Method and apparatus for producing natural gas through combination of smashed coal pressurized gasification and dry-process entrained-bed gasification

A crushed coal pressurized gasification and co-production technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of high production and operation costs, weak market competitiveness, and low added value of products, and achieve the ability to adjust production and operation strong, reducing investment and production and operating costs, and solving the bottleneck problem of coal selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

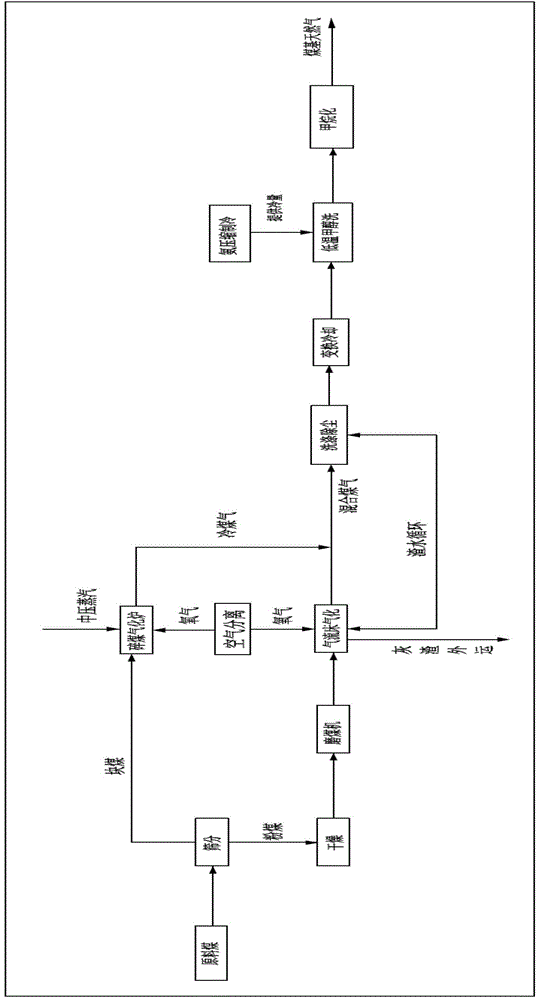

[0057] see figure 1 As shown in the flow chart, this embodiment describes a specific implementation of the method and device for producing natural gas by pressurized gasification of crushed coal combined with dry entrained gasification of the present invention.

[0058] The specific operation is as follows:

[0059] In this example, the pressure gasification of crushed coal adopts a gasification agent composed of lignite with a particle size of 13-50 mm, water vapor and pure oxygen, and is carried out in countercurrent contact in a pressure gasifier of crushed coal under a pressure of 3.0 to 4.1 MPa. Gasification reaction, the temperature of the coal gas exiting the gasifier is about 225-600°C, and the main components of the reaction product are CO, H 2 , CO 2 、CH 4 and undecomposed water vapor with a small amount of C n h m , N 2 , sulfide (mostly H 2 S), tar, naphtha, phenol, fatty acid, ammonia, naphthalene and other mixtures.

[0060] Specifically, the crushed coal...

Embodiment 2

[0067] By the process method described in the above embodiment 1, with daily output 400 * 10 4 N m 3 The calculation of the natural gas project, the economic benefits are as follows:

[0068] (1) Investment cost:

[0069] In the first phase of the project, the investment in 4 sets of gas-water separation and 2 sets of phenol recovery projects (including equipment purchase, installation engineering and construction engineering) is 336 million yuan.

[0070] (2) Annual production benefit:

[0071]1. The operating cost of wastewater pretreatment is about 30 yuan / t waste water×30t / furnace×8000 hours=7.2 million yuan;

[0072] 2. According to the oil produced mainly by the pressurized gasification and carbonization of crushed coal, all of them are converted into gas, and the calculated gas yield is 1.09NM 3 / kg, while the original design gas yield is 0.965NM 3 / kg;

[0073] (1.09-0.965)×40287kg×8000 hours=40.29 million NM 3 ÷3.738=10.78 million NM 3 × 2.7 yuan = 29.11 milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com