Industrial producing method and device for diluting concentrated nitric acid

A production device, a technology for concentrated nitric acid, applied in the directions of nitric acid, nitrogen oxides/oxyacids, etc., can solve problems such as hidden dangers in production safety and material bumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

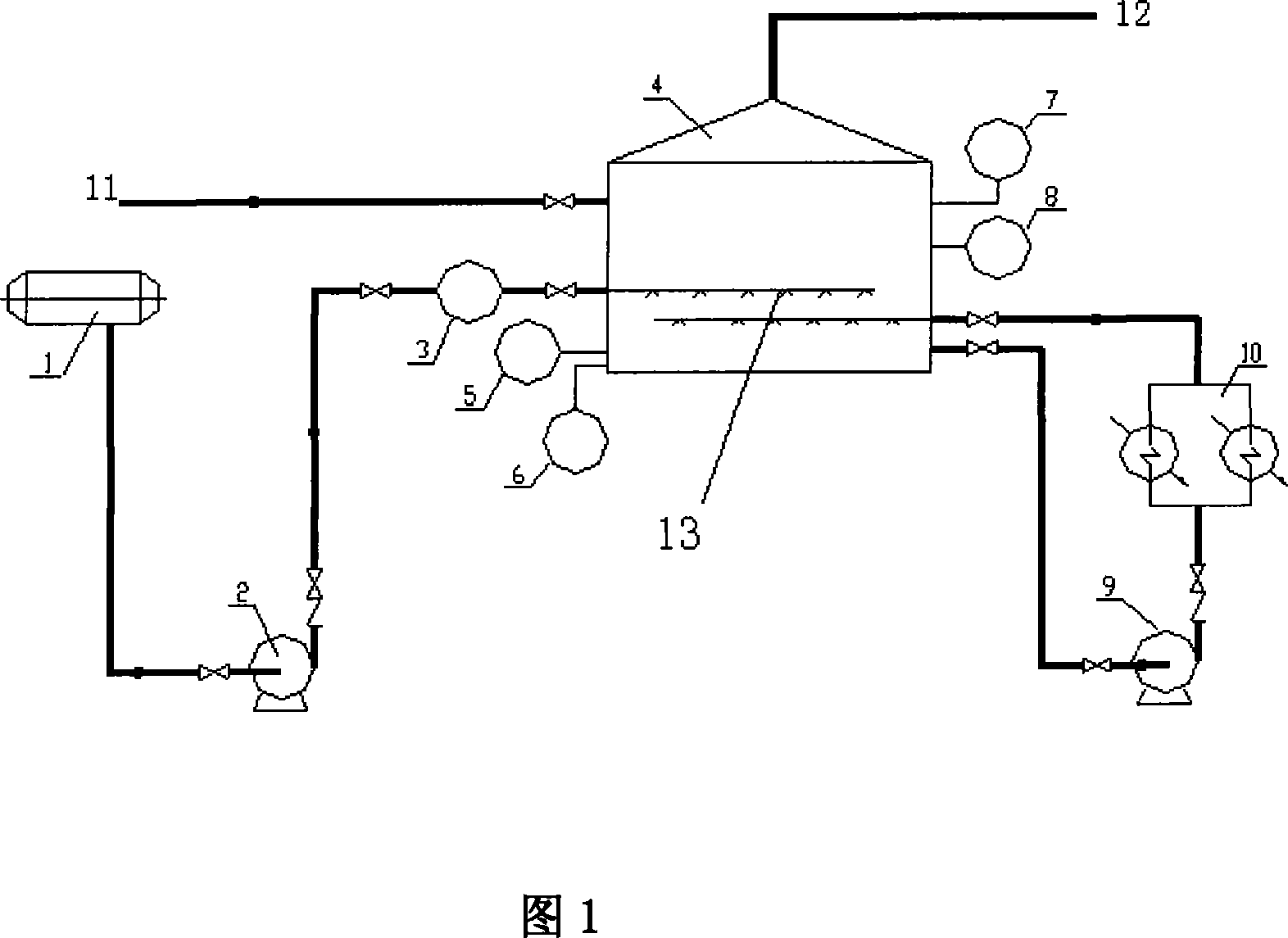

[0019] The scheme of the present invention will be specifically described below according to the accompanying drawings.

