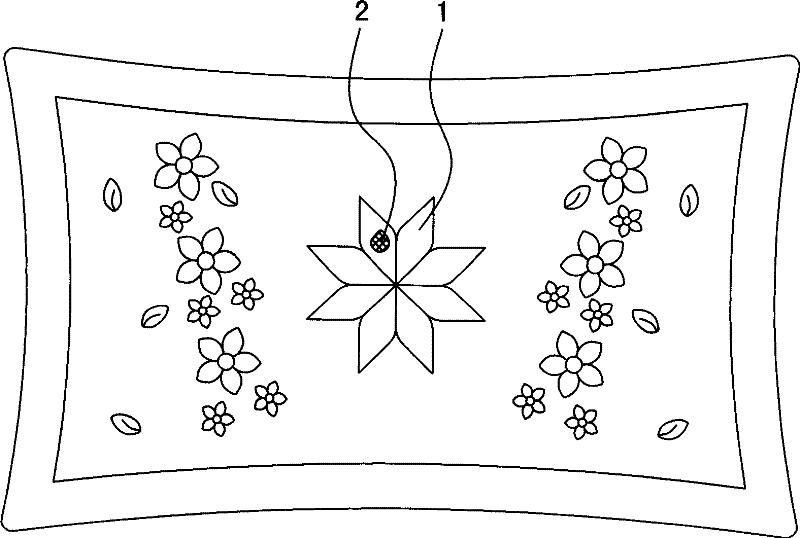

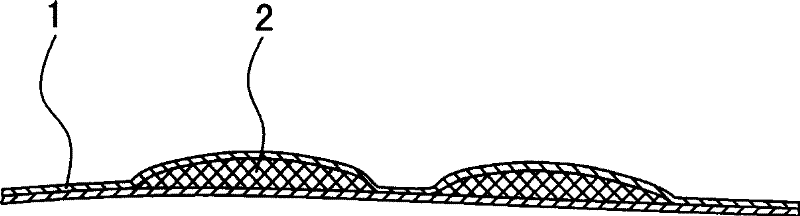

[0012] The present invention relates to the secondary puffing process of textiles, and its main technical features are:

[0013] ①. Choose more than two (multiple) fiber materials for weaving. The fiber materials can be natural plant fibers or chemical synthetic fibers, such as cotton, silk, hemp, wool, acrylic, etc. The selected fiber materials require different shrinkage rates and thicknesses. Materials with different specifications and different coloring degrees, according to the pre-designed digital jacquard program (all fabrics must be designed), automatically select the weft by the loom and electronic digital easy weaving into rough fabrics with concave and convex patterns, achieving the first puffing , the puffing is executed depending on the selection of materials and different materials to achieve the result;

[0014] ②. Bleach and finish the crude fabric with polyester and cotton two-in-one softener and fabric bulking agent to meet the needs of the second puffing; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com