Method for producing directionally solidified silicon ingots

A technology for directional solidification and polycrystalline silicon ingots, which can be used in self-solidification methods, chemical instruments and methods, self-area melting methods, etc., and can solve problems such as reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 (prior art)

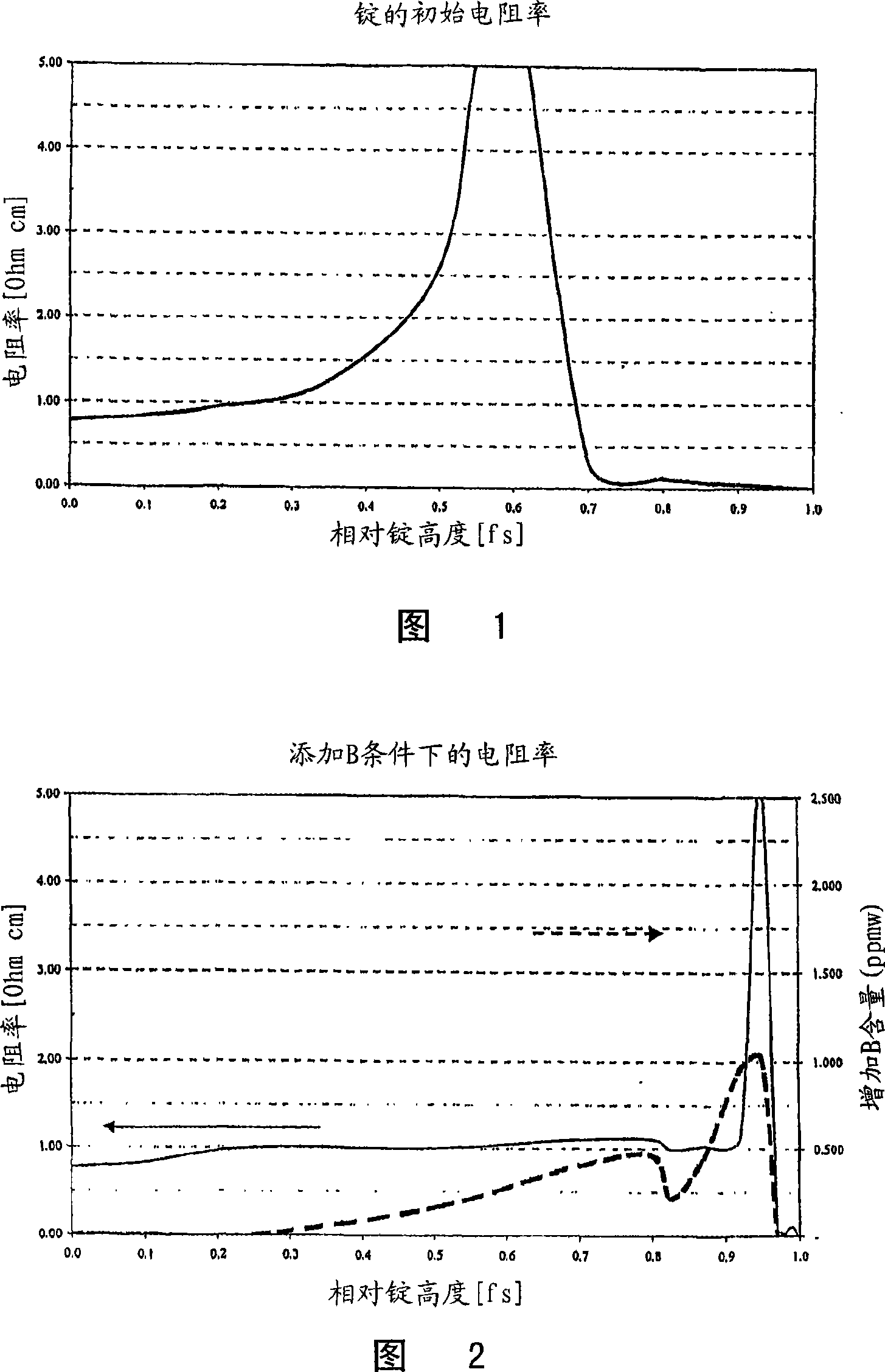

[0013] Directional solidified silicon ingots were produced from a silicon feedstock initially containing 0.8 ppma boron and 3.6 ppma phosphorous. The transition from p-type material to n-type material in a silicon ingot occurs at approximately 60% of the height of the solidified ingot. The resistivity of the as-prepared silicon ingot is shown in Figure 1, from which it can be seen that the transition from p-type material to n-type material occurs at about 60% of the ingot height.

Embodiment 2

[0014] Embodiment 2 (the present invention)

[0015] The same silicon raw material in Example 1 was used to prepare directionally solidified silicon ingots. Boron is continuously added to the remaining molten silicon when approximately 50% of the ingot has solidified. As can be seen in Figure 2, the transition from p-type material to n-type material occurs at greater than 90% of the height of the solidified ingot. The amount of boron added to the silicon melt is also shown in FIG. 2 .

[0016] By comparing the results of Example 1 and Example 2, it can be seen that the transition from p-type material to n-type material moves from about 60% of the ingot height to greater than 90% of the silicon crystal height.

[0017] Thus, with the present invention, it is possible to significantly increase the fraction of directionally solidified ingots (solidified as p-type material or n-type material).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com