Therapeutic formulations of keratinocyte growth factor

一种生长因子、角质的技术,应用在成纤维细胞生长因子、生长因子/诱导因子、非有效成分的医用配制品等方向,能够解决未被解决等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Liquid formulation of KGF

[0076] Product stability, shelf-life and biological activity are important aspects for any composition of therapeutic efficacy. Designing and formulating compositions that are stable when stored at recommended storage temperatures for extended periods of time, yet retain significant biological activity, are key elements of pharmaceutical compositions.

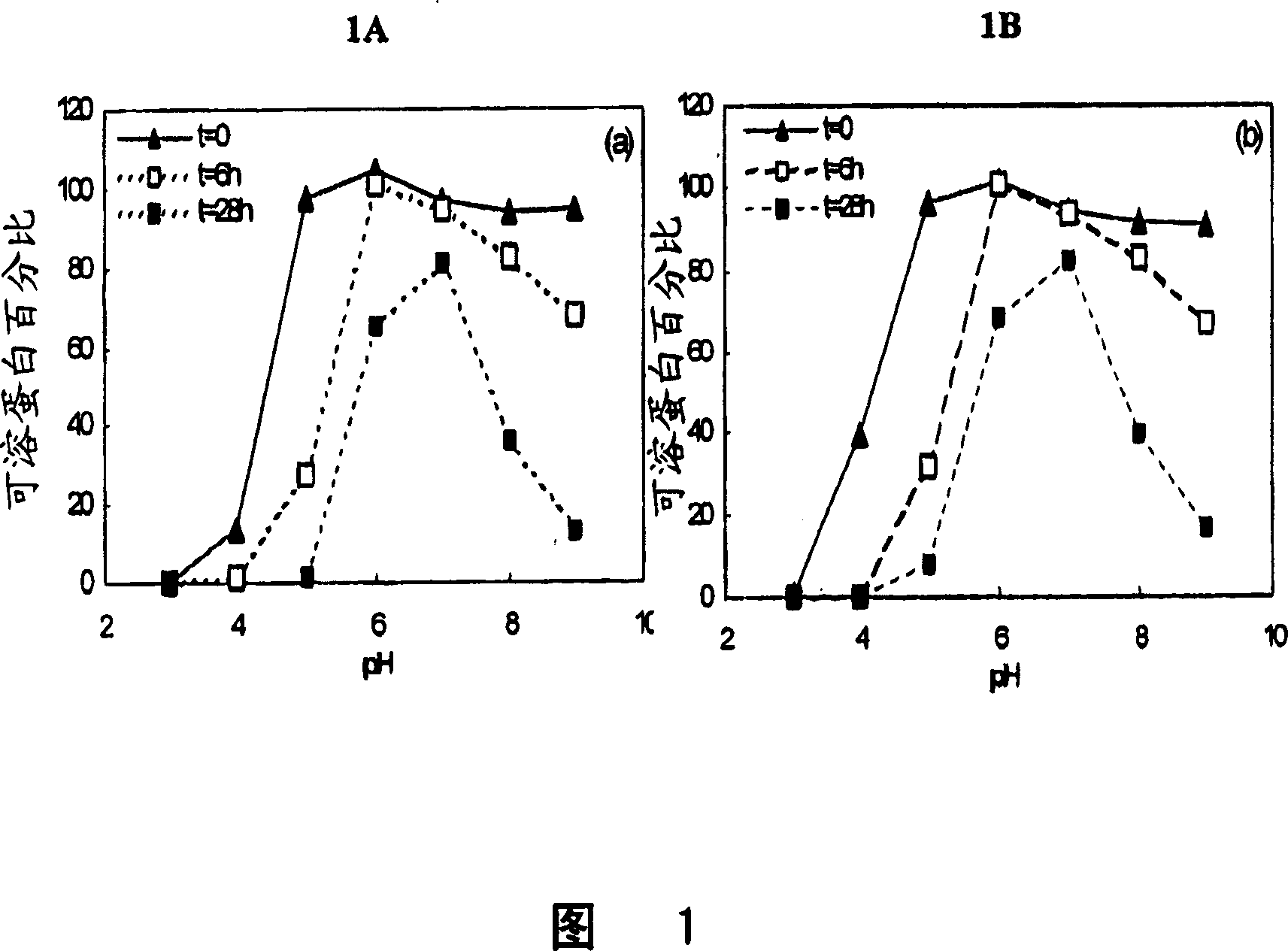

[0077] In previous experiments, liquid formulations of KGF showed significant aggregation and subsequent protein loss at elevated temperature (37°C). In order to determine the pH that provided the greatest stability for the KGF composition, the pH of the liquid formulation of keratinocyte growth factor was tested over a pH range of 3.0 to 9.0.

[0078]In the following experiments, for example, the KGF used in Examples 1-3 was the ΔN23 KGF molecule. The pH of the solution was adjusted using concentrated HCl or NaOH. Samples of the KGF formulation (0.5 mg / ml, 10 mM buffer,...

