Manufacturing method of diamond coating film and its application

A manufacturing method and diamond coating technology, which are applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of diamond film defects, easy-to-wear substrates, diamond film cracks, etc., to reduce assembly cracks, The effect of reducing thermal stress cracking and improving mechanical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

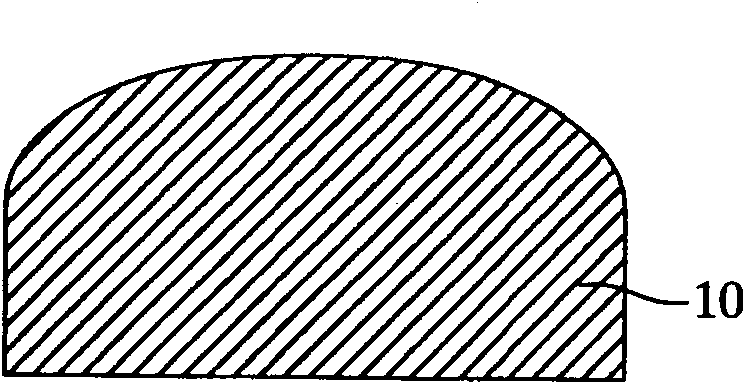

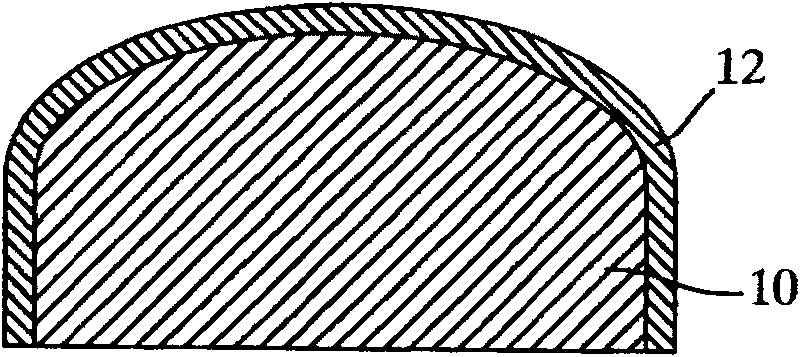

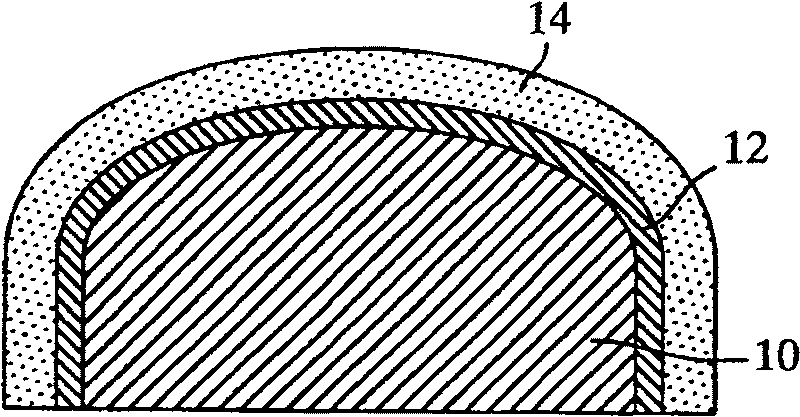

[0021] According to the manufacturing method of the diamond coating disclosed in the present invention, it can be applied to the production of various diamond coatings without any special limitation. Please refer to Figure 1A-1D , take the vibrating membrane as an example to explain in detail.

[0022] Such as Figure 1A As shown, a substrate 10 is provided. The substrate 10 is a material that is easily thermally decomposed and has a heat-resistant temperature of about 200° C. to 400° C., such as a polymer material. Of course, the shape of the substrate 10 matches the required vibration The thickness of the substrate 10 ranges from 0.1 mm to 30 mm. For the thermogravimetric analysis (Thermogravimetric Analysis; TGA) diagram, please refer to figure 2 , when the thermal decomposition temperature is exceeded, the thermal weight will be greatly reduced instantly, as shown in the figure, which is about 400 degrees.

[0023] Then coat a conversion layer 12 on the top of the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com