Preionization igniting device based atmosphere pressure discharging cold plasma generators

A technology of cold plasma and ignition device, applied in the direction of plasma, discharge tube, electrical components, etc., which can solve the problems of high breakdown electric field, limited use of plasma technology, and high cost of rare gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

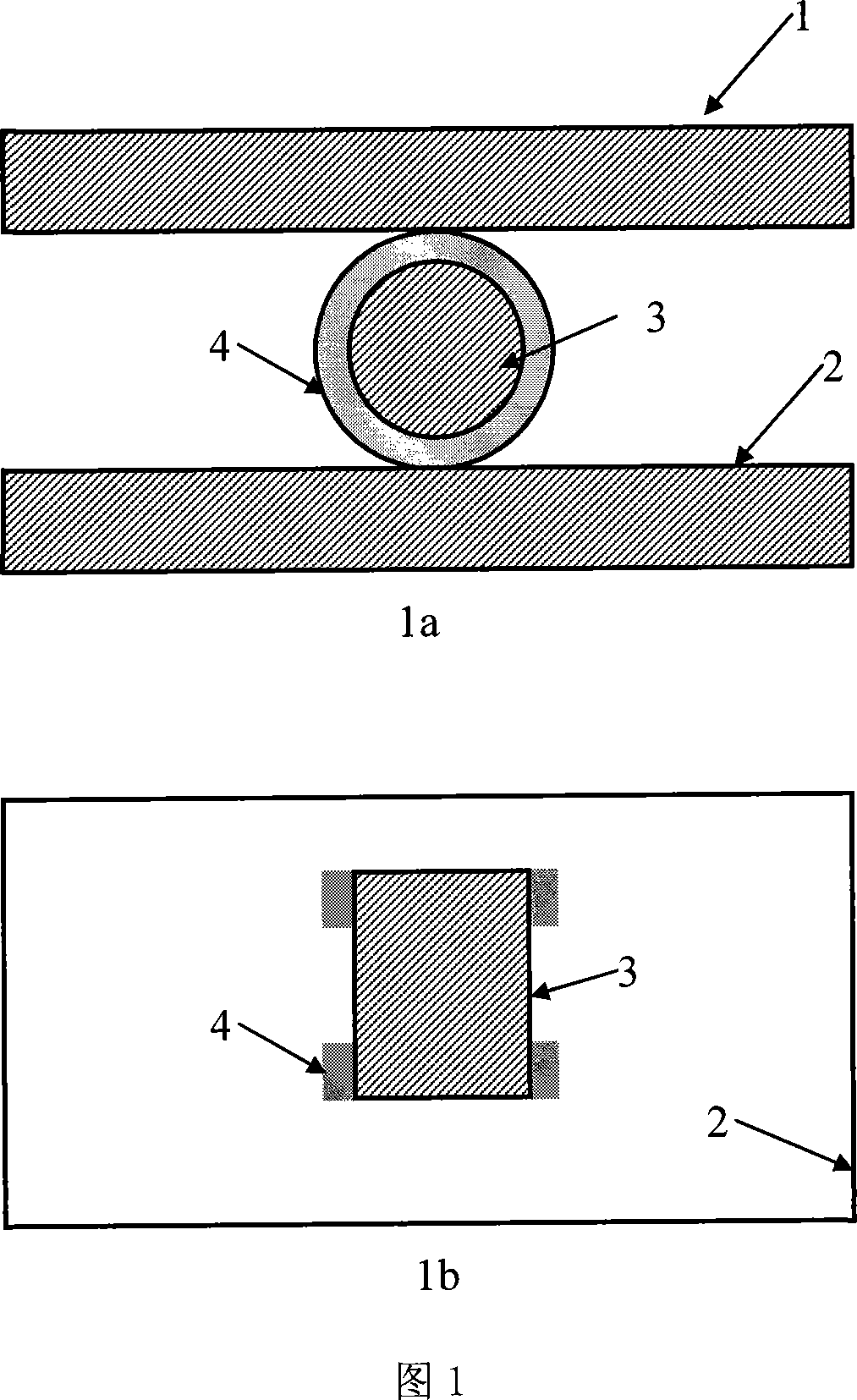

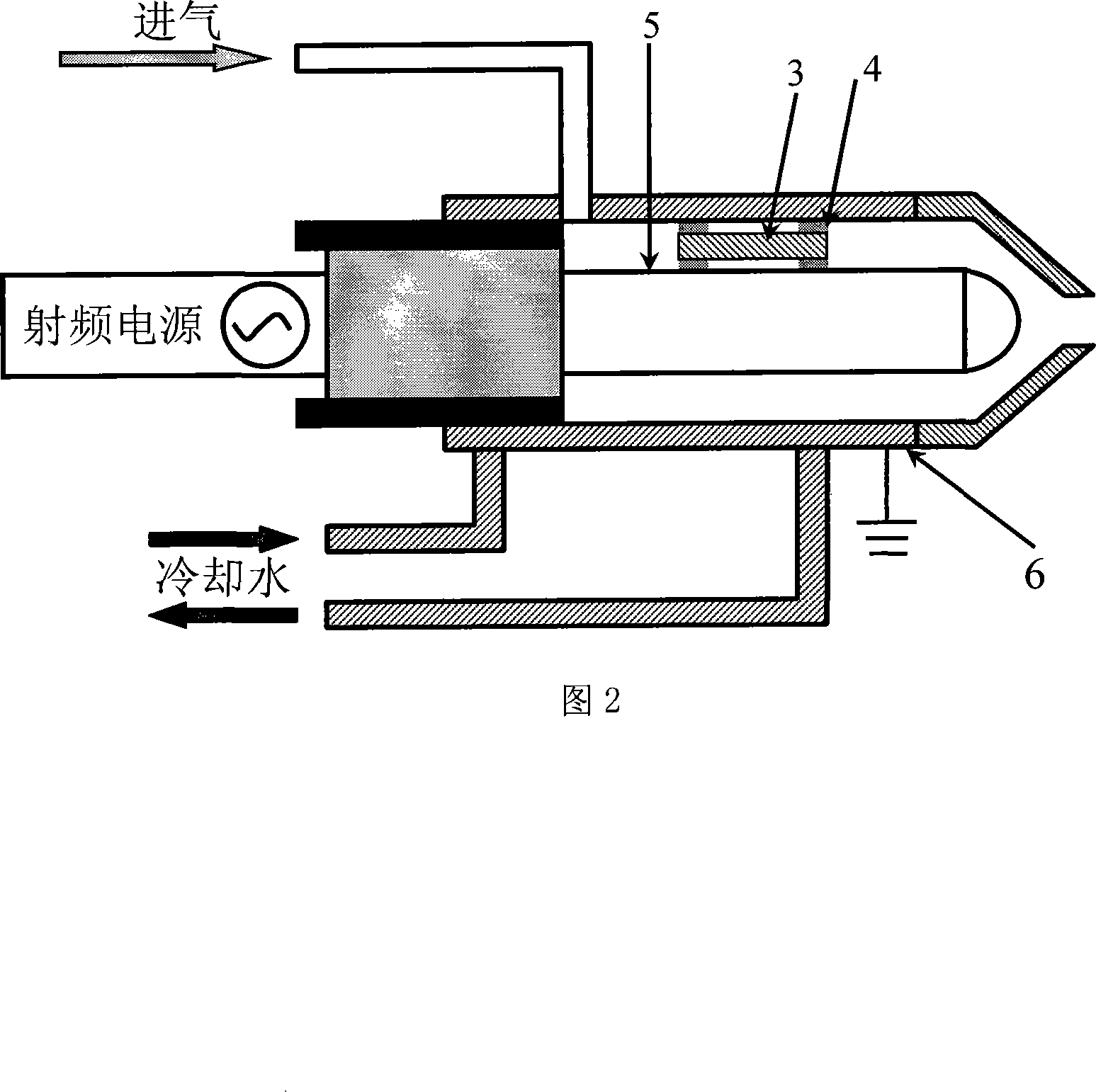

[0018] The present invention adopts in the cold plasma generator as shown in Fig. 1, 2, through the pre-ionization effect of the third electrode to the working gas, seed electrons are provided for the formation of discharge between the radio frequency electrode and the ground electrode, thereby realizing the When the voltage is relatively large and the breakdown voltage is low, the direct breakdown discharge of nitrogen, air, oxygen and other gases that are difficult to break down directly under the original atmospheric pressure can be directly realized. The third pole can adopt a floating potential or connect to a high-voltage power supply, both of which can achieve the purpose of pre-ionization of the working gas.

[0019] Figure 1 is a schematic diagram of a flat-panel plasma generator with a pre-ionization ignition device. Wherein, 1 is a radio frequency electrode, 2 is a ground electrode, 3 is a third electrode for pre-ionization, and 4 is an insulating material separatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com