Embodiment 2

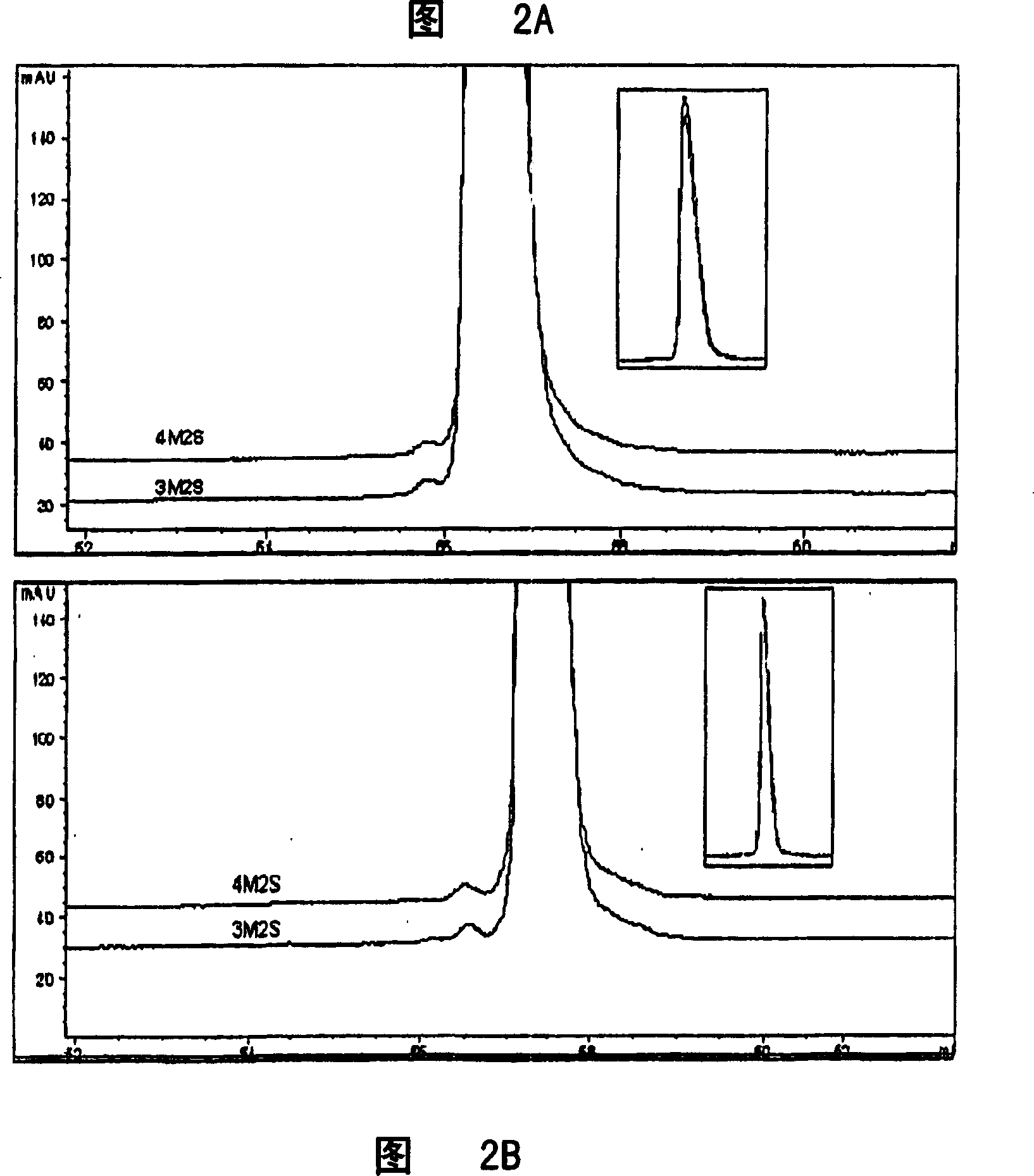

[0084] Formulation of KGF Compositions for Lyophilization

[0085] In order to develop a more stable KGF composition, it was decided to formulate KGF as a lyophilized product. Previous efforts to formulate lyophilized KGF compositions involved manipulating the reconstitution solution, resulting in compositions that produced less protein aggregation depending on the composition of the reconstitution solution [Zhang et al., Pharm.Res. 12:1447-52( 1995)]. However, any aggregation seen during remodeling was difficult or impossible to reverse in this earlier study.

[0086] This example describes lyophilization of proteins in solution that will prevent aggregation upon reconstitution independently of the reconstitution solution, eliminating the need for conventional reconstitution solutions.