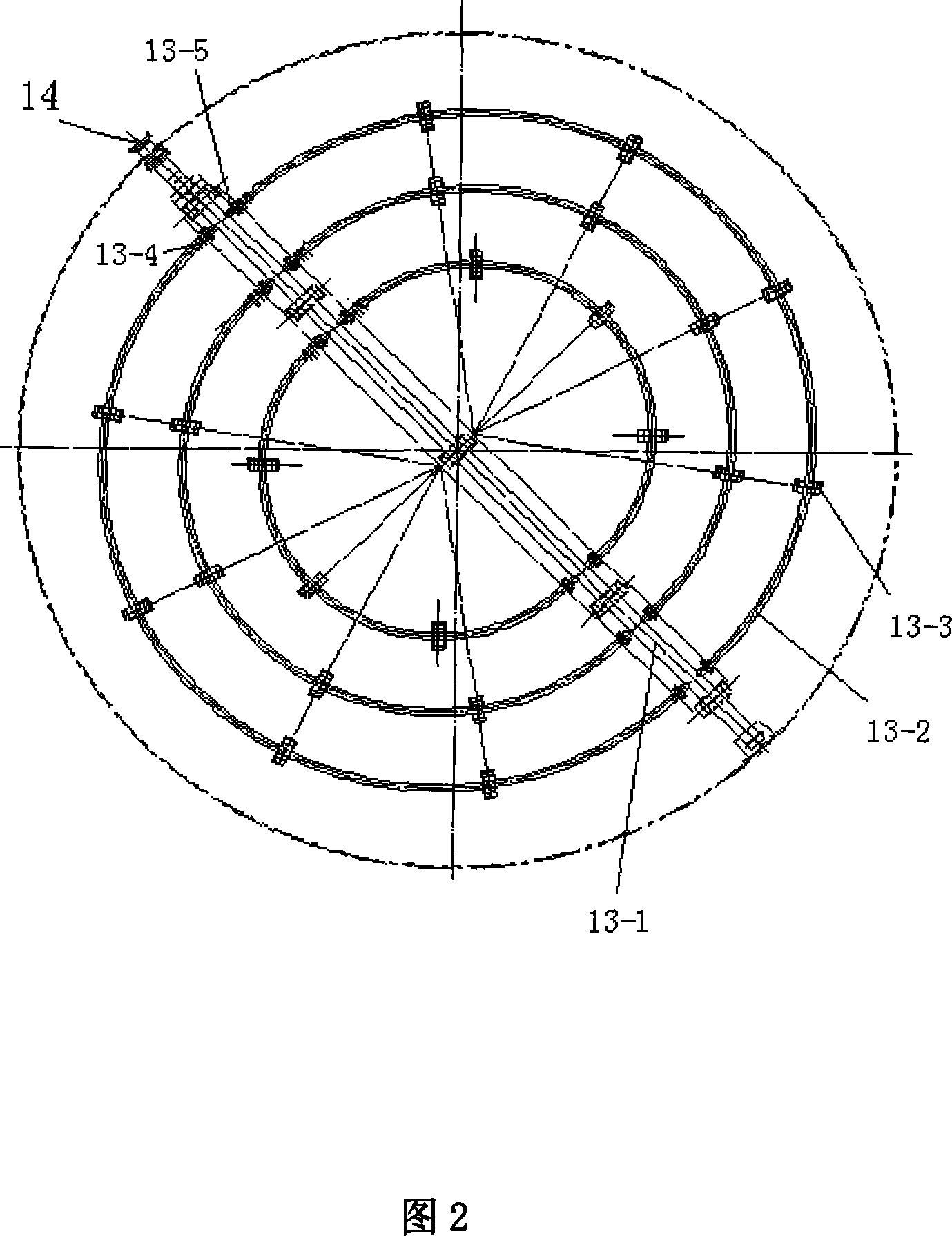

[0020] The concentrated nitric acid dilution is carried out in the concentrated nitric acid dilution tank. The concentrated nitric acid dilution tank 4 is a cylindrical cylinder, and a distributor 13 is installed in the middle and upper part of the cylinder body. The connected concentrated nitric acid dilution main pipe 13-1 and several circles of dilution distribution pipes 13-2 are composed. The concentrated nitric acid dilution main pipe 13-1 is located in the middle of the distributor 13, and there are connecting holes 13- 5. The dilution distribution pipe 13-2 is connected to the connection hole 13-5 on the concentrated nitric acid dilution main pipe 13-1, and several evenly distributed small drainage holes 13-4 are opened on the lower side of the dilution distribution pipe 13-2. The distributor is suspended and fixed in the tank by the bracket 13-3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com