Nuclear plant pressure vessels steel irradiation post-impacting test automated device

An automatic device and pressure vessel technology, applied in nuclear power generation, measuring devices, instruments, etc., can solve the problems of high cost, indirect alignment and complex motion trajectory, complex structure, etc., to save costs, reduce sample delivery steps and other problems. The effect of the actuator and the simplification of the sample delivery trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with embodiment.

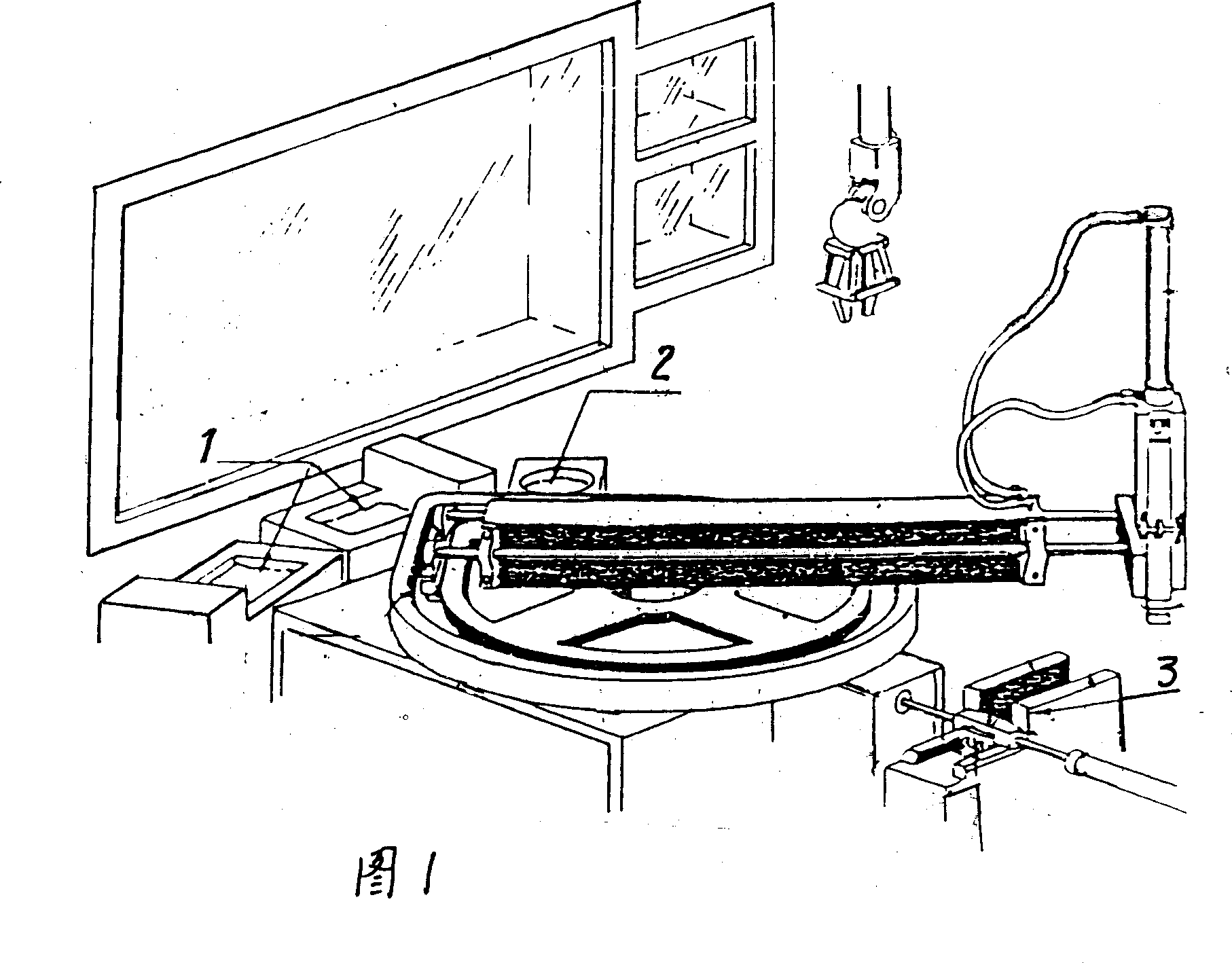

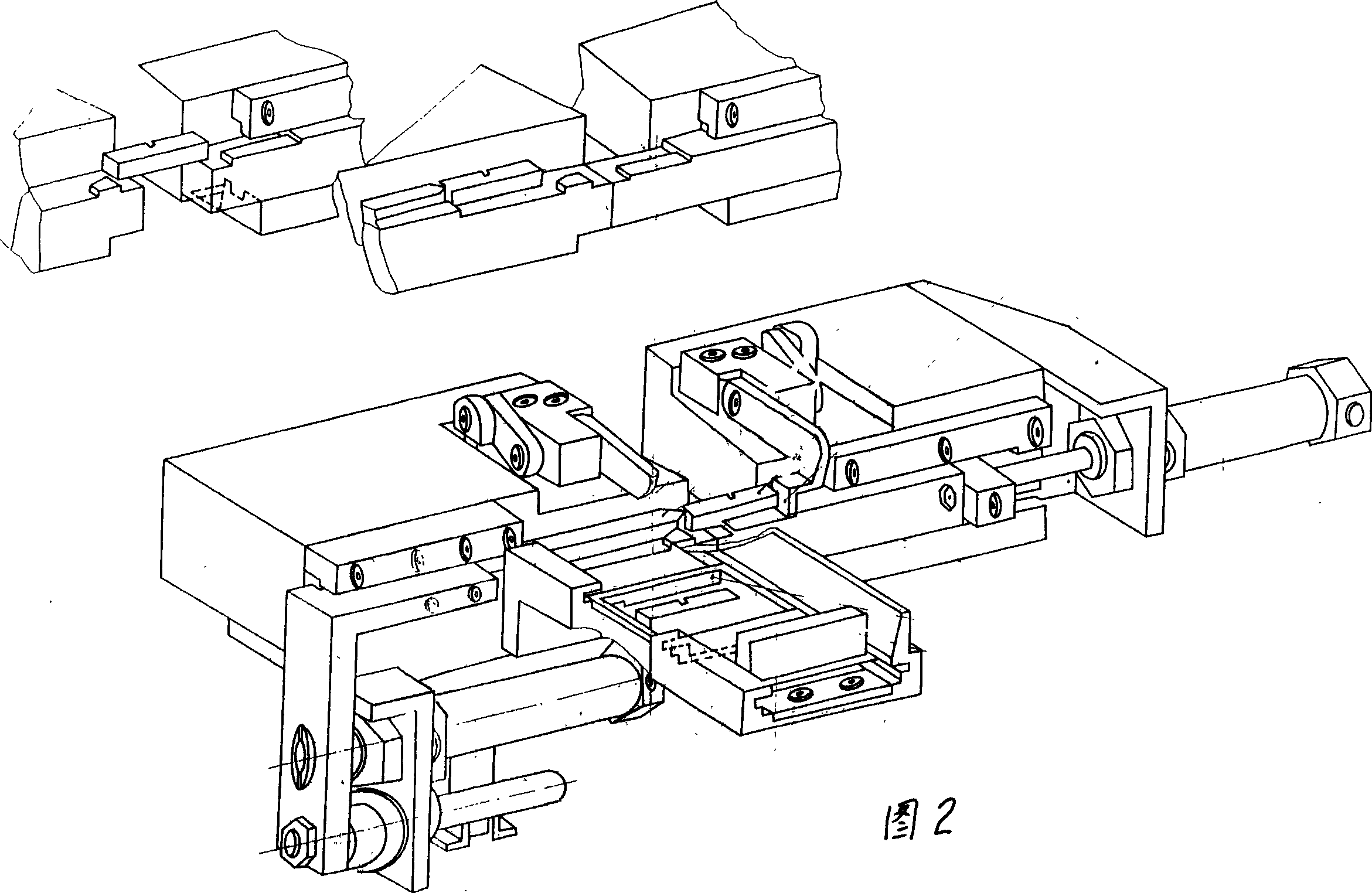

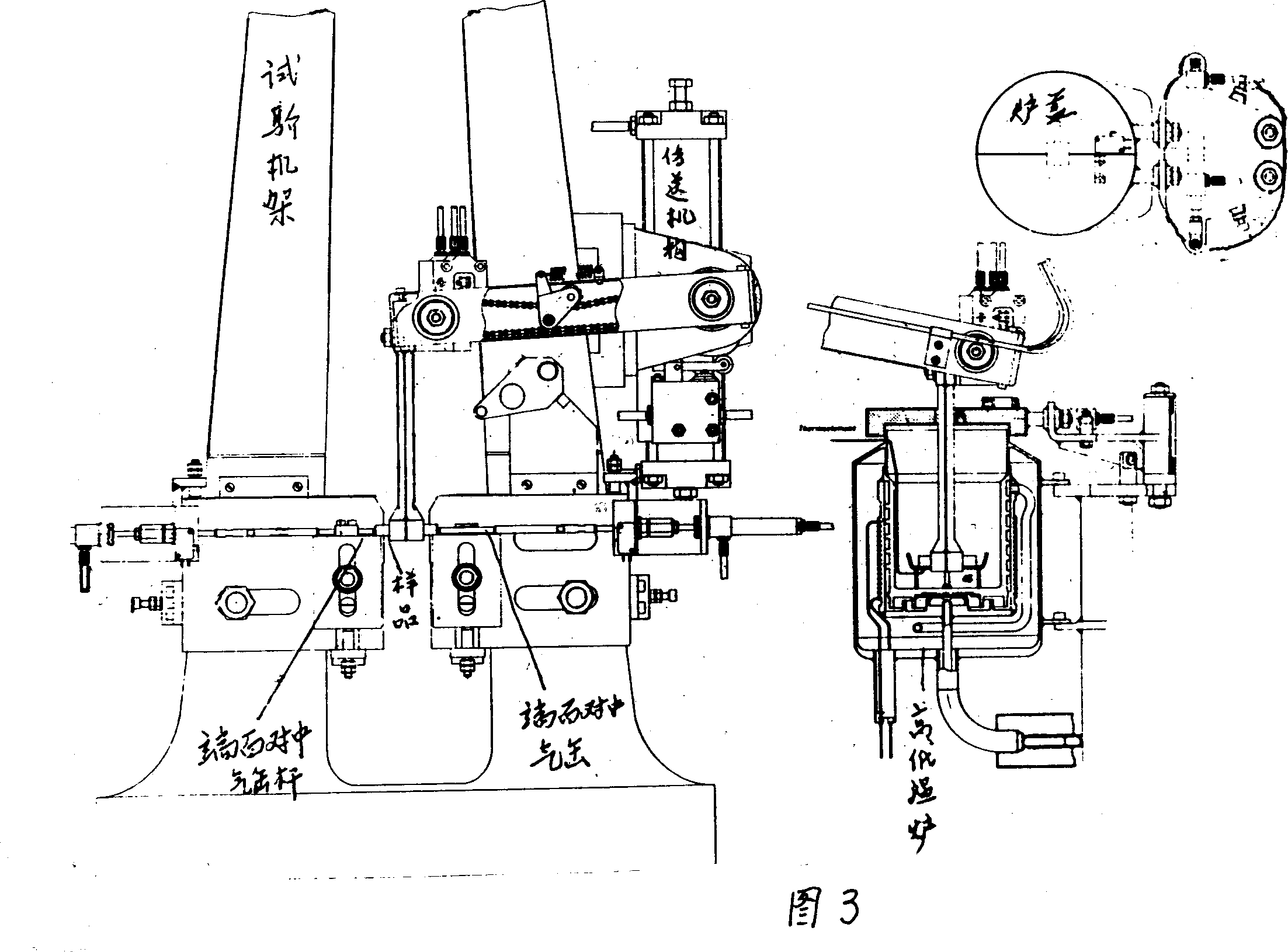

[0023] In order to better describe the present invention, the operation and working process of the equipment of the present invention will be described below. First start the electronic switch to lift the pendulum of the oscillometric impact machine 4 to the designated position, and send the sample into the bath furnace 5; secondly, according to the needs of the test, the sample is heated or cooled through the bath furnace 5; The detector detects the temperature of the upper and lower surfaces of the sample. When the surface temperature of the sample reaches the requirement and the temperature control accuracy is kept within ±2°C for 20 minutes, the impact test can be started; the electronic switch is activated through the console, and the sample push plate pushes the sample along the guide rail. Move forward until it is in close contact with the centering device 6. When the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com