Ceramic solar plate

A ceramic solar panel and ceramic sun technology, applied in the field of solar energy utilization, can solve the problems of low average efficiency, affecting heat collection efficiency, easy to corrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

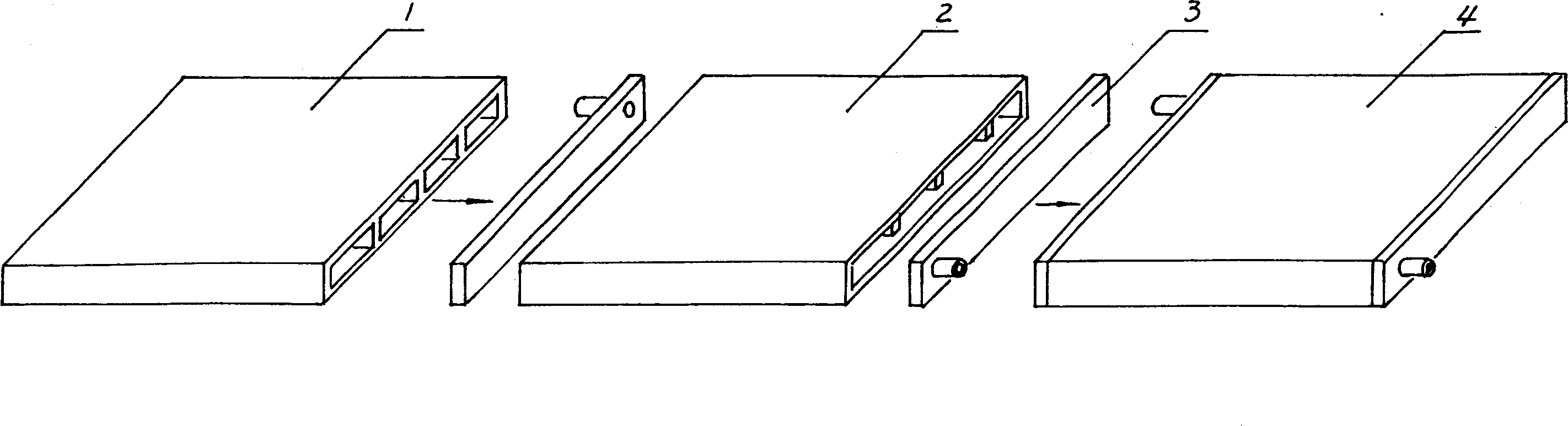

[0028] 1. The ceramic industry usually considers inferior raw materials with iron oxide content of 5% and titanium oxide content of 3.2% to make mud with ordinary ceramic equipment and technology, and vacuum extruder after vacuum refining and aging. Extrude it into a porous through-hole plate body, remove the mud between the two holes at both ends, and make another plug of the same material with an inlet and outlet nozzle and paste it on the two end faces of the multi-hole through-hole plate , so that the nozzles at both ends communicate with each hole in the through-hole plate to form a ceramic solar panel slab, and the slab is dried and fired to become a ceramic solar panel with a gray surface.

[0029] 2. the method as described in embodiment 1, adopts the red clay that iron oxide content is 9%, and the ceramic solar panel that manufactures is red.

[0030] 3. method as described in embodiment 1, adopt common ceramic raw material and ferromanganese slag as raw material, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com