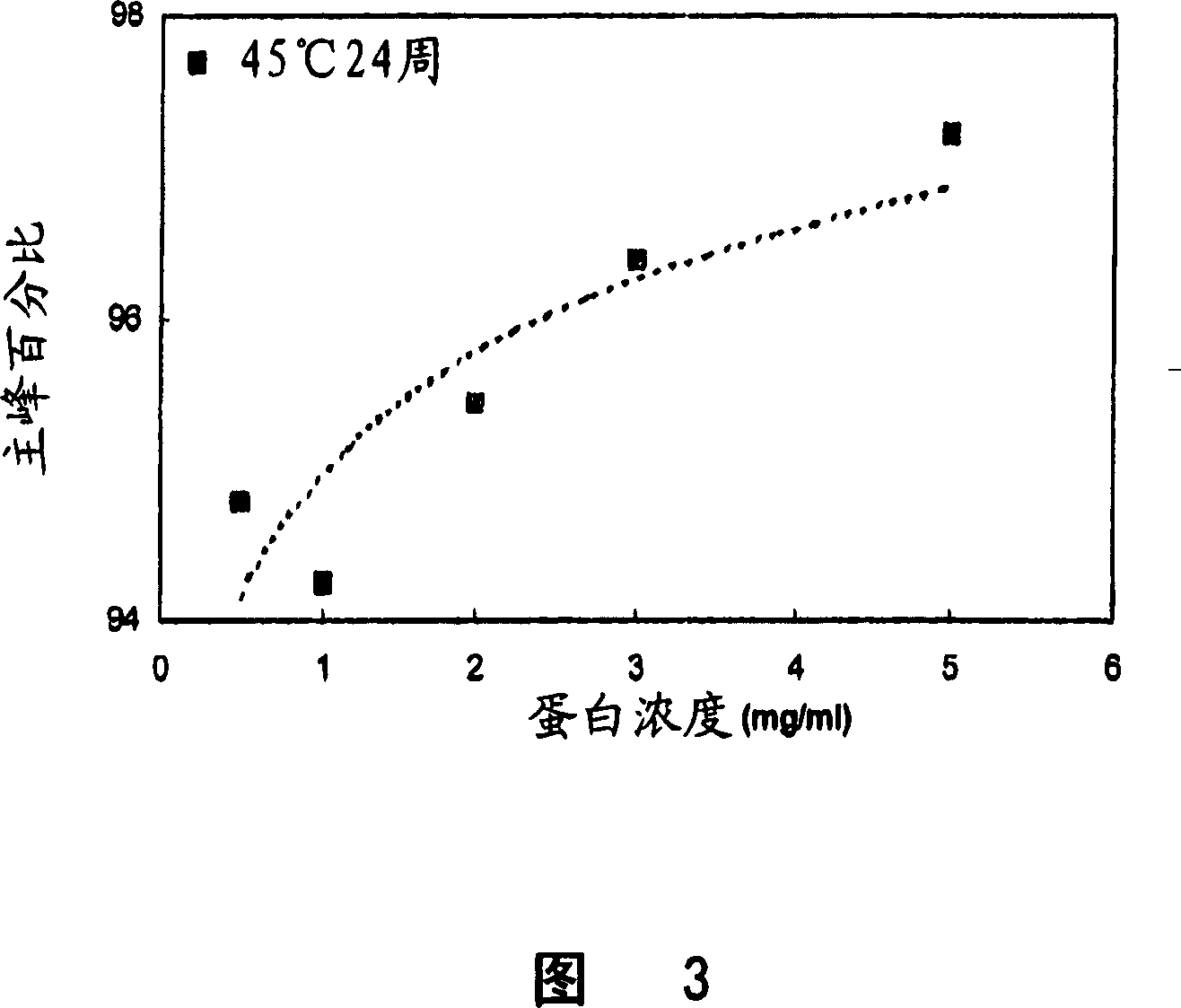

[0087] In order to determine the composition of a stable lyophilized formulation, KGF was lyophilized under altered conditions, such as ΔN23 KGF, varying parameters such as pH, ...

Embodiment 3

[0114] Bioassay of reconstituted KGF preparations

[0115] One of the factors in the formulation of pharmaceutically effective products is the need for highly biologically active target proteins.

[0116] The biological activity of KGF, such as ΔN23 KGF preparations was tested using 32D KECA clone 16 cells, which are IL-3 dependent murine primary lymphocytes that proliferate in the presence of KGF, similar to 32D clone 3 cells (ATCC #CRL-11346) , is a useful proliferation assay system as described in Hsu et al., 1999 Biochemistry, 38, 2523-2534.

[0117] 32D clone 16 cells at 37°C and 5.5% CO 2 Maintained in growth medium [RPMI, fetal bovine serum (10%) (Hyclone, Logan, UT), glutamine (1%) (Gibco / Invitrogen, Carlsbad, CA, ), geneticin (2%) (Gibco ) and mouse IL-3 (12ng / mL) (Biosource International, Camarillo, CA)]. Sample KGF preparations or reference standards (in - ΔN23 KGF) was reconstituted to about 25 ng / mL by freeze-drying at 70°C. Serial dilutions were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com