Light polarizing products and method of making same

A polarizing and product technology, applied in the field of polarizing products and its preparation, to achieve the effects of good mechanical integrity, good heat resistance, and high polarization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

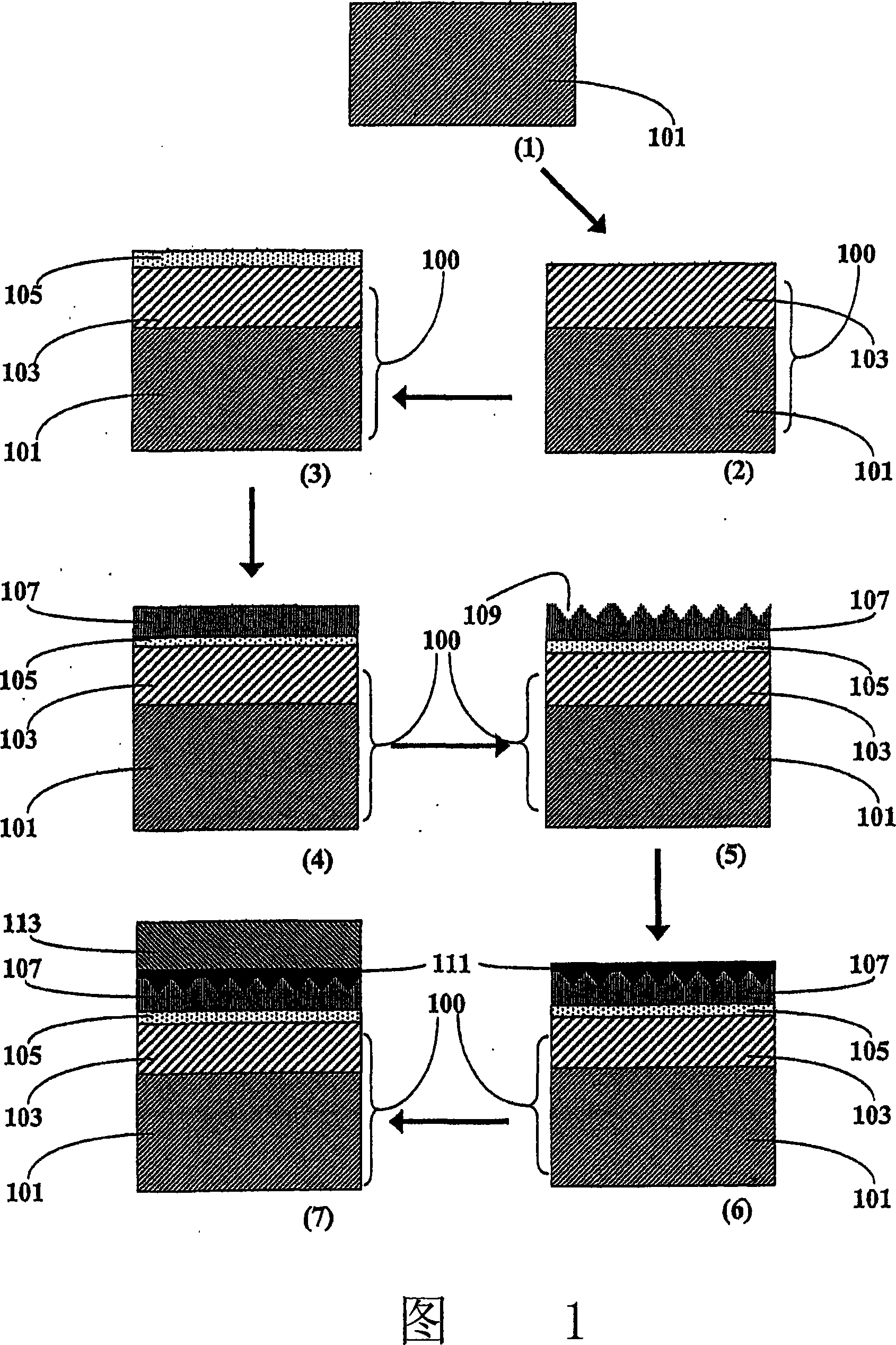

Method used

Image

Examples

Embodiment 1

[0130] Embodiment 1 (the present invention):

[0131] Polyurethane-urea plastic lenses sold under the trade name NXT(R) from Intercast Europe SPA were coated with HI-GARD(R) 1080 coating according to the resin manufacturer's recommended guidelines. The final hard coat thickness is 2-3 μm. After the surface is cleaned, a thin layer of chromium is used as an adhesion layer, deposited on top of the hard coat, and then 100nm thick SiO 2 The coating is vacuum deposited.

[0132] The coated substrate is then brushed with an appropriately sized wheel made of polyurethane foam. The wheel is saturated with abrasive slurry to form parallel microgrooves in the surface of the coated lens.

[0133] The abrasive slurry used is a mixture of water and micron sized zirconia particles to provide a gentle abrasive brushing. Wheel speed is 340rpm, pressure is about 40g / cm 2 , applied for about 5 seconds. The microgrooved lenses were then rinsed with deionized water and dried at 50°C for 2 m...

Embodiment 2

[0144] Embodiment 2 (comparative example):

[0145] Repeat the same process as in Example 1, except omit the adhesive layer and SiO 2 layer. Grooves were therefore made directly on the hardcoat HI-GARD(R) 1080.

[0146] Polarization efficiency was 98% after dye deposition and 96% after the entire process. During water treatments such as aluminum chloride treatment or silane treatment, some lenses delaminate, resulting in unacceptable aesthetic defects. None of these lenses survived the boiling water test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com