Corrosion inhibitor in use for lubricating oil in esters

A technology of lubricating oil and corrosion inhibitor, which is applied in the field of ester lubricating oil, can solve the problems of immiscibility, small acid value of corrosion inhibitor, low polarity, etc., and achieve good reproducibility, excellent thermal stability, and good dissolution sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

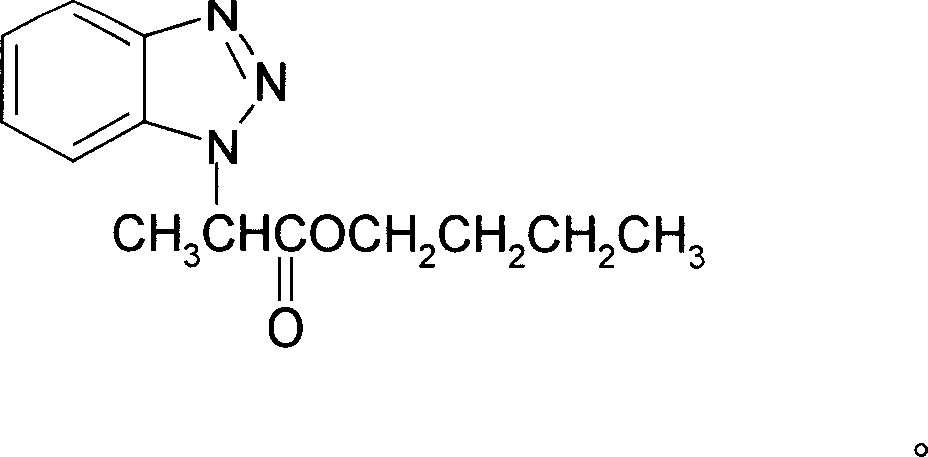

[0021] 1.1 The present invention is prepared according to the following reaction formula:

[0022]

[0023] Mechanical stirring is housed, thermometer, in the 10L three-necked round-bottomed flask of reflux condenser, drop into the benzotriazole of 2383g (20mol), the n-butyl acrylate of 3332g (26mol), 80g free radical inhibitor hydroquinone, 4000ml of toluene, reflux at 130°C for 10h, replace the distillation device, and recover the toluene and unreacted materials by atmospheric distillation. Raise the temperature to collect fractions at 178-180° C. / 3-5 mmHg to obtain about 4742 g of crude product (yield 96%). Dissolve the crude product in 9000ml of toluene, wash with 4% 4160g aqueous sodium hydroxide solution to remove the polymerization inhibitor, separate the water phase, wash the organic phase twice with 4% aqueous sodium chloride solution, wash once with distilled water, separate The organic phase was concentrated and recovered toluene. Then add 200g of basic alumina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com