Laser capable of regulating pulsewidth

A laser and pulse width technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of energy waste, large loss, and high cost, and achieve flexible pulse width adjustment, easy installation and debugging, and simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

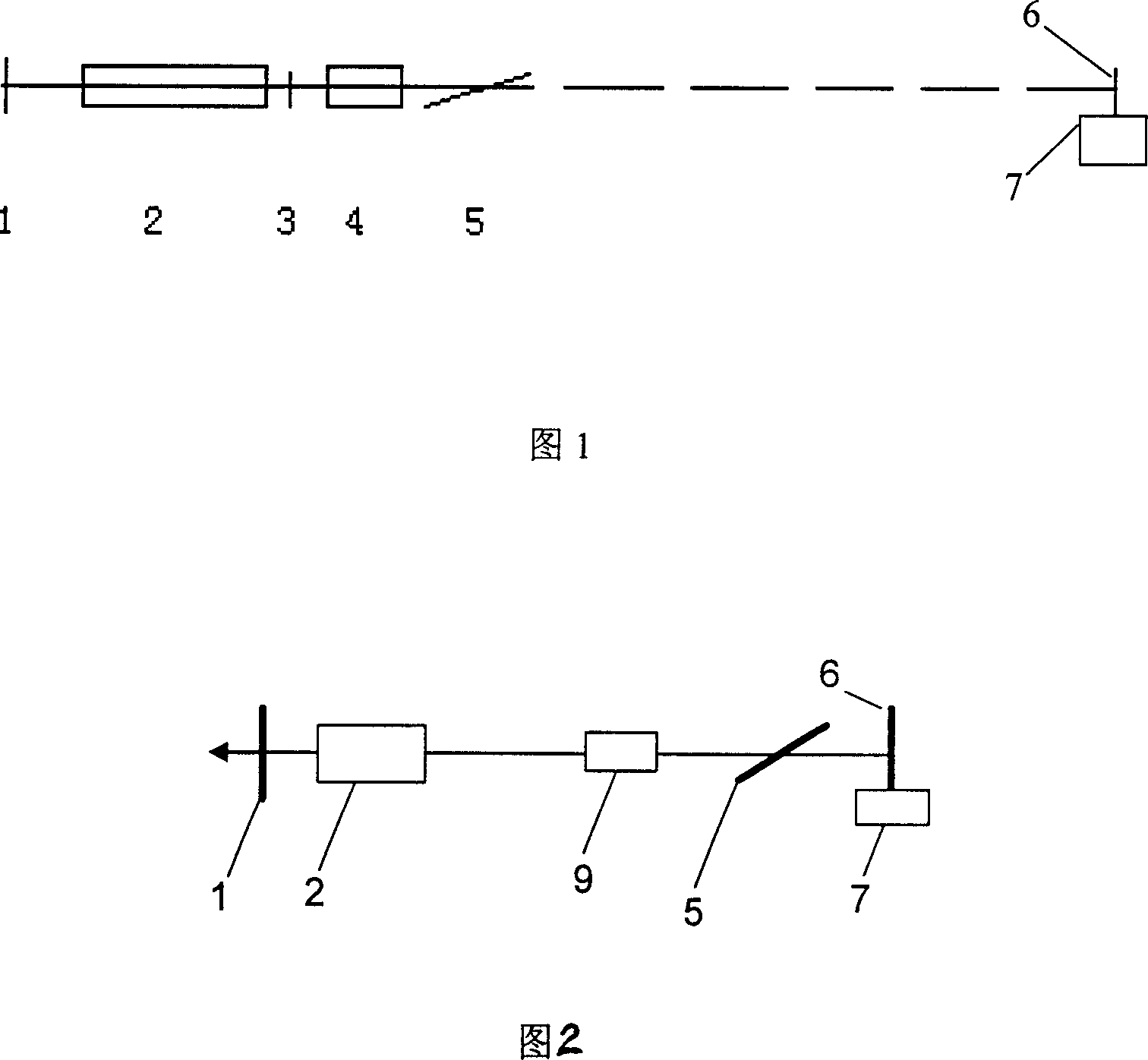

[0024] Referring to Figure 1, an electro-optic Q-switched pulse width-tunable laser is produced, including an output mirror 1, a laser rod 2, a 1 / 4 wave plate 3, a step-up electro-optic Q-switched Pockels cell 4, a polarizer 5, and a total reflection mirror 6. Moving stage 7. A pump source for exciting the laser rod 2. The polarization direction of the polarizer 5 is horizontal, and the angle between the plane of the polarizer 5 and the optical axis of the laser is Brewster's angle.

[0025] The material of the output mirror 1 is K9 glass or fused silica, coated with a dielectric film with a certain transmittance, for example, the transmittance T=90%. The material of the laser rod 2 is Nd:YAG, and the doping concentration is selected as 1%. The material of the step-up electro-optic Q-switched Pockels cell 4 is KD * P crystal, KDP or other Q-switching crystals can also be used, and the size only needs to be slightly larger than the diameter of the laser crystal rod. In this e...

Embodiment 2

[0031] Replacing the total reflection mirror 6 with a corner cube, and applying the corner cube in the laser cavity is competent for those skilled in the art, and the others are the same as in Embodiment 1. As disclosed in the document "Intense Lasers and Particle Beams, Volume 16, Issue 8, "Basic Characteristics of Corner Cube Laser Resonators", corner cube prisms have the advantages of self-stabilization, no need for debugging, and strong anti-detuning ability. Therefore, the laser in this embodiment has the advantages of self-stabilization, no need for debugging, strong anti-detuning ability, and the like. By operating the electric stage in a known manner, the corner cube is controlled to move along the optical axis, so as to realize the transformation of the length of the cavity. Because the length of the resonant cavity is the key factor affecting the laser pulse width, changing the cavity length can realize the change of the laser pulse width. When a short pulse needs t...

Embodiment 3

[0033] What embodiment 1 and embodiment 2 used all is the Pockels cell 4 of step-up electro-optic Q-switching. The Pockels cell 4 in this embodiment is a step-down electro-optic Q-switched Pockels cell, as shown in FIG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com