Fluid pressure circuit, energy recovery device, and fluid pressure recovery circuit for working machine

A fluid pressure and energy regeneration technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve the problem of reduced operating speed, inability to set up mutual complementary working fluid support circuits, and inability of boom cylinders to work. Stability and other issues, to achieve the effect of suppressing sudden load fluctuations, realizing stable operation, and suppressing load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

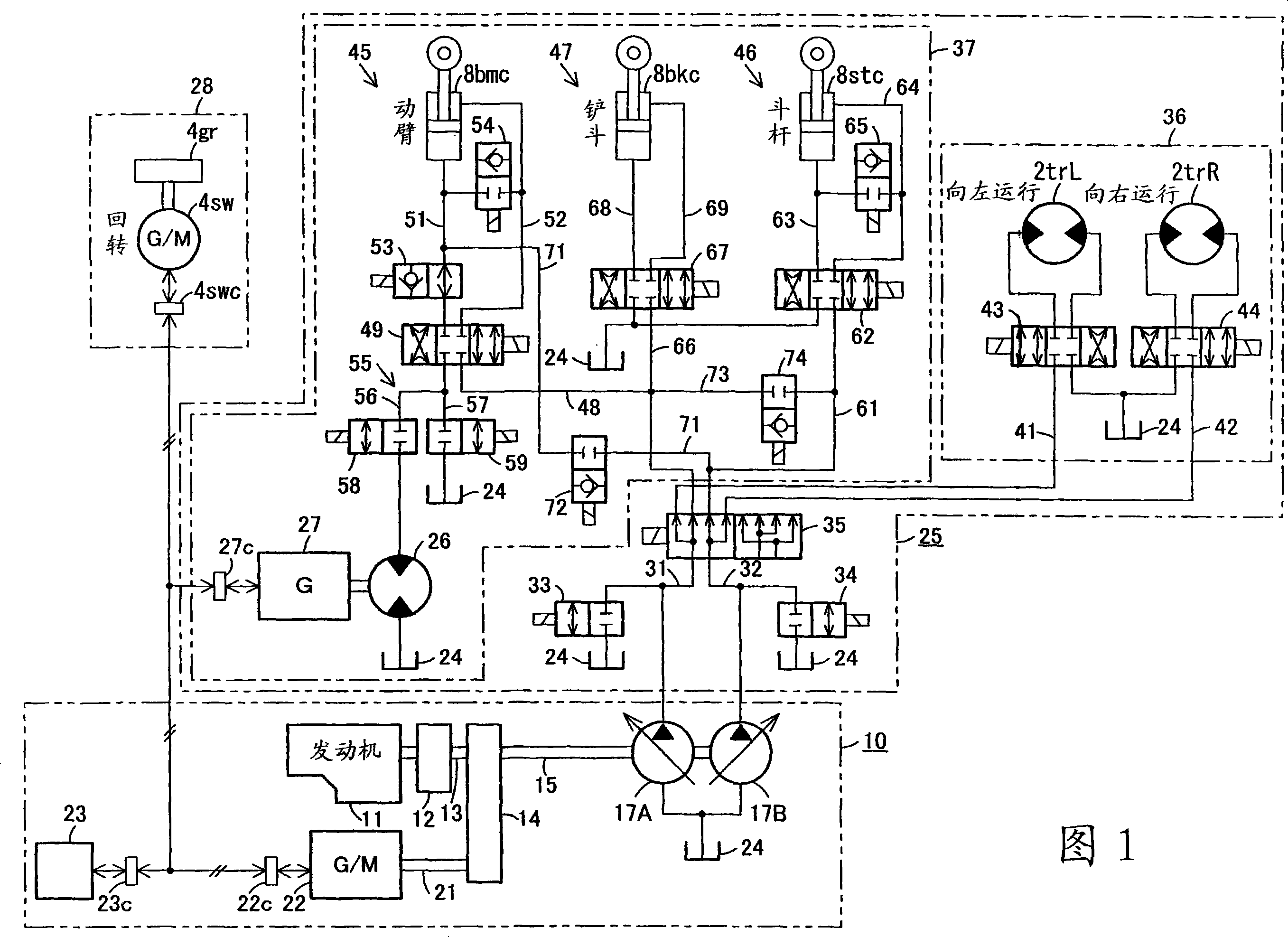

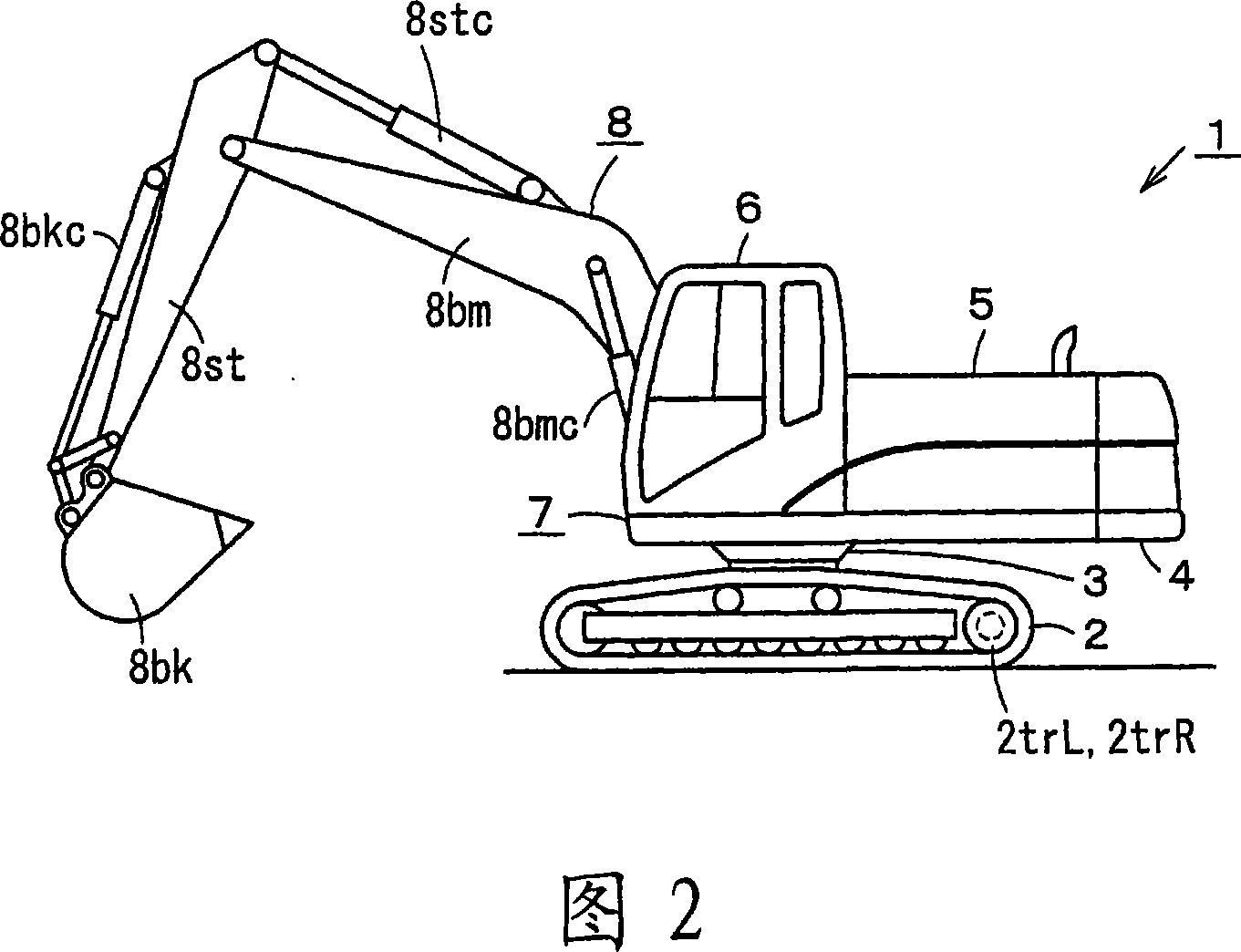

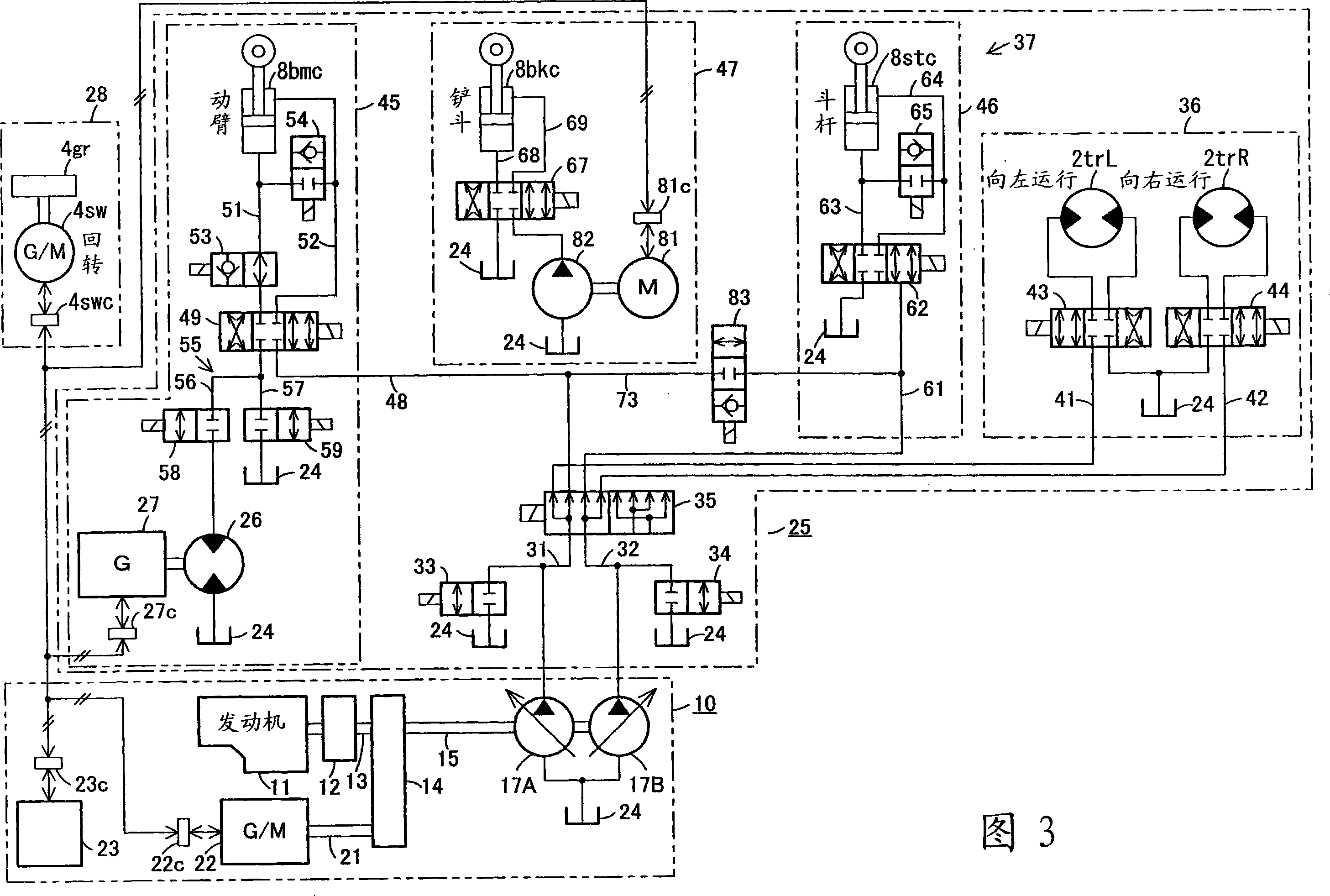

[0036] Hereinafter, referring to the first embodiment shown in FIGS. 1 and 2 , the second embodiment shown in FIG. 3 , the third embodiment shown in FIG. 4 , the fourth embodiment shown in FIG. 5 , and the second embodiment shown in FIG. The fifth embodiment shown in FIG. 7 , the sixth embodiment shown in FIG. 7 , and a modified example of the hybrid drive device shown in FIG. 8 will be specifically described for the present invention.

[0037] First, a first embodiment shown in FIGS. 1 and 2 will be described.

[0038] As shown in Figure 2, the working machine 1 is a hydraulic excavator, and an upper rotating body 4 is freely rotatably provided on the lower running body 2 through a rotating bearing part 3, and an engine and a fluid pressure are installed on the upper rotating body 4. A power unit 5 such as a pump, a cab 6 for protecting an operator, and the like form a machine body 7 . The lower running body 2 has running motors 2trL, 2trR for driving the left and right craw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com