Annular extension limit flexible pressurized grouting bolt

An anchor rod and flexible technology, applied in the installation of anchor rods, construction, mining equipment, etc., can solve the problems of insufficient strength and unlimited hoop deformation, and achieve the effect of enhancing the overall strength, improving the fastening effect, and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

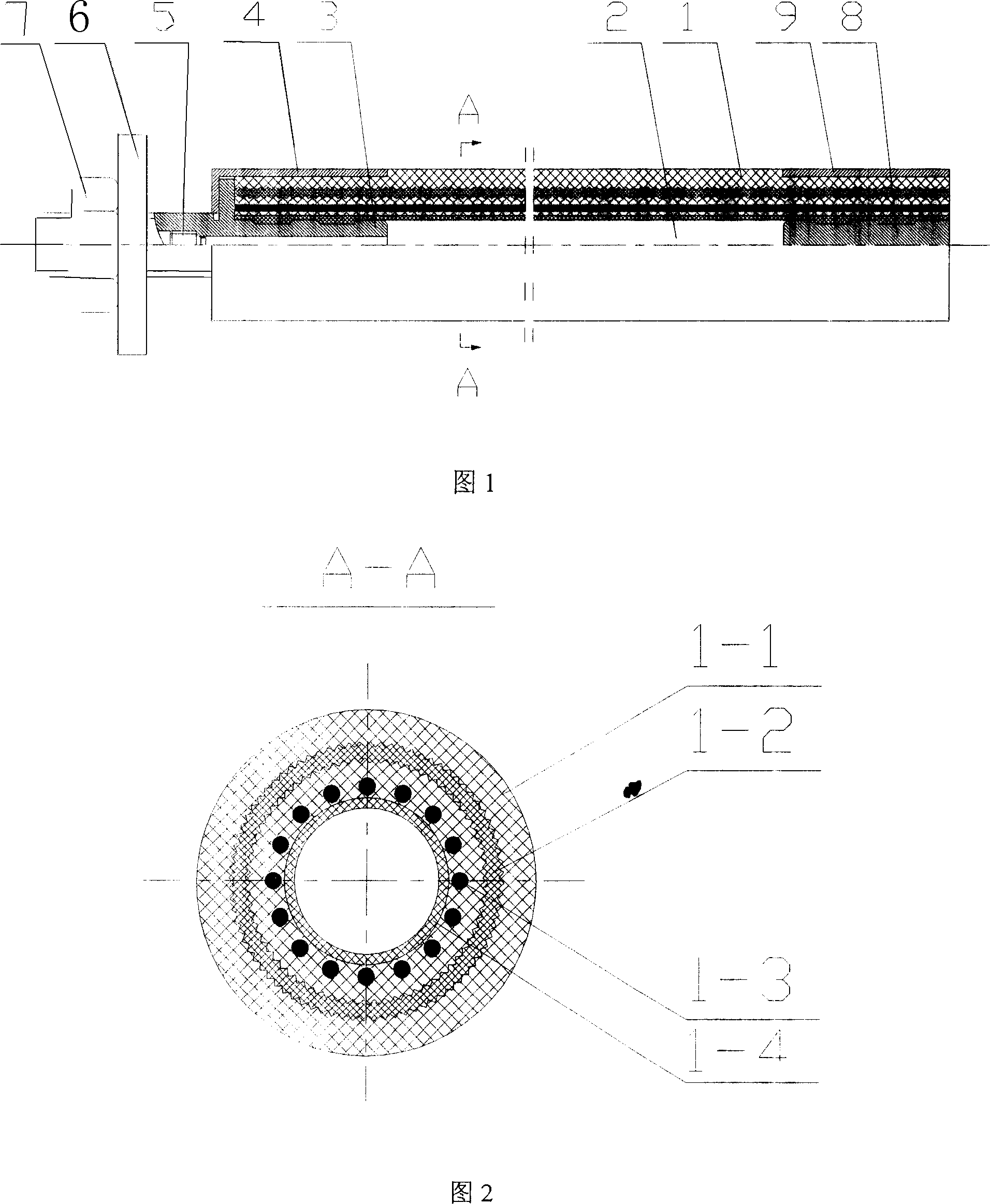

[0017] The best embodiment, as shown in Figure 1 and Figure 2:

[0018] Take the bolt commonly used in coal mines as an example. Coal mines usually use a drill bit with a diameter of 28mm to drill the anchor hole to place the anchor rod. In order to facilitate the installation of the flexible injection anchor rod, the diameter of the anchor rod body is slightly smaller than the diameter of the drill bit, which is determined to be 27mm. The diameter of the injection cavity is 14mm, and a mandrel with a diameter of 14mm is selected, and the release agent is coated on the mandrel. The sealing layer 1-4 in the main body of the anchor rod 1 has a thickness of 2.5mm, which is extruded from natural rubber, sleeved or directly extruded On the mandrel; 30 steel strands with a diameter of 1.5mm are selected for the longitudinal reinforcement layer 1-3, and are uniformly distributed on the outer surface of the sealing layer 1-4 along the longitudinal direction of the anchor rod, or extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com