Method and device for creating a pattern on dyed materials using a water jet treatment

A cloth, jet technology, applied in the direction of thorn pattern, textile material processing, local processing of textile materials, etc., can solve the problem of low-quality pattern generation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below with reference to accompanying drawing according to the embodiment of the present invention, shows in the figure:

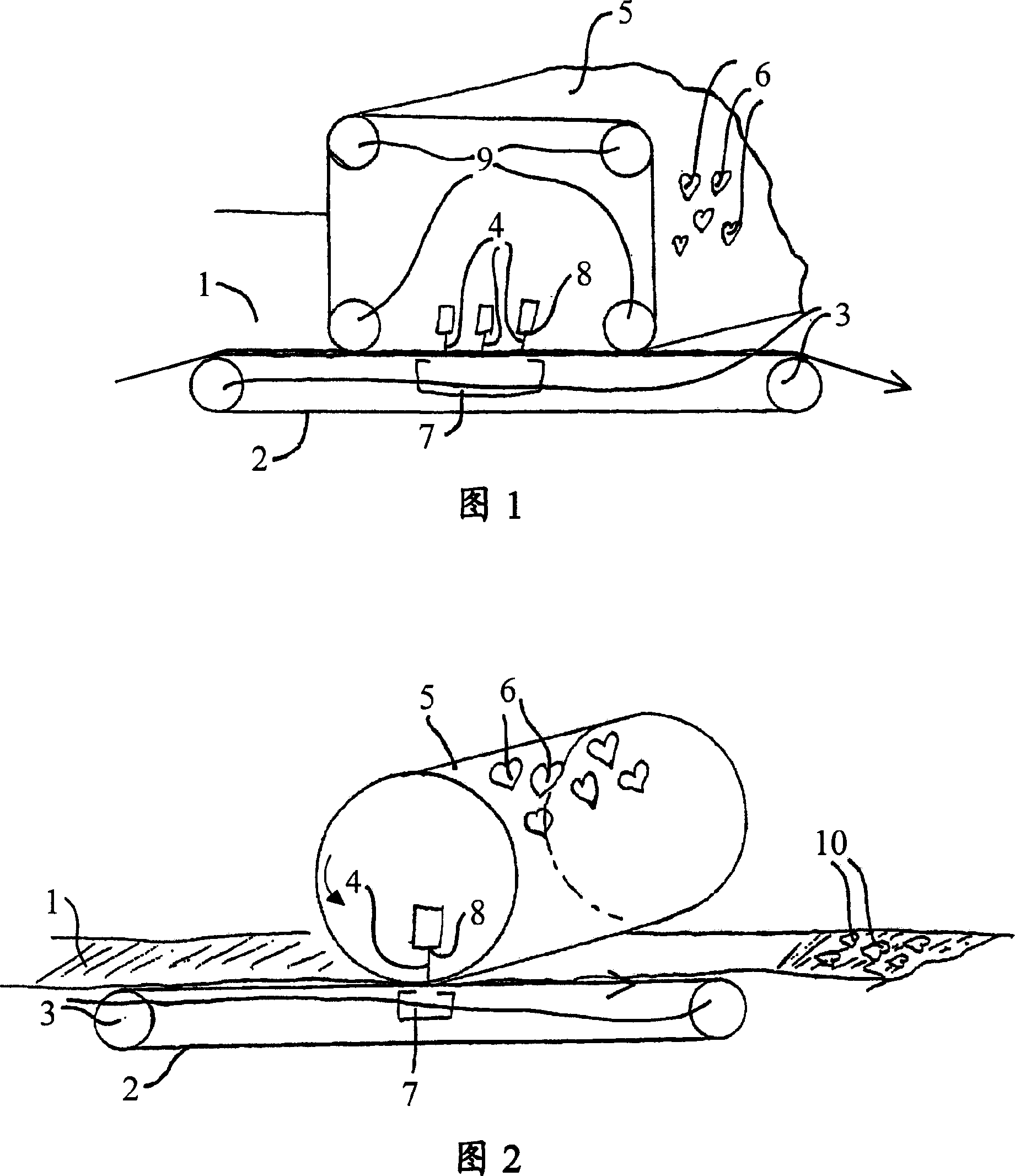

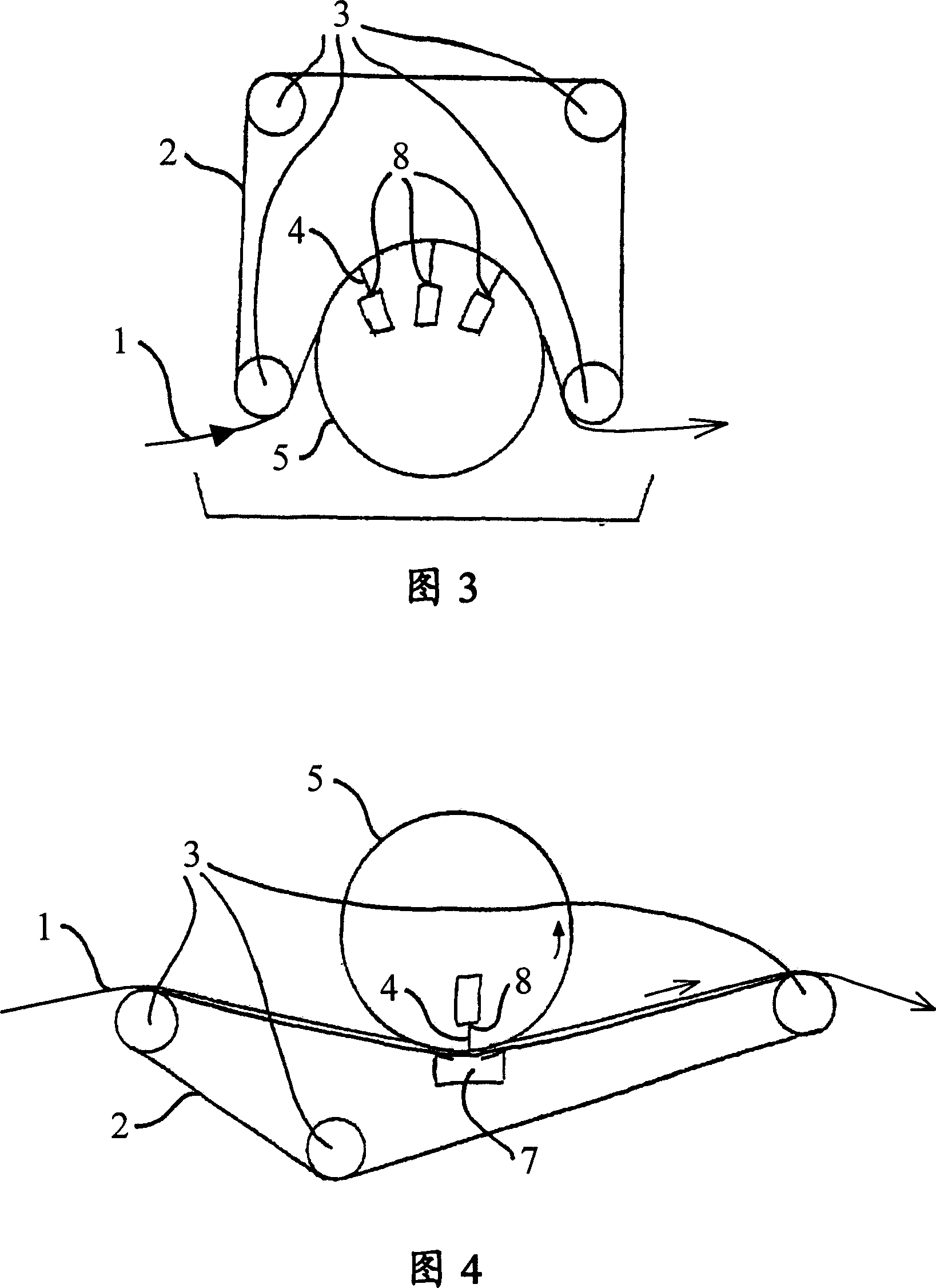

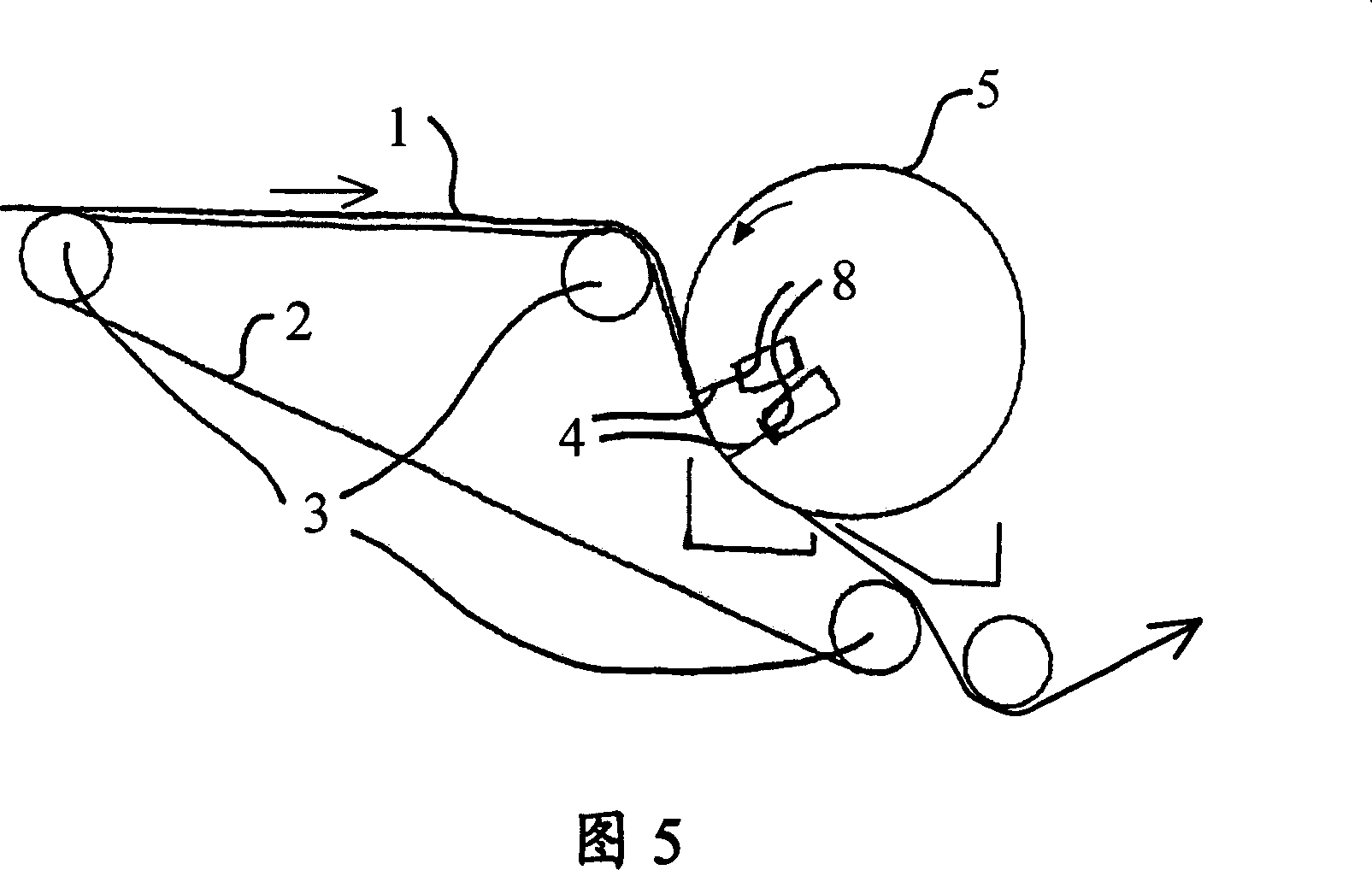

[0018] FIG. 1 shows a device according to the invention for producing a plurality of heart-shaped patterns on a fabric web 1 , in which device the template 5 is designed as a tape. The belt is moved by four cylindrical rollers 9 as a continuous strip with a plurality of openings 6 defined in the shape of small hearts. The dyed cloth 1 is conveyed in the direction of the arrow from left to right between the carrier part 2 and the strip template 5 , wherein the carrier part moves on two other cylindrical rollers 3 . Simultaneously, a jet distributor (not shown) sprays a plurality of columnar fluid jets 4 vertically through a plurality of openings 6 of the template 5 onto the fabric web 1 from a plurality of injection openings 8 . The suction box 7 is located below the injection port 8 and the carrying membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com