Liquid engine

An engine and fluid technology, applied in the direction of engine, wind turbine, machine/engine, etc., can solve the problems of high cost, inconvenient maintenance and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

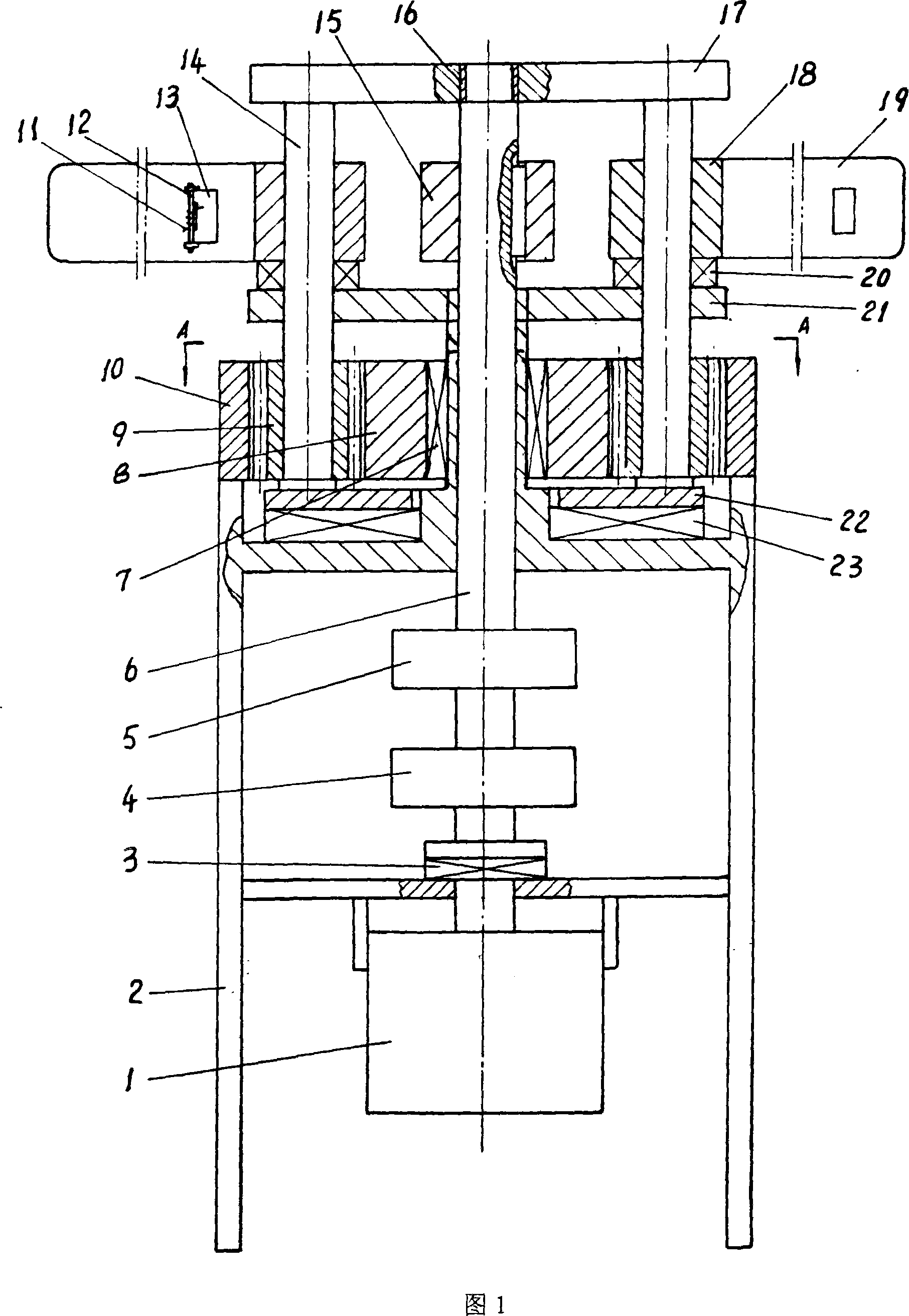

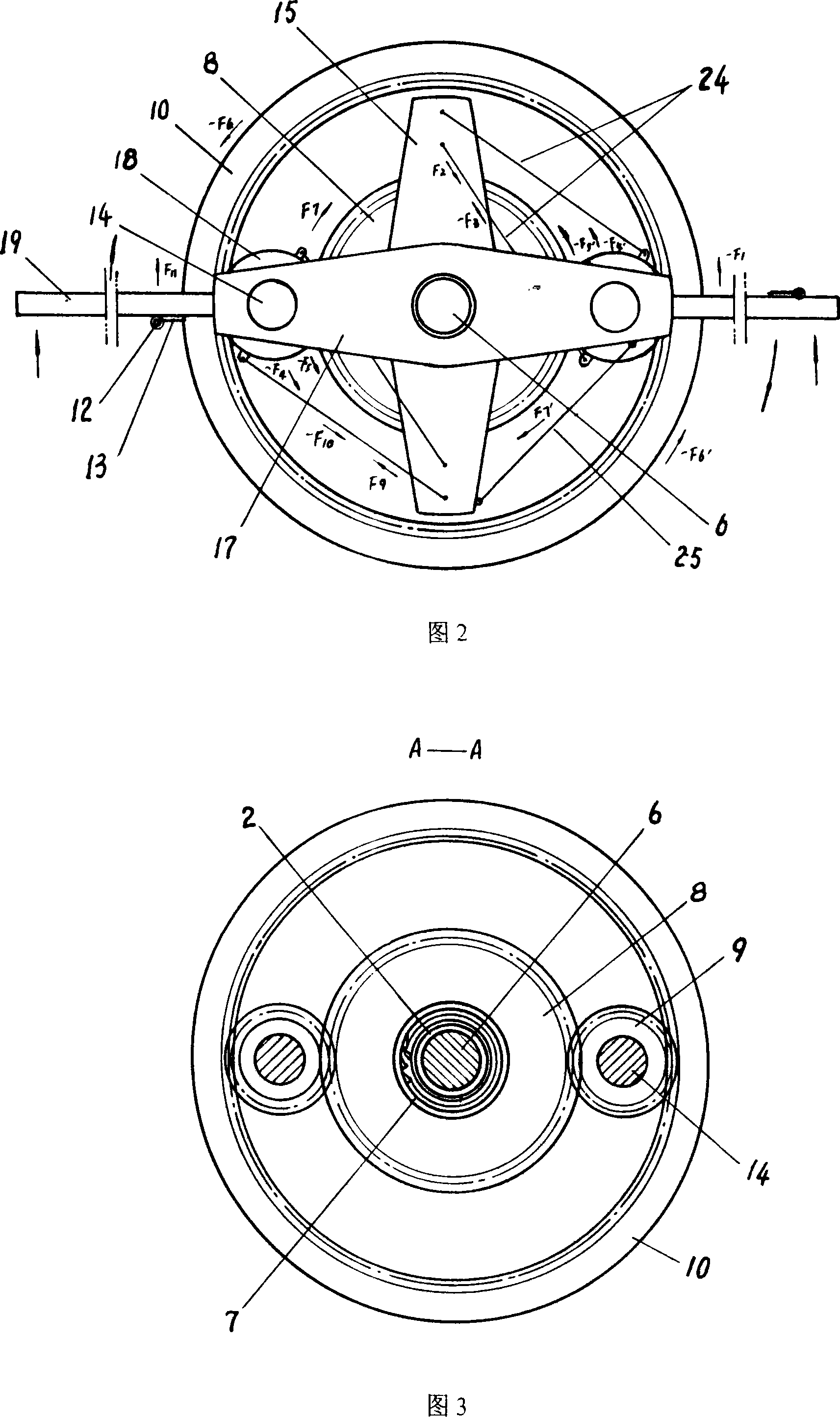

[0015] The present invention will be described in further detail below in conjunction with embodiment accompanying drawing:

[0016] Referring to accompanying drawing, a kind of fluid engine provided by the present invention comprises the power take-off shaft 6 that is arranged in vertical direction, two straight blades 19 and frame 2 in its composition, and frame 2 upper end fixes a tooth along horizontal direction ring 10, the ring gear 10 is internally meshed with a pair of symmetrically arranged planetary gears 9, and the two planetary gears 9 are meshed with a sun gear 8, and a one-way clutch 7 is set between the sun gear 8 and the frame 2, as shown in the figure One-way clutch 7 is internal meshing type ratchet, ratchet one-way clutch, and clutch inner ring is fixed with frame 2, and outer ring is fixed with central gear 8. The effect of the one-way clutch 7 is to guarantee that the central gear 8 is consistent with the direction of rotation of the engine, and simultaